Green corridors streamline sustainable transportation routes to minimize carbon emissions and enhance environmental efficiency. Cold chains maintain temperature-controlled supply networks essential for preserving perishable goods such as pharmaceuticals and fresh produce. Explore the distinctions and benefits of green corridors versus cold chain logistics to optimize your supply strategies.

Why it is important

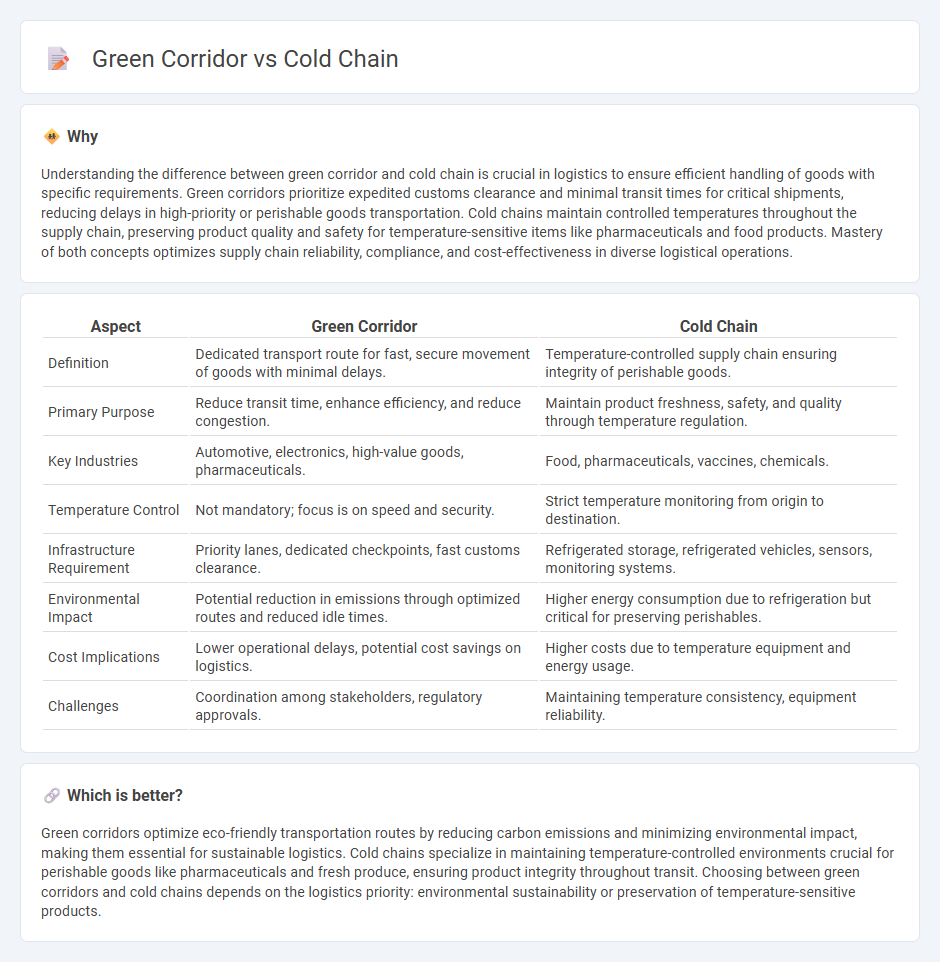

Understanding the difference between green corridor and cold chain is crucial in logistics to ensure efficient handling of goods with specific requirements. Green corridors prioritize expedited customs clearance and minimal transit times for critical shipments, reducing delays in high-priority or perishable goods transportation. Cold chains maintain controlled temperatures throughout the supply chain, preserving product quality and safety for temperature-sensitive items like pharmaceuticals and food products. Mastery of both concepts optimizes supply chain reliability, compliance, and cost-effectiveness in diverse logistical operations.

Comparison Table

| Aspect | Green Corridor | Cold Chain |

|---|---|---|

| Definition | Dedicated transport route for fast, secure movement of goods with minimal delays. | Temperature-controlled supply chain ensuring integrity of perishable goods. |

| Primary Purpose | Reduce transit time, enhance efficiency, and reduce congestion. | Maintain product freshness, safety, and quality through temperature regulation. |

| Key Industries | Automotive, electronics, high-value goods, pharmaceuticals. | Food, pharmaceuticals, vaccines, chemicals. |

| Temperature Control | Not mandatory; focus is on speed and security. | Strict temperature monitoring from origin to destination. |

| Infrastructure Requirement | Priority lanes, dedicated checkpoints, fast customs clearance. | Refrigerated storage, refrigerated vehicles, sensors, monitoring systems. |

| Environmental Impact | Potential reduction in emissions through optimized routes and reduced idle times. | Higher energy consumption due to refrigeration but critical for preserving perishables. |

| Cost Implications | Lower operational delays, potential cost savings on logistics. | Higher costs due to temperature equipment and energy usage. |

| Challenges | Coordination among stakeholders, regulatory approvals. | Maintaining temperature consistency, equipment reliability. |

Which is better?

Green corridors optimize eco-friendly transportation routes by reducing carbon emissions and minimizing environmental impact, making them essential for sustainable logistics. Cold chains specialize in maintaining temperature-controlled environments crucial for perishable goods like pharmaceuticals and fresh produce, ensuring product integrity throughout transit. Choosing between green corridors and cold chains depends on the logistics priority: environmental sustainability or preservation of temperature-sensitive products.

Connection

Green corridors in logistics enhance sustainability by reducing carbon emissions through optimized transportation routes, while cold chains ensure the integrity of temperature-sensitive goods during transit. Integrating cold chain systems within green corridors promotes energy-efficient refrigerated transport, minimizing environmental impact and preserving product quality. This synergy supports eco-friendly supply chains in sectors like pharmaceuticals, food, and agriculture.

Key Terms

**Cold Chain:**

Cold chain logistics ensures the temperature-controlled supply and storage of perishable goods, pharmaceuticals, and vaccines, maintaining product integrity from origin to destination. Key components include refrigeration units, insulated packaging, and real-time temperature monitoring systems to prevent spoilage and extend shelf life. Discover more about the critical technologies and processes that optimize cold chain efficiency and sustainability.

Temperature Control

Cold chain logistics ensures strict temperature control by using refrigerated vehicles, insulated packaging, and real-time monitoring to maintain the integrity of perishable goods from origin to destination. Green corridors optimize transport routes to minimize transit time and environmental impact, often integrating temperature control technologies to preserve sensitive products during expedited delivery. Explore detailed strategies and technological innovations in temperature control by examining the distinctive approaches of cold chain and green corridor logistics.

Perishable Goods

Cold chain logistics maintains strict temperature control throughout the supply chain, ensuring the freshness and safety of perishable goods such as fruits, vegetables, dairy, and pharmaceuticals. Green corridors prioritize speed and dedicated transport routes, minimizing transit time and reducing spoilage risks for time-sensitive products. Explore the benefits and applications of these strategies to optimize perishable goods delivery efficiency.

Source and External Links

B.9 - The Cold Chain and its Logistics - The cold chain is a temperature-controlled supply process involving cooling systems, cold storage, transport, and processing to preserve perishable goods like food, which supports global trade and healthy diets.

Cold Chain Definition | UPS Supply Chain Solutions - United States - Cold chain is a continuous temperature-controlled supply chain that maintains refrigeration across manufacturing, transport, warehousing, and delivery to preserve perishable foods, drugs, and chemicals.

The Cold, Hard Facts About Cold Chain Logistics - Art of Procurement - The cold chain concept dates back to 1908 for meat storage and transport and has evolved to include mechanical refrigeration and insulated containers with dry ice to ensure consistent low temperatures in logistics.

dowidth.com

dowidth.com