Collaborative logistics leverages shared resources, data, and infrastructure among multiple supply chain partners to enhance efficiency, reduce costs, and improve service levels. Competitive logistics focuses on individual companies optimizing their own logistics operations to gain market advantage through faster delivery, lower expenses, and superior customer experience. Explore how combining collaboration and competition shapes the future of logistics strategies.

Why it is important

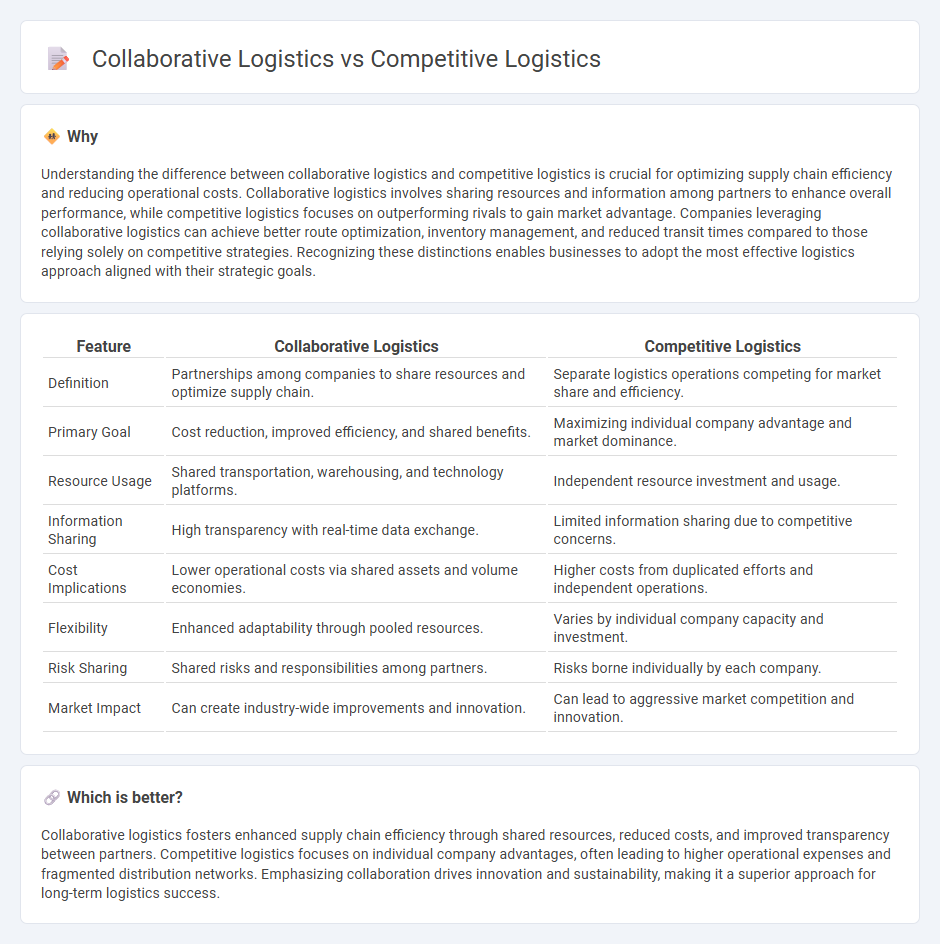

Understanding the difference between collaborative logistics and competitive logistics is crucial for optimizing supply chain efficiency and reducing operational costs. Collaborative logistics involves sharing resources and information among partners to enhance overall performance, while competitive logistics focuses on outperforming rivals to gain market advantage. Companies leveraging collaborative logistics can achieve better route optimization, inventory management, and reduced transit times compared to those relying solely on competitive strategies. Recognizing these distinctions enables businesses to adopt the most effective logistics approach aligned with their strategic goals.

Comparison Table

| Feature | Collaborative Logistics | Competitive Logistics |

|---|---|---|

| Definition | Partnerships among companies to share resources and optimize supply chain. | Separate logistics operations competing for market share and efficiency. |

| Primary Goal | Cost reduction, improved efficiency, and shared benefits. | Maximizing individual company advantage and market dominance. |

| Resource Usage | Shared transportation, warehousing, and technology platforms. | Independent resource investment and usage. |

| Information Sharing | High transparency with real-time data exchange. | Limited information sharing due to competitive concerns. |

| Cost Implications | Lower operational costs via shared assets and volume economies. | Higher costs from duplicated efforts and independent operations. |

| Flexibility | Enhanced adaptability through pooled resources. | Varies by individual company capacity and investment. |

| Risk Sharing | Shared risks and responsibilities among partners. | Risks borne individually by each company. |

| Market Impact | Can create industry-wide improvements and innovation. | Can lead to aggressive market competition and innovation. |

Which is better?

Collaborative logistics fosters enhanced supply chain efficiency through shared resources, reduced costs, and improved transparency between partners. Competitive logistics focuses on individual company advantages, often leading to higher operational expenses and fragmented distribution networks. Emphasizing collaboration drives innovation and sustainability, making it a superior approach for long-term logistics success.

Connection

Collaborative logistics enhances supply chain efficiency by facilitating information sharing, resource pooling, and joint transportation efforts among multiple stakeholders. Competitive logistics drives companies to optimize their own operations, focusing on cost reduction, speed, and service quality to outperform rivals. The connection between them lies in achieving a balance where collaboration improves overall network performance, while competition encourages innovation and operational excellence within individual logistics entities.

Key Terms

Cost Efficiency

Competitive logistics prioritizes cost efficiency by minimizing expenses through strict vendor negotiations, route optimization, and minimizing inventory holding costs. Collaborative logistics enhances cost efficiency by sharing resources, consolidating shipments, and leveraging collective bargaining power across multiple partners. Discover how businesses maximize savings by choosing between competitive and collaborative logistics strategies.

Information Sharing

Competitive logistics emphasizes limited information sharing to protect proprietary data and maintain a strategic advantage, often resulting in siloed operations. Collaborative logistics prioritizes transparent and real-time information exchange among stakeholders to enhance supply chain visibility, reduce costs, and improve service levels. Explore the benefits and challenges of both models to optimize your logistics strategy.

Supply Chain Integration

Competitive logistics emphasizes independent operations where firms optimize their own supply chain activities to gain market advantage, often resulting in siloed processes and limited information sharing. Collaborative logistics promotes integrated supply chain management by sharing resources, information, and coordinated planning among partners to enhance efficiency, reduce costs, and improve overall responsiveness. Explore in-depth strategies for balancing competition and collaboration in supply chain integration to advance your logistics performance.

Source and External Links

How to Stay Ahead in the Competitive World of Logistics - Maintaining a competitive edge in logistics requires innovation, adopting advanced technology, focusing on sustainability, and building strong partnerships to enhance efficiency and customer satisfaction.

Infographic: How to be competitive in the logistics industry - Competitiveness in logistics today hinges on embracing new technologies such as Big Data, Artificial Intelligence, and advanced analytics to optimize routes, improve customer service, and reduce costs in an increasingly complex and cost-sensitive environment.

The Power of Differentiation in the Competitive Logistics Industry - IFS - Differentiation in logistics involves unique value propositions, including specialized services and CRM system integration, which enhance customer experience, streamline sales, and boost operational efficiency to stand out in a competitive market.

dowidth.com

dowidth.com