Urban warehouses are strategically located near city centers to facilitate faster last-mile delivery and reduce transportation costs. Micro-fulfillment centers utilize advanced automation in smaller spaces within urban areas to accelerate order processing and boost efficiency for e-commerce fulfillment. Explore how these two logistics models transform urban supply chain operations and meet rising consumer demands.

Why it is important

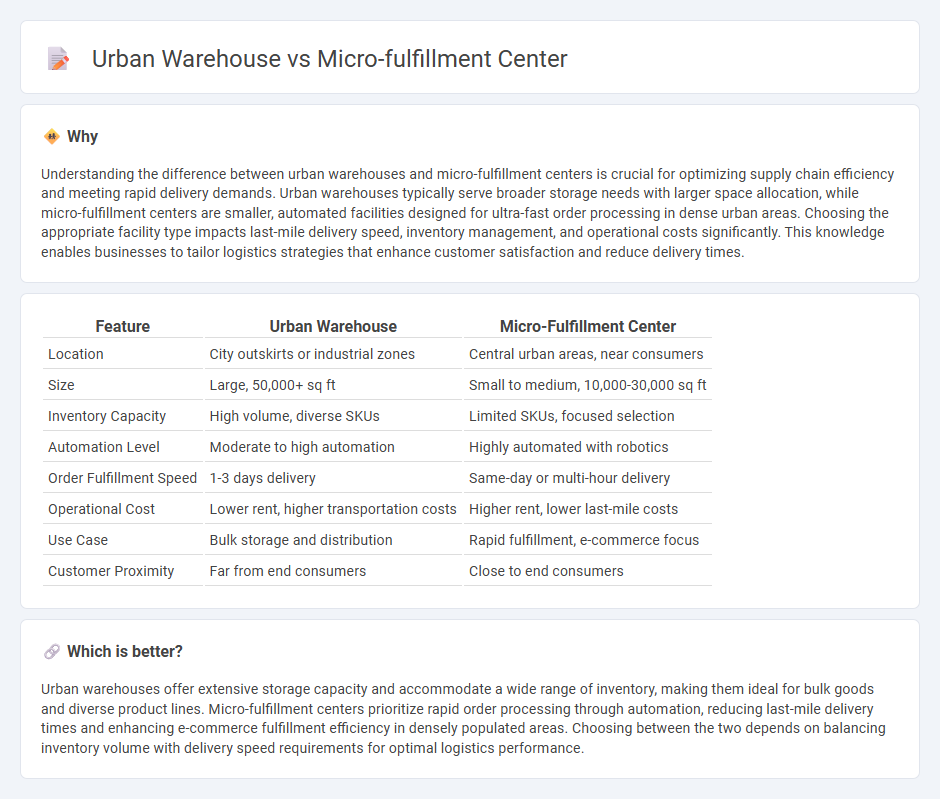

Understanding the difference between urban warehouses and micro-fulfillment centers is crucial for optimizing supply chain efficiency and meeting rapid delivery demands. Urban warehouses typically serve broader storage needs with larger space allocation, while micro-fulfillment centers are smaller, automated facilities designed for ultra-fast order processing in dense urban areas. Choosing the appropriate facility type impacts last-mile delivery speed, inventory management, and operational costs significantly. This knowledge enables businesses to tailor logistics strategies that enhance customer satisfaction and reduce delivery times.

Comparison Table

| Feature | Urban Warehouse | Micro-Fulfillment Center |

|---|---|---|

| Location | City outskirts or industrial zones | Central urban areas, near consumers |

| Size | Large, 50,000+ sq ft | Small to medium, 10,000-30,000 sq ft |

| Inventory Capacity | High volume, diverse SKUs | Limited SKUs, focused selection |

| Automation Level | Moderate to high automation | Highly automated with robotics |

| Order Fulfillment Speed | 1-3 days delivery | Same-day or multi-hour delivery |

| Operational Cost | Lower rent, higher transportation costs | Higher rent, lower last-mile costs |

| Use Case | Bulk storage and distribution | Rapid fulfillment, e-commerce focus |

| Customer Proximity | Far from end consumers | Close to end consumers |

Which is better?

Urban warehouses offer extensive storage capacity and accommodate a wide range of inventory, making them ideal for bulk goods and diverse product lines. Micro-fulfillment centers prioritize rapid order processing through automation, reducing last-mile delivery times and enhancing e-commerce fulfillment efficiency in densely populated areas. Choosing between the two depends on balancing inventory volume with delivery speed requirements for optimal logistics performance.

Connection

Urban warehouses and micro-fulfillment centers are interconnected by their shared goal of accelerating last-mile delivery within dense metropolitan areas, reducing transit times and lowering transportation costs. Urban warehouses act as central hubs for inventory storage closer to customers, while micro-fulfillment centers utilize automation and robotics to efficiently process and dispatch smaller orders in limited spaces. Together, they optimize supply chain efficiency by enabling rapid order fulfillment and improving customer satisfaction in urban logistics networks.

Key Terms

Proximity to End Customer

Micro-fulfillment centers are strategically located near dense urban populations to ensure rapid delivery speeds and reduce last-mile logistics costs. Urban warehouses, while also situated within city limits, tend to function as larger inventory hubs that serve multiple micro-fulfillment sites or retail outlets but may not offer the same level of immediacy in customer proximity. Explore more about how location influences efficiency in last-mile delivery.

Automation Level

Micro-fulfillment centers utilize advanced automation technologies such as robotics and AI-driven inventory systems to optimize rapid order fulfillment in dense urban areas. Urban warehouses tend to have lower automation levels, focusing more on manual processes to handle a broader range of inventory and customer needs. Explore our detailed analysis for a deeper understanding of how automation impacts efficiency in these fulfillment models.

Order Fulfillment Speed

Micro-fulfillment centers leverage automated technologies and strategic placements within urban areas to drastically reduce order fulfillment times, often achieving same-day or even hourly deliveries. Urban warehouses, while closer to customers than traditional distribution centers, typically rely on manual processes that can slow down order processing speed. Explore how each model impacts your logistics efficiency and customer satisfaction levels.

Source and External Links

Micro-Fulfillment Explained: Key Benefits and Strategies for Ecommerce Success - Micro-fulfillment centers (MFCs) are small, highly efficient warehouses (3,000 to 10,000 square feet) located close to urban consumers, storing up to 15,000 items, to enable rapid delivery and reduce last-mile costs while enhancing supply chain efficiency and customer satisfaction.

What Are Micro Fulfillment Centers? - City National Bank - MFCs are compact warehouses focused on fast-moving products, typically smaller than traditional warehouses, using technology and sometimes robotics to pick and ship orders quickly, largely adopted by grocery and retail sectors, with high inventory turnover rates.

Micro fulfillment center: How it helps retailers speed up fulfillment - Micro-fulfillment centers are small-scale facilities located in or near urban areas to accelerate order fulfillment through technology and automation; they can be standalone units or integrated into existing retail locations, storing only short-term inventory for rapid delivery or pickup.

dowidth.com

dowidth.com