Cold chain logistics involves the transportation and storage of temperature-sensitive products such as pharmaceuticals, perishable foods, and chemicals, requiring specialized refrigerated equipment and monitoring systems to maintain consistent temperatures. Dry logistics, on the other hand, caters to non-perishable goods including electronics, textiles, and machinery, focusing on secure packaging and efficient delivery without temperature control. Explore the distinct challenges and solutions within cold chain and dry logistics to optimize your supply chain management.

Why it is important

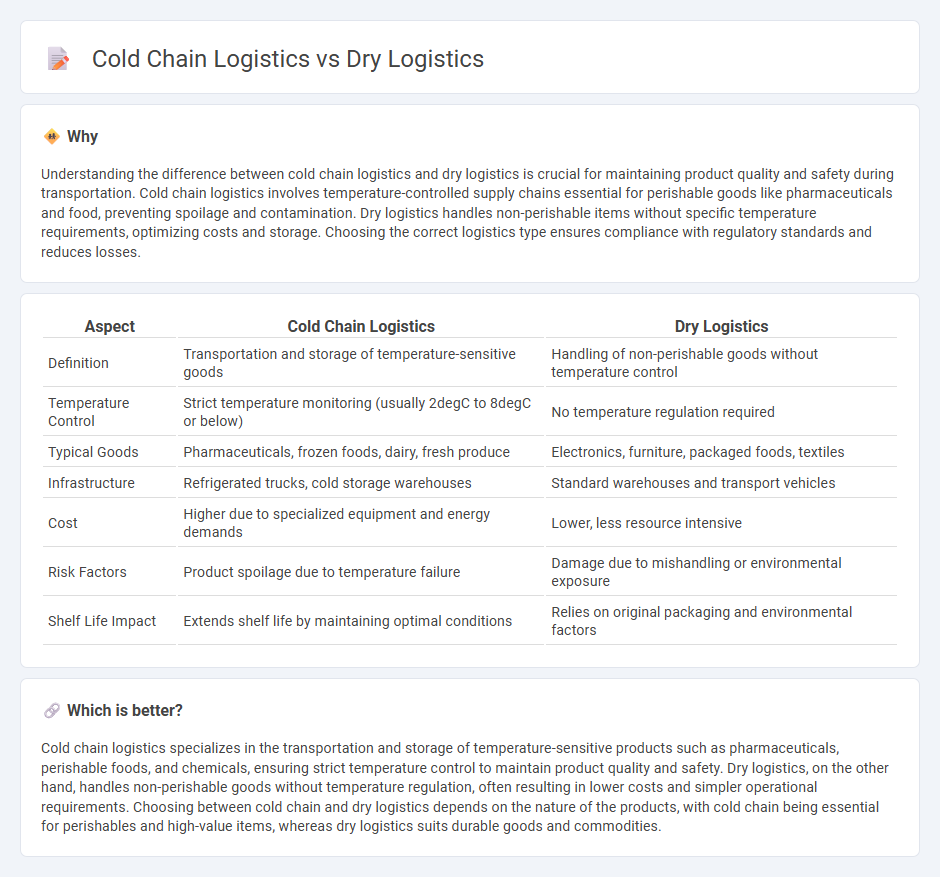

Understanding the difference between cold chain logistics and dry logistics is crucial for maintaining product quality and safety during transportation. Cold chain logistics involves temperature-controlled supply chains essential for perishable goods like pharmaceuticals and food, preventing spoilage and contamination. Dry logistics handles non-perishable items without specific temperature requirements, optimizing costs and storage. Choosing the correct logistics type ensures compliance with regulatory standards and reduces losses.

Comparison Table

| Aspect | Cold Chain Logistics | Dry Logistics |

|---|---|---|

| Definition | Transportation and storage of temperature-sensitive goods | Handling of non-perishable goods without temperature control |

| Temperature Control | Strict temperature monitoring (usually 2degC to 8degC or below) | No temperature regulation required |

| Typical Goods | Pharmaceuticals, frozen foods, dairy, fresh produce | Electronics, furniture, packaged foods, textiles |

| Infrastructure | Refrigerated trucks, cold storage warehouses | Standard warehouses and transport vehicles |

| Cost | Higher due to specialized equipment and energy demands | Lower, less resource intensive |

| Risk Factors | Product spoilage due to temperature failure | Damage due to mishandling or environmental exposure |

| Shelf Life Impact | Extends shelf life by maintaining optimal conditions | Relies on original packaging and environmental factors |

Which is better?

Cold chain logistics specializes in the transportation and storage of temperature-sensitive products such as pharmaceuticals, perishable foods, and chemicals, ensuring strict temperature control to maintain product quality and safety. Dry logistics, on the other hand, handles non-perishable goods without temperature regulation, often resulting in lower costs and simpler operational requirements. Choosing between cold chain and dry logistics depends on the nature of the products, with cold chain being essential for perishables and high-value items, whereas dry logistics suits durable goods and commodities.

Connection

Cold chain logistics and dry logistics intersect in maintaining product integrity during transport by using temperature-controlled environments and dry storage conditions respectively. Cold chain logistics ensures perishable goods like pharmaceuticals and food remain within specified temperature ranges, while dry logistics focuses on preventing moisture damage for items such as electronics and machinery. Integrating both systems optimizes supply chains by managing diverse product requirements efficiently and reducing spoilage or damage risks.

Key Terms

Temperature Control

Dry logistics manages goods that do not require specific temperature regulation, focusing primarily on ambient storage and standard transportation conditions. Cold chain logistics involve a continuous temperature-controlled environment, essential for perishable items like pharmaceuticals, food, and vaccines, ensuring product integrity from origin to destination. Explore further to understand the critical differences and applications of temperature control in supply chain management.

Shelf Life

Dry logistics primarily handles products with longer shelf lives, such as packaged goods, grains, and manufactured items, where ambient storage and transportation conditions suffice to maintain quality. Cold chain logistics is essential for perishable goods like pharmaceuticals, fresh produce, and frozen foods, requiring precise temperature control from storage to delivery to extend shelf life and prevent spoilage. Explore detailed comparisons and best practices to optimize both logistics types for your supply chain needs.

Storage Requirements

Dry logistics requires storage environments with controlled humidity and temperature to prevent damage to non-perishable goods, focusing primarily on warehouse efficiency and stacking methods. Cold chain logistics demands strict temperature-controlled storage facilities, often between -18degC and 8degC, to maintain product integrity for perishables like pharmaceuticals, frozen foods, and biological samples. Explore detailed storage solutions and best practices for optimizing both dry and cold chain logistics.

Source and External Links

What Is Dry LTL Shipping? - Dry logistics or dry LTL shipping refers to transporting goods in containers without temperature control, typically less than a full truckload, which is cheaper and more efficient than temperature-controlled shipping.

Dry LTL - Dry LTL means less-than-truckload shipments combined from multiple businesses, allowing small to midsize companies to save costs, simplify tracking, and leverage a large carrier network while shipping non-temperature-sensitive goods.

What is Dry Load and it's Importance - Dry load transport involves hauling goods by truck without liquids or refrigeration, playing a vital role in supply chains by providing flexible, reliable, and cost-effective delivery of non-perishable items.

dowidth.com

dowidth.com