Urban warehouses provide strategically located storage spaces within city limits, enabling faster delivery and reduced transportation costs for last-mile logistics. Cross-dock facilities streamline supply chain efficiency by minimizing storage time through immediate sorting and redistribution of goods, often serving as transit hubs. Discover more about how these logistics solutions optimize urban distribution and supply chain management.

Why it is important

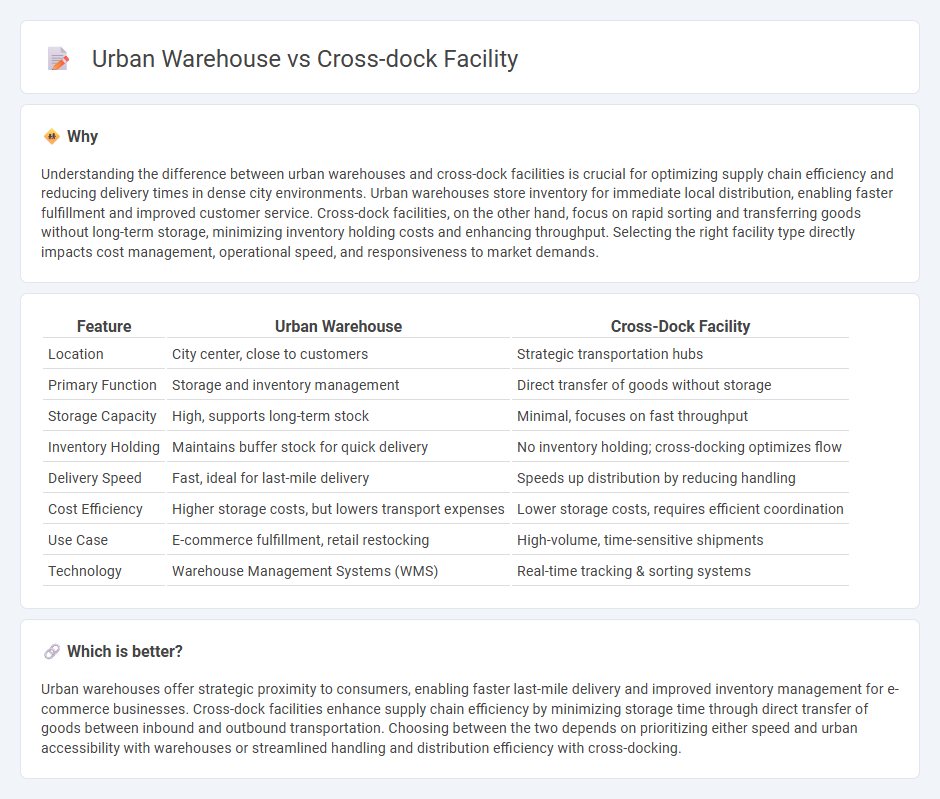

Understanding the difference between urban warehouses and cross-dock facilities is crucial for optimizing supply chain efficiency and reducing delivery times in dense city environments. Urban warehouses store inventory for immediate local distribution, enabling faster fulfillment and improved customer service. Cross-dock facilities, on the other hand, focus on rapid sorting and transferring goods without long-term storage, minimizing inventory holding costs and enhancing throughput. Selecting the right facility type directly impacts cost management, operational speed, and responsiveness to market demands.

Comparison Table

| Feature | Urban Warehouse | Cross-Dock Facility |

|---|---|---|

| Location | City center, close to customers | Strategic transportation hubs |

| Primary Function | Storage and inventory management | Direct transfer of goods without storage |

| Storage Capacity | High, supports long-term stock | Minimal, focuses on fast throughput |

| Inventory Holding | Maintains buffer stock for quick delivery | No inventory holding; cross-docking optimizes flow |

| Delivery Speed | Fast, ideal for last-mile delivery | Speeds up distribution by reducing handling |

| Cost Efficiency | Higher storage costs, but lowers transport expenses | Lower storage costs, requires efficient coordination |

| Use Case | E-commerce fulfillment, retail restocking | High-volume, time-sensitive shipments |

| Technology | Warehouse Management Systems (WMS) | Real-time tracking & sorting systems |

Which is better?

Urban warehouses offer strategic proximity to consumers, enabling faster last-mile delivery and improved inventory management for e-commerce businesses. Cross-dock facilities enhance supply chain efficiency by minimizing storage time through direct transfer of goods between inbound and outbound transportation. Choosing between the two depends on prioritizing either speed and urban accessibility with warehouses or streamlined handling and distribution efficiency with cross-docking.

Connection

Urban warehouses and cross-dock facilities are interconnected by their roles in streamlining last-mile logistics and reducing delivery times in densely populated areas. Urban warehouses store inventory close to end consumers, enabling faster order fulfillment, while cross-dock facilities facilitate the rapid transfer of goods between incoming and outgoing transportation without long-term storage. Together, they optimize the supply chain by minimizing inventory holding costs and improving the efficiency of distribution networks within metropolitan regions.

Key Terms

**Cross-dock Facility:**

A cross-dock facility streamlines supply chain efficiency by minimizing storage time through direct transfer of goods from inbound to outbound transportation, significantly reducing inventory holding costs. This facility excels in handling high-volume, time-sensitive shipments, making it essential for just-in-time delivery systems and perishable goods management. Discover more about how cross-dock operations optimize logistics performance and reduce delivery lead times.

Transshipment

Cross-dock facilities optimize transshipment by minimizing storage time, enabling rapid sorting and direct transfer of goods between inbound and outbound transportation. Urban warehouses support transshipment by providing strategic, flexible stock replenishment closer to end consumers, reducing delivery times and costs. Discover more about how each facility enhances supply chain efficiency through transshipment.

Minimal Storage

Cross-dock facilities prioritize minimal storage by rapidly transferring goods from inbound to outbound transportation, reducing inventory holding times to mere hours or less. Urban warehouses, while located close to consumers for quick delivery, typically hold inventory longer to manage demand fluctuations and enable same-day shipping. Explore how each model optimizes logistics efficiency and storage strategies to meet modern supply chain demands.

Source and External Links

Understanding cross-docking: A comprehensive guide - Maersk - A cross-dock facility is a specially designed warehouse where goods are transferred directly from inbound to outbound transportation with minimal or no storage time, focusing on efficient layout, dock door placement, scheduling, and automation to speed up handling and reduce errors.

How Does Cross Docking Work in Industrial Real Estate? - Cross-docking facilities feature opposite loading docks to enable rapid transfer of goods between arriving and departing trucks, eliminating long storage and helping distributors reduce costs and improve logistics flow.

What Is Cross-Docking? Definition, Types & Advantages - NetSuite - A cross-dock warehouse is a logistics center designed for quick unloading, sorting, and reloading of goods to outgoing vehicles, minimizing storage time and often arranged in I-shaped or other optimized layouts to support a seamless flow of inbound and outbound shipments.

dowidth.com

dowidth.com