Pick and pack and order consolidation are vital logistics strategies that enhance warehouse efficiency and reduce shipping costs. Pick and pack involves selecting individual items for multiple orders and packaging them separately, while order consolidation groups multiple orders into a single shipment to optimize delivery routes. Explore the key differences and benefits of each method to improve your supply chain operations.

Why it is important

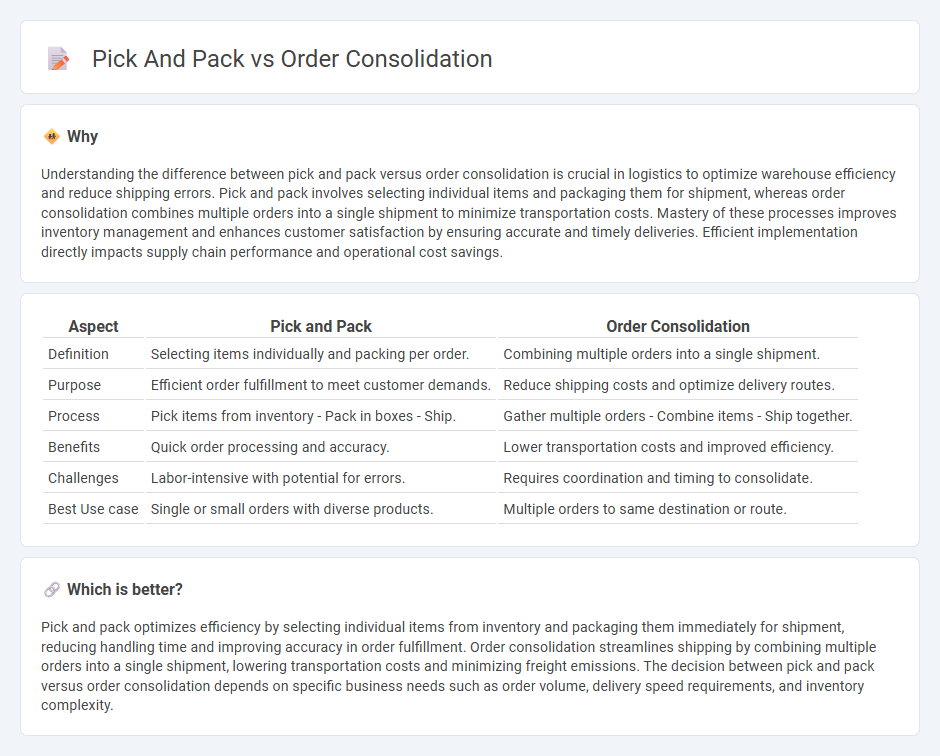

Understanding the difference between pick and pack versus order consolidation is crucial in logistics to optimize warehouse efficiency and reduce shipping errors. Pick and pack involves selecting individual items and packaging them for shipment, whereas order consolidation combines multiple orders into a single shipment to minimize transportation costs. Mastery of these processes improves inventory management and enhances customer satisfaction by ensuring accurate and timely deliveries. Efficient implementation directly impacts supply chain performance and operational cost savings.

Comparison Table

| Aspect | Pick and Pack | Order Consolidation |

|---|---|---|

| Definition | Selecting items individually and packing per order. | Combining multiple orders into a single shipment. |

| Purpose | Efficient order fulfillment to meet customer demands. | Reduce shipping costs and optimize delivery routes. |

| Process | Pick items from inventory - Pack in boxes - Ship. | Gather multiple orders - Combine items - Ship together. |

| Benefits | Quick order processing and accuracy. | Lower transportation costs and improved efficiency. |

| Challenges | Labor-intensive with potential for errors. | Requires coordination and timing to consolidate. |

| Best Use case | Single or small orders with diverse products. | Multiple orders to same destination or route. |

Which is better?

Pick and pack optimizes efficiency by selecting individual items from inventory and packaging them immediately for shipment, reducing handling time and improving accuracy in order fulfillment. Order consolidation streamlines shipping by combining multiple orders into a single shipment, lowering transportation costs and minimizing freight emissions. The decision between pick and pack versus order consolidation depends on specific business needs such as order volume, delivery speed requirements, and inventory complexity.

Connection

Pick and pack and order consolidation are integral processes in logistics that enhance efficiency by streamlining the handling of products. Pick and pack involves selecting items from inventory and packaging them for shipment, while order consolidation combines multiple orders or items into a single shipment to reduce transportation costs and improve delivery speed. Effective integration of these processes minimizes errors, optimizes warehouse operations, and lowers overall logistics expenses.

Key Terms

Order Consolidation:

Order consolidation significantly reduces shipping costs by combining multiple orders into a single shipment, optimizing logistics and inventory management. This process enhances delivery efficiency and minimizes packaging materials, contributing to sustainable operations. Explore how order consolidation can streamline your supply chain and boost customer satisfaction.

Shipment Optimization

Order consolidation reduces shipment costs by grouping multiple orders destined for the same location, enhancing delivery efficiency and minimizing transportation frequency. Pick and pack streamlines warehouse operations by selecting and packaging individual items per order, improving accuracy and speed in fulfillment. Explore more about optimizing your shipment strategy for cost-effective logistics management.

Freight Savings

Order consolidation reduces freight costs by combining multiple orders into a single shipment, minimizing transportation fees and optimizing load utilization. Pick and pack involves selecting individual items and packaging them separately, often resulting in higher shipping expenses due to multiple shipments and less efficient freight usage. Explore detailed strategies to enhance freight savings through effective consolidation methods.

Source and External Links

Order Consolidation: Definition, Steps, Best Practices - Artsyl - Order consolidation is a supply chain practice combining multiple smaller orders into one larger shipment to optimize efficiency, reduce costs, and improve logistics operations in ecommerce.

Order Consolidation Explained | Extensiv - This strategy merges multiple purchase orders with the same destination into a single shipment, lowering shipping costs, reducing carbon emissions, and enhancing customer satisfaction by avoiding multiple partial deliveries.

Order Consolidation, Staging and Buffering - AscentWL - Order consolidation physically aggregates all products of a multi-item order into one package for shipment, using automation tools like put walls or carousel systems for efficient staging and fulfillment, especially in omnichannel retail.

dowidth.com

dowidth.com