Predictive fleet maintenance leverages real-time data and advanced analytics to anticipate vehicle repairs, reducing downtime and operational costs. Demand forecasting analyzes market trends and historical data to optimize inventory levels and resource allocation within the supply chain. Explore how integrating these strategies enhances efficiency and profitability in logistics management.

Why it is important

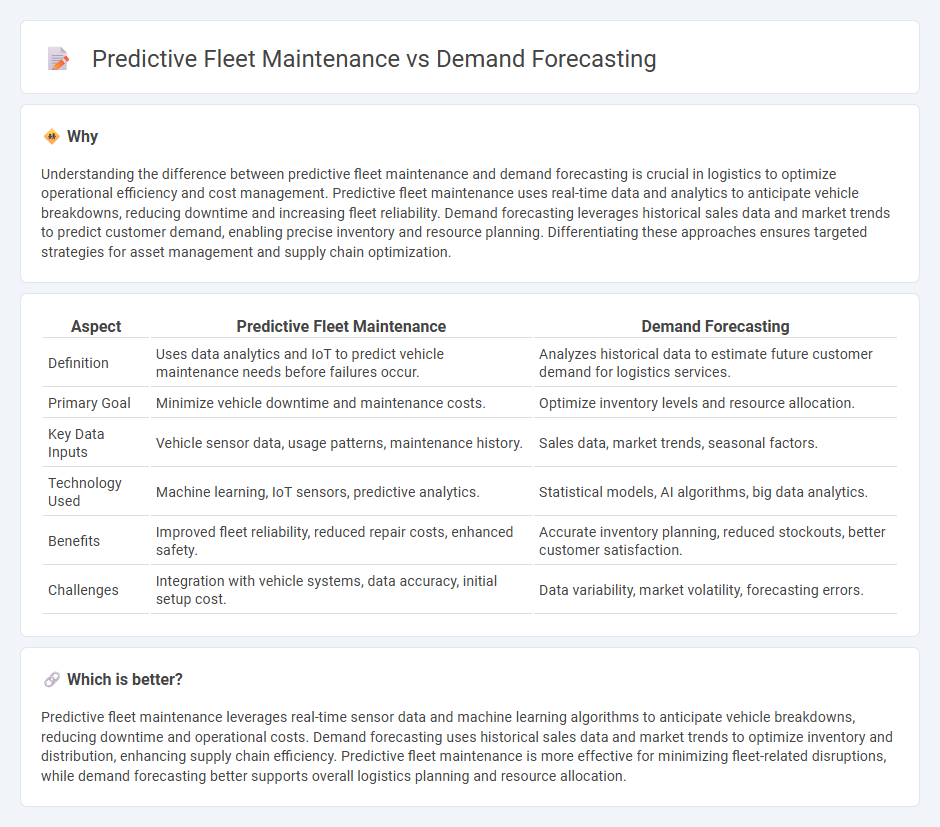

Understanding the difference between predictive fleet maintenance and demand forecasting is crucial in logistics to optimize operational efficiency and cost management. Predictive fleet maintenance uses real-time data and analytics to anticipate vehicle breakdowns, reducing downtime and increasing fleet reliability. Demand forecasting leverages historical sales data and market trends to predict customer demand, enabling precise inventory and resource planning. Differentiating these approaches ensures targeted strategies for asset management and supply chain optimization.

Comparison Table

| Aspect | Predictive Fleet Maintenance | Demand Forecasting |

|---|---|---|

| Definition | Uses data analytics and IoT to predict vehicle maintenance needs before failures occur. | Analyzes historical data to estimate future customer demand for logistics services. |

| Primary Goal | Minimize vehicle downtime and maintenance costs. | Optimize inventory levels and resource allocation. |

| Key Data Inputs | Vehicle sensor data, usage patterns, maintenance history. | Sales data, market trends, seasonal factors. |

| Technology Used | Machine learning, IoT sensors, predictive analytics. | Statistical models, AI algorithms, big data analytics. |

| Benefits | Improved fleet reliability, reduced repair costs, enhanced safety. | Accurate inventory planning, reduced stockouts, better customer satisfaction. |

| Challenges | Integration with vehicle systems, data accuracy, initial setup cost. | Data variability, market volatility, forecasting errors. |

Which is better?

Predictive fleet maintenance leverages real-time sensor data and machine learning algorithms to anticipate vehicle breakdowns, reducing downtime and operational costs. Demand forecasting uses historical sales data and market trends to optimize inventory and distribution, enhancing supply chain efficiency. Predictive fleet maintenance is more effective for minimizing fleet-related disruptions, while demand forecasting better supports overall logistics planning and resource allocation.

Connection

Predictive fleet maintenance leverages real-time data and machine learning algorithms to anticipate vehicle breakdowns, minimizing downtime and operational disruptions. Demand forecasting analyzes historical and market data to predict transportation needs, enabling optimized fleet allocation and route planning. Integrating these approaches ensures efficient resource management, reduces costs, and improves service reliability in logistics operations.

Key Terms

**Demand Forecasting:**

Demand forecasting involves analyzing historical sales data, market trends, and consumer behavior to predict future product demand accurately. It enables businesses to optimize inventory levels, reduce stockouts, and improve supply chain efficiency. Discover more about how demand forecasting drives strategic decision-making and operational excellence.

Historical Sales Data

Historical sales data plays a crucial role in demand forecasting by enabling accurate prediction of future product needs through trend and seasonality analysis. In predictive fleet maintenance, historical sales data is less relevant; instead, maintenance logs and sensor data are prioritized to predict equipment failures. Explore how integrating diverse data sources enhances operational efficiency and cost savings.

Seasonality Analysis

Demand forecasting leverages seasonality analysis to predict fluctuations in consumer demand by identifying patterns related to specific time periods, such as holidays or weather changes. Predictive fleet maintenance applies seasonality insights to anticipate vehicle wear and tear influenced by seasonal conditions, optimizing maintenance schedules and reducing downtime. Explore how integrating seasonality analysis enhances accuracy in both demand forecasting and predictive fleet maintenance strategies.

Source and External Links

Types of Demand Forecast - GeeksforGeeks - Demand forecasting uses predictive analysis of historical data to project future customer demand and helps businesses optimize inventory, production, and pricing decisions by anticipating future demand patterns through various methods like active forecasting, market research, and econometrics.

Demand Forecasting Guide: Definition, Types, Methods, Examples - Demand forecasting estimates future product demand using methods such as trend projection, market research, and sales force composite to guide inventory and production decisions in businesses.

Demand forecasting - Wikipedia - Demand forecasting predicts the quantity of goods and services consumers or businesses will require in the future, using qualitative methods like expert opinion when data is limited, and quantitative methods analyzing available data, playing a critical role in supply chain optimization and business planning.

dowidth.com

dowidth.com