Cold chain logistics involves the temperature-controlled transportation of perishable goods such as pharmaceuticals and food products to maintain quality and safety. Project cargo logistics focuses on the complex planning and handling of oversized or heavy shipments that require specialized equipment and coordination. Discover the key differences and benefits of each logistics type to optimize your supply chain strategy.

Why it is important

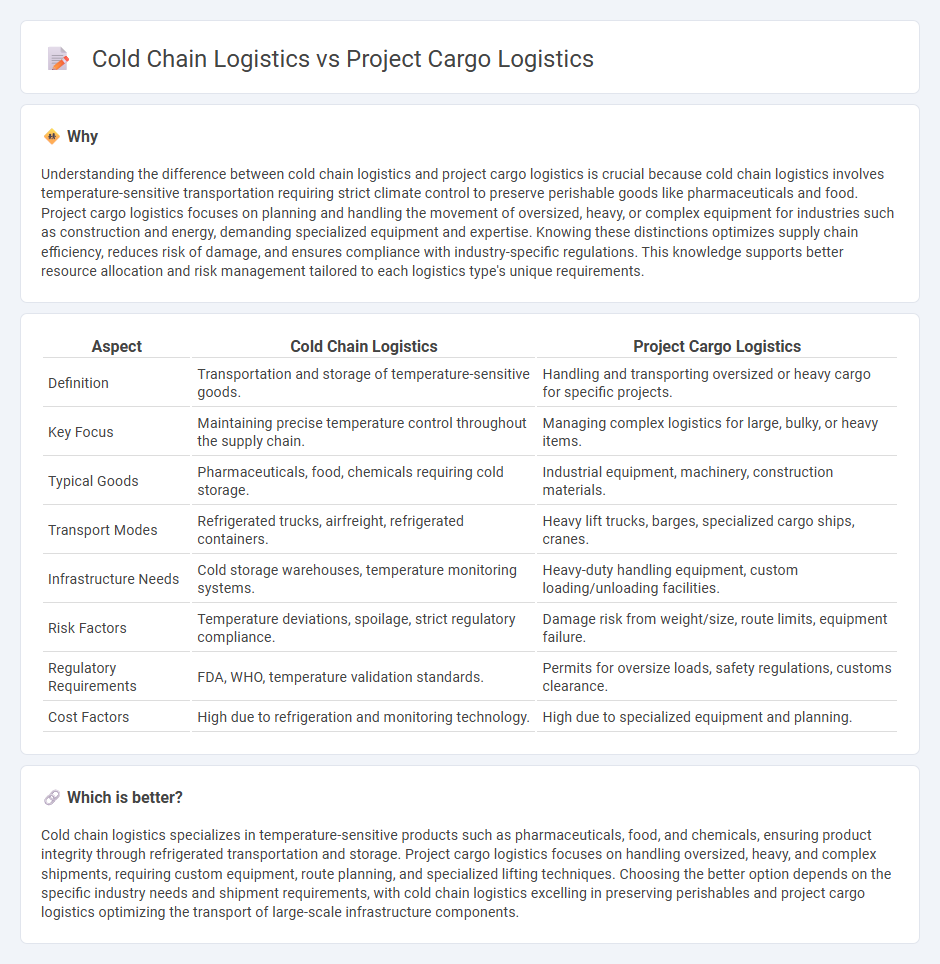

Understanding the difference between cold chain logistics and project cargo logistics is crucial because cold chain logistics involves temperature-sensitive transportation requiring strict climate control to preserve perishable goods like pharmaceuticals and food. Project cargo logistics focuses on planning and handling the movement of oversized, heavy, or complex equipment for industries such as construction and energy, demanding specialized equipment and expertise. Knowing these distinctions optimizes supply chain efficiency, reduces risk of damage, and ensures compliance with industry-specific regulations. This knowledge supports better resource allocation and risk management tailored to each logistics type's unique requirements.

Comparison Table

| Aspect | Cold Chain Logistics | Project Cargo Logistics |

|---|---|---|

| Definition | Transportation and storage of temperature-sensitive goods. | Handling and transporting oversized or heavy cargo for specific projects. |

| Key Focus | Maintaining precise temperature control throughout the supply chain. | Managing complex logistics for large, bulky, or heavy items. |

| Typical Goods | Pharmaceuticals, food, chemicals requiring cold storage. | Industrial equipment, machinery, construction materials. |

| Transport Modes | Refrigerated trucks, airfreight, refrigerated containers. | Heavy lift trucks, barges, specialized cargo ships, cranes. |

| Infrastructure Needs | Cold storage warehouses, temperature monitoring systems. | Heavy-duty handling equipment, custom loading/unloading facilities. |

| Risk Factors | Temperature deviations, spoilage, strict regulatory compliance. | Damage risk from weight/size, route limits, equipment failure. |

| Regulatory Requirements | FDA, WHO, temperature validation standards. | Permits for oversize loads, safety regulations, customs clearance. |

| Cost Factors | High due to refrigeration and monitoring technology. | High due to specialized equipment and planning. |

Which is better?

Cold chain logistics specializes in temperature-sensitive products such as pharmaceuticals, food, and chemicals, ensuring product integrity through refrigerated transportation and storage. Project cargo logistics focuses on handling oversized, heavy, and complex shipments, requiring custom equipment, route planning, and specialized lifting techniques. Choosing the better option depends on the specific industry needs and shipment requirements, with cold chain logistics excelling in preserving perishables and project cargo logistics optimizing the transport of large-scale infrastructure components.

Connection

Cold chain logistics ensures temperature-sensitive goods remain within controlled environments during transportation, while project cargo logistics manages the shipment of oversized or heavy equipment. Both logistics types require meticulous planning, specialized handling, and real-time monitoring to maintain product integrity and ensure timely delivery. Integration of cold chain protocols within project cargo logistics is essential for transporting large-scale temperature-sensitive materials like pharmaceuticals, perishables, and chemicals.

Key Terms

**Project Cargo Logistics:**

Project cargo logistics involves the transportation of oversized, heavy, or complex equipment requiring specialized handling, routing, and equipment coordination. It demands meticulous planning, risk assessment, and multimodal solutions to ensure safe and timely delivery of goods such as industrial machinery, construction components, and wind turbine blades. Discover more about the critical processes and specialized services in project cargo logistics.

Heavy Lift

Project cargo logistics specializes in transporting oversized, heavy lift equipment such as industrial machinery, power plant components, and construction materials, requiring specialized handling, rigging, and transporting solutions. Cold chain logistics focuses on temperature-sensitive goods like pharmaceuticals, perishable foods, and chemicals, necessitating insulated containers, refrigeration units, and continuous temperature monitoring to maintain product integrity. Explore detailed logistics strategies to understand the unique challenges and requirements of heavy lift operations within both sectors.

Route Survey

Project cargo logistics involves detailed route surveys to assess infrastructure capabilities such as bridge load limits, road width, and clearance heights essential for transporting oversized or heavy equipment. Cold chain logistics route surveys prioritize maintaining temperature-controlled environments, emphasizing access to reliable refrigeration facilities and minimizing transit times to preserve perishable goods. Explore further to understand the specific methodologies and technologies used in route surveys for each logistics type.

Source and External Links

What is Project Cargo Logistics - Project cargo logistics involves the transportation of large, heavy, oversized, high-value, or complex equipment using specialized handling and transport modes such as road, rail, sea, or air to ensure safe and efficient delivery under strict planning and safety conditions.

What is Project Cargo? - Freight Right - Project cargo logistics is a complex transport service for oversized or high-value goods that require detailed coordination to meet tight timelines, safety rules, and may involve multi-modal shipping plus special accommodations like police escorts or road surveys.

Project Cargo - Heavy Freight - Expeditors - Project cargo logistics providers offer customized, integrated project management and transport solutions focusing on oversized and heavy-lift freight, including route planning, risk assessments, and supervision to handle challenges related to size, weight, and complexity.

dowidth.com

dowidth.com