Pop-up warehousing offers flexible, short-term storage solutions ideal for seasonal demand spikes, while micro-fulfillment centers focus on high-efficiency, automated order processing near urban areas. These two logistics strategies address different aspects of inventory management and last-mile delivery challenges in e-commerce and retail. Explore how each option can optimize your supply chain and meet fluctuating consumer demands.

Why it is important

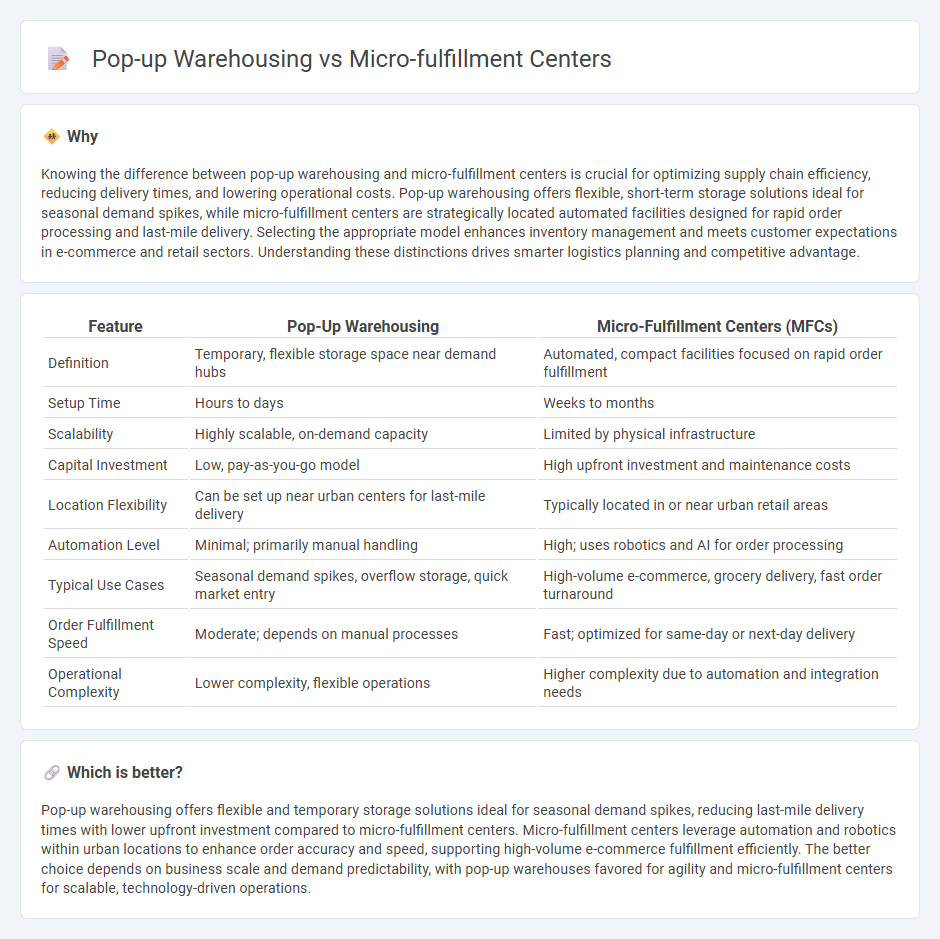

Knowing the difference between pop-up warehousing and micro-fulfillment centers is crucial for optimizing supply chain efficiency, reducing delivery times, and lowering operational costs. Pop-up warehousing offers flexible, short-term storage solutions ideal for seasonal demand spikes, while micro-fulfillment centers are strategically located automated facilities designed for rapid order processing and last-mile delivery. Selecting the appropriate model enhances inventory management and meets customer expectations in e-commerce and retail sectors. Understanding these distinctions drives smarter logistics planning and competitive advantage.

Comparison Table

| Feature | Pop-Up Warehousing | Micro-Fulfillment Centers (MFCs) |

|---|---|---|

| Definition | Temporary, flexible storage space near demand hubs | Automated, compact facilities focused on rapid order fulfillment |

| Setup Time | Hours to days | Weeks to months |

| Scalability | Highly scalable, on-demand capacity | Limited by physical infrastructure |

| Capital Investment | Low, pay-as-you-go model | High upfront investment and maintenance costs |

| Location Flexibility | Can be set up near urban centers for last-mile delivery | Typically located in or near urban retail areas |

| Automation Level | Minimal; primarily manual handling | High; uses robotics and AI for order processing |

| Typical Use Cases | Seasonal demand spikes, overflow storage, quick market entry | High-volume e-commerce, grocery delivery, fast order turnaround |

| Order Fulfillment Speed | Moderate; depends on manual processes | Fast; optimized for same-day or next-day delivery |

| Operational Complexity | Lower complexity, flexible operations | Higher complexity due to automation and integration needs |

Which is better?

Pop-up warehousing offers flexible and temporary storage solutions ideal for seasonal demand spikes, reducing last-mile delivery times with lower upfront investment compared to micro-fulfillment centers. Micro-fulfillment centers leverage automation and robotics within urban locations to enhance order accuracy and speed, supporting high-volume e-commerce fulfillment efficiently. The better choice depends on business scale and demand predictability, with pop-up warehouses favored for agility and micro-fulfillment centers for scalable, technology-driven operations.

Connection

Pop-up warehousing and micro-fulfillment centers both enhance supply chain efficiency by providing flexible, scalable storage solutions near urban demand hubs. Pop-up warehousing temporarily utilizes underused spaces to handle seasonal or fluctuating inventory needs, while micro-fulfillment centers offer automated, localized order processing to expedite last-mile delivery. Together, they optimize inventory management and reduce transportation costs in omnichannel logistics strategies.

Key Terms

Automation

Micro-fulfillment centers leverage advanced automation technologies such as robotics and AI-driven sorting systems to accelerate order processing and maximize space efficiency in urban areas. Pop-up warehousing, although flexible and temporary, often relies on manual labor and basic automation, limiting scalability and speed compared to micro-fulfillment solutions. Explore how automation shapes the future of agile supply chain strategies to enhance your logistics operations.

Scalability

Micro-fulfillment centers offer scalable solutions by automating order processing within urban areas, enabling retailers to quickly expand capacity to meet growing e-commerce demand. Pop-up warehousing provides flexible, short-term spaces ideal for seasonal spikes or testing new markets without long-term commitments, though scalability depends on available local infrastructure. Explore detailed comparisons to understand which model suits your business growth strategy best.

Last-mile delivery

Micro-fulfillment centers enhance last-mile delivery by positioning automated, compact warehouses close to urban consumers, reducing delivery times and fulfilling online orders rapidly. Pop-up warehousing offers flexible, temporary storage solutions that adapt to seasonal demand spikes, improving inventory availability near high-demand areas without long-term commitments. Explore how these innovative fulfillment strategies can transform your last-mile delivery efficiency.

Source and External Links

Micro-Fulfillment Explained: Key Benefits and Strategies for Ecommerce Success - Micro-fulfillment centers are small, highly efficient warehouses (3,000 to 10,000 sq ft) located in urban areas to hold high-demand products for rapid shipping, enabling faster delivery, reduced costs, and improved supply chain efficiency.

What Are Micro Fulfillment Centers? - City National Bank - MFCs are compact warehouses that store units of fast-selling items, often operated by robots or humans, turning inventory 8-10 times per year versus 1-2 times in traditional warehouses, helping retailers meet tight customer expectations.

Walgreens to increase stores serviced by micro-fulfillment centers - Walgreens operates 11 micro-fulfillment centers servicing over 4,500 stores and plans to expand to 6,000 stores while improving operational efficiency and cost-effectiveness of these automated centers.

dowidth.com

dowidth.com