Predictive fleet maintenance leverages historical data and machine learning algorithms to forecast vehicle issues before they occur, reducing downtime and repair costs. Real-time fleet monitoring continuously tracks vehicle performance and location using GPS and IoT sensors, enabling immediate response to operational disruptions. Explore how these innovative technologies transform fleet efficiency and reliability.

Why it is important

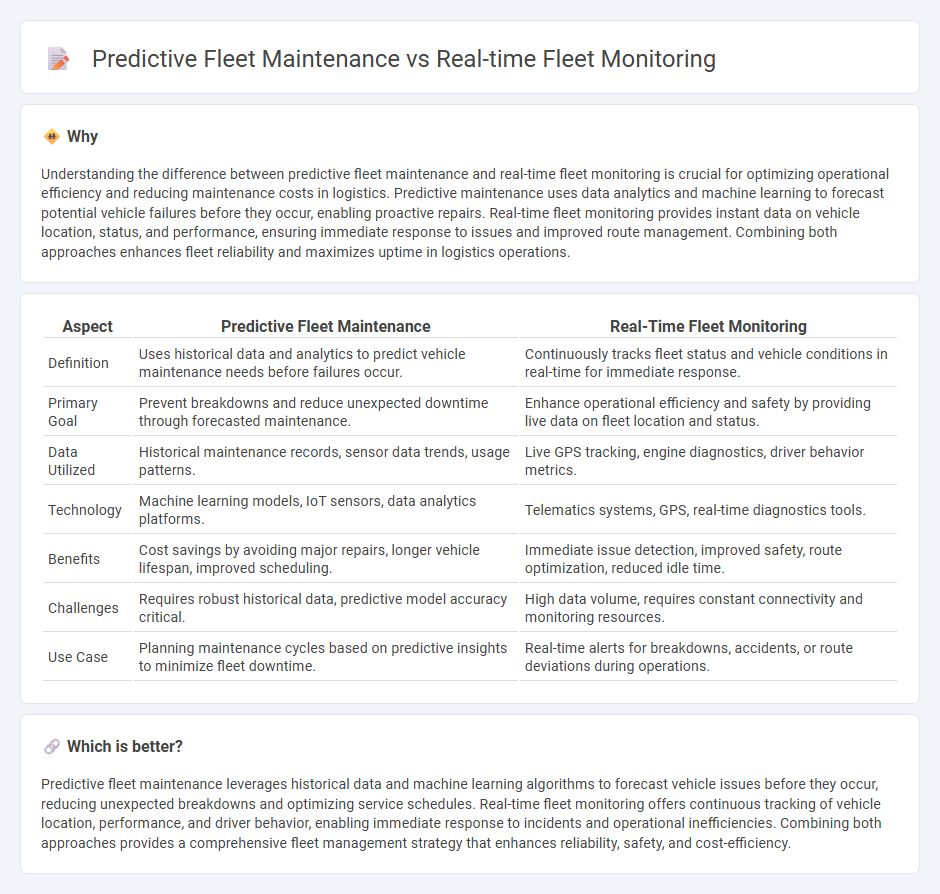

Understanding the difference between predictive fleet maintenance and real-time fleet monitoring is crucial for optimizing operational efficiency and reducing maintenance costs in logistics. Predictive maintenance uses data analytics and machine learning to forecast potential vehicle failures before they occur, enabling proactive repairs. Real-time fleet monitoring provides instant data on vehicle location, status, and performance, ensuring immediate response to issues and improved route management. Combining both approaches enhances fleet reliability and maximizes uptime in logistics operations.

Comparison Table

| Aspect | Predictive Fleet Maintenance | Real-Time Fleet Monitoring |

|---|---|---|

| Definition | Uses historical data and analytics to predict vehicle maintenance needs before failures occur. | Continuously tracks fleet status and vehicle conditions in real-time for immediate response. |

| Primary Goal | Prevent breakdowns and reduce unexpected downtime through forecasted maintenance. | Enhance operational efficiency and safety by providing live data on fleet location and status. |

| Data Utilized | Historical maintenance records, sensor data trends, usage patterns. | Live GPS tracking, engine diagnostics, driver behavior metrics. |

| Technology | Machine learning models, IoT sensors, data analytics platforms. | Telematics systems, GPS, real-time diagnostics tools. |

| Benefits | Cost savings by avoiding major repairs, longer vehicle lifespan, improved scheduling. | Immediate issue detection, improved safety, route optimization, reduced idle time. |

| Challenges | Requires robust historical data, predictive model accuracy critical. | High data volume, requires constant connectivity and monitoring resources. |

| Use Case | Planning maintenance cycles based on predictive insights to minimize fleet downtime. | Real-time alerts for breakdowns, accidents, or route deviations during operations. |

Which is better?

Predictive fleet maintenance leverages historical data and machine learning algorithms to forecast vehicle issues before they occur, reducing unexpected breakdowns and optimizing service schedules. Real-time fleet monitoring offers continuous tracking of vehicle location, performance, and driver behavior, enabling immediate response to incidents and operational inefficiencies. Combining both approaches provides a comprehensive fleet management strategy that enhances reliability, safety, and cost-efficiency.

Connection

Predictive fleet maintenance leverages real-time fleet monitoring data to analyze vehicle performance and anticipate mechanical issues before they cause breakdowns. Sensors and GPS tracking systems provide continuous insights into engine health, tire pressure, and fuel usage, enabling timely maintenance scheduling to reduce downtime. Integrating these technologies enhances operational efficiency, lowers repair costs, and improves overall fleet reliability in logistics management.

Key Terms

**Real-time fleet monitoring:**

Real-time fleet monitoring uses GPS, telematics, and IoT sensors to track vehicle location, speed, fuel consumption, and engine diagnostics instantly, enhancing operational efficiency and safety. It enables immediate response to accidents, unauthorized usage, and route deviations by providing live data streams to fleet managers. Explore the benefits and technologies behind real-time fleet monitoring to optimize your fleet's performance.

Telematics

Real-time fleet monitoring utilizes telematics technology to track vehicle location, speed, fuel consumption, and driver behavior, enabling immediate response to operational issues and enhancing fleet efficiency. Predictive fleet maintenance leverages telematics data combined with machine learning algorithms to forecast potential equipment failures and schedule maintenance proactively, reducing downtime and repair costs. Explore how integrating telematics in these approaches can optimize fleet management and boost operational performance.

GPS tracking

Real-time fleet monitoring leverages GPS tracking to provide instant location data, route optimization, and immediate alerts for deviations, enhancing operational efficiency and safety. Predictive fleet maintenance uses data from GPS and onboard sensors to analyze vehicle health trends, forecast potential failures, and schedule maintenance proactively, reducing downtime and repair costs. Explore how integrating GPS tracking transforms fleet management by combining real-time insights with predictive analytics for optimized performance.

Source and External Links

Zubie: Fleet Management Made Simple - Track your fleet's every move with always-on GPS, real-time alerts, and detailed trip histories, unifying all telematics and GPS data in a simple platform for easy management.

Fleet Tracking System - Real Time Data & Insights - FleetGO(r) - FleetGO's smart fleet tracking provides 24/7 real-time insights into fleet locations, driver behavior, and vehicle performance, enabling optimized operations and instant notifications.

GPS Fleet Tracking Software & Solutions - Samsara - Samsara offers real-time GPS fleet tracking, geofencing, live location sharing, and smart map overlays to improve visibility, operational efficiency, and customer service.

dowidth.com

dowidth.com