Containerization streamlines global shipping by consolidating goods into standardized steel containers, enhancing security and reducing handling costs. Palletization organizes cargo into manageable units on pallets, enabling efficient loading and unloading within warehouses and transportation vehicles. Explore the key differences and benefits of containerization versus palletization in modern logistics.

Why it is important

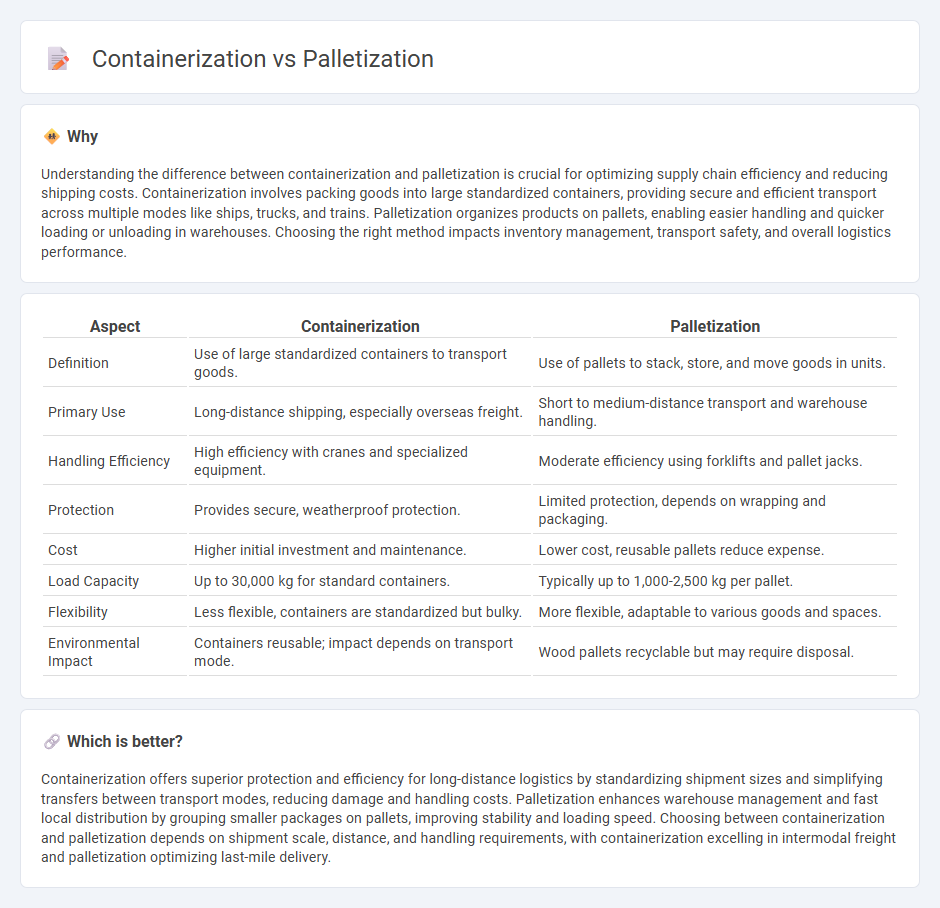

Understanding the difference between containerization and palletization is crucial for optimizing supply chain efficiency and reducing shipping costs. Containerization involves packing goods into large standardized containers, providing secure and efficient transport across multiple modes like ships, trucks, and trains. Palletization organizes products on pallets, enabling easier handling and quicker loading or unloading in warehouses. Choosing the right method impacts inventory management, transport safety, and overall logistics performance.

Comparison Table

| Aspect | Containerization | Palletization |

|---|---|---|

| Definition | Use of large standardized containers to transport goods. | Use of pallets to stack, store, and move goods in units. |

| Primary Use | Long-distance shipping, especially overseas freight. | Short to medium-distance transport and warehouse handling. |

| Handling Efficiency | High efficiency with cranes and specialized equipment. | Moderate efficiency using forklifts and pallet jacks. |

| Protection | Provides secure, weatherproof protection. | Limited protection, depends on wrapping and packaging. |

| Cost | Higher initial investment and maintenance. | Lower cost, reusable pallets reduce expense. |

| Load Capacity | Up to 30,000 kg for standard containers. | Typically up to 1,000-2,500 kg per pallet. |

| Flexibility | Less flexible, containers are standardized but bulky. | More flexible, adaptable to various goods and spaces. |

| Environmental Impact | Containers reusable; impact depends on transport mode. | Wood pallets recyclable but may require disposal. |

Which is better?

Containerization offers superior protection and efficiency for long-distance logistics by standardizing shipment sizes and simplifying transfers between transport modes, reducing damage and handling costs. Palletization enhances warehouse management and fast local distribution by grouping smaller packages on pallets, improving stability and loading speed. Choosing between containerization and palletization depends on shipment scale, distance, and handling requirements, with containerization excelling in intermodal freight and palletization optimizing last-mile delivery.

Connection

Containerization and palletization are connected through their roles in streamlining cargo handling and improving supply chain efficiency. Containerization standardizes large shipments into intermodal containers, while palletization organizes goods on pallets, facilitating easier loading and unloading within those containers. This synergy reduces transportation costs, minimizes product damage, and accelerates the movement of goods in logistics operations.

Key Terms

**Palletization:**

Palletization involves stacking goods on standardized platforms, called pallets, to facilitate easier handling, storage, and transportation, enhancing operational efficiency in warehouses and supply chains. It reduces labor costs, minimizes product damage, and accelerates loading and unloading times, making it a preferred choice for bulk and heavy goods. Explore more on how palletization optimizes logistics and inventory management.

Pallet

Palletization enhances warehouse efficiency by standardizing load sizes and enabling seamless forklift handling, which reduces shipping time and labor costs significantly. Pallets provide superior protection for goods by minimizing movement and damage during transit compared to individual packaging methods. Discover more about how palletization optimizes supply chain operations and improves overall logistics performance.

Unit Load

Palletization involves grouping goods on pallets to create a stable unit load for easier handling, storage, and transportation, while containerization uses standardized containers to consolidate multiple unit loads for global shipping efficiency and protection. Unit load optimization through palletization improves warehouse operations and reduces handling costs, whereas containerization enhances security and maximizes space utilization during transit. Discover more about how these methods impact supply chain logistics and operational efficiency.

Source and External Links

Types of Palletization - Maveneer - Palletization is the process of placing goods or shipping containers on a pallet for secure and efficient shipment, involving various stacking methods such as block, interlocking, brick, and pinwheel stacking and including manual palletizing which is cost-effective and flexible for different product types.

Palletization: Everything You Need to Know - Conger Industries - Palletization consolidates products on pallets for better stability, faster handling, and safer transport, with three main types: manual, semi-automated, and automated palletizing.

Palletize definition and meaning | FedEx Hong Kong SAR, China - Palletizing involves stacking items on pallets to optimize protection, reduce shipping costs, and improve inventory control, including steps like filling boxes fully, stacking uniformly, and securing with wrap.

dowidth.com

dowidth.com