Silent delivery minimizes noise pollution and disturbances in urban logistics by utilizing electric vehicles and off-peak hours, enhancing customer satisfaction and compliance with local regulations. Just-in-time (JIT) delivery focuses on inventory efficiency by synchronizing shipments to arrive exactly when needed, reducing storage costs and waste. Explore the benefits and challenges of silent delivery versus just-in-time delivery to optimize your supply chain performance.

Why it is important

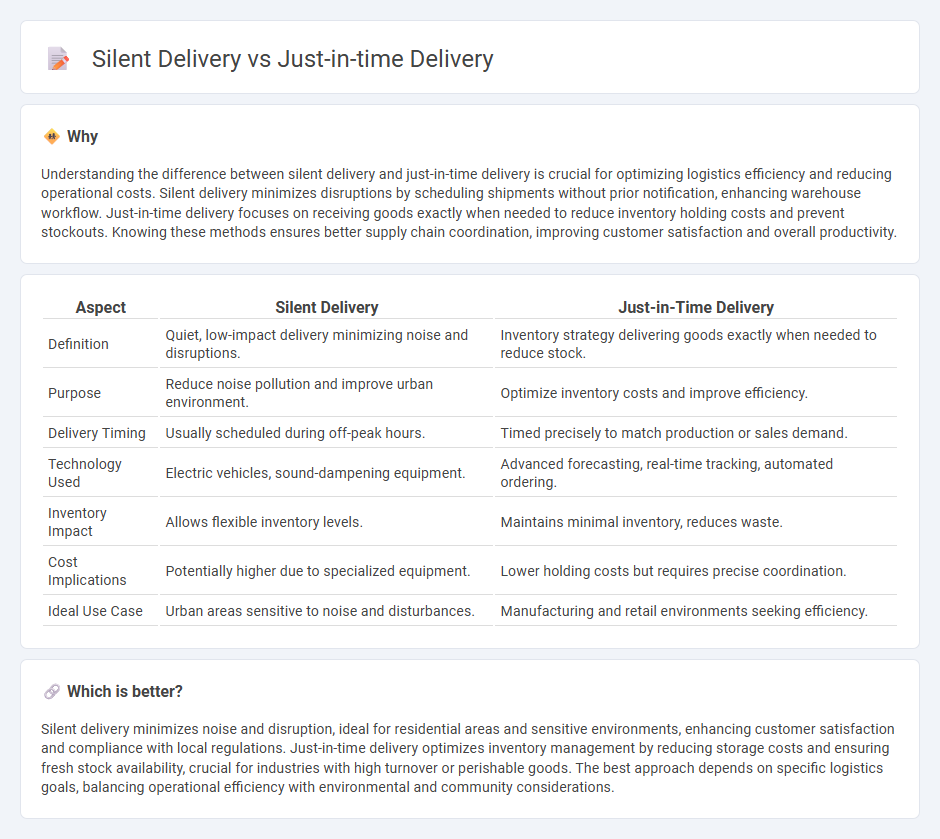

Understanding the difference between silent delivery and just-in-time delivery is crucial for optimizing logistics efficiency and reducing operational costs. Silent delivery minimizes disruptions by scheduling shipments without prior notification, enhancing warehouse workflow. Just-in-time delivery focuses on receiving goods exactly when needed to reduce inventory holding costs and prevent stockouts. Knowing these methods ensures better supply chain coordination, improving customer satisfaction and overall productivity.

Comparison Table

| Aspect | Silent Delivery | Just-in-Time Delivery |

|---|---|---|

| Definition | Quiet, low-impact delivery minimizing noise and disruptions. | Inventory strategy delivering goods exactly when needed to reduce stock. |

| Purpose | Reduce noise pollution and improve urban environment. | Optimize inventory costs and improve efficiency. |

| Delivery Timing | Usually scheduled during off-peak hours. | Timed precisely to match production or sales demand. |

| Technology Used | Electric vehicles, sound-dampening equipment. | Advanced forecasting, real-time tracking, automated ordering. |

| Inventory Impact | Allows flexible inventory levels. | Maintains minimal inventory, reduces waste. |

| Cost Implications | Potentially higher due to specialized equipment. | Lower holding costs but requires precise coordination. |

| Ideal Use Case | Urban areas sensitive to noise and disturbances. | Manufacturing and retail environments seeking efficiency. |

Which is better?

Silent delivery minimizes noise and disruption, ideal for residential areas and sensitive environments, enhancing customer satisfaction and compliance with local regulations. Just-in-time delivery optimizes inventory management by reducing storage costs and ensuring fresh stock availability, crucial for industries with high turnover or perishable goods. The best approach depends on specific logistics goals, balancing operational efficiency with environmental and community considerations.

Connection

Silent delivery enhances just-in-time (JIT) delivery by minimizing noise disruptions during off-hour shipments, facilitating smoother and more efficient inventory management. This method supports JIT's goal of reducing storage costs and improving supply chain responsiveness by ensuring timely, quiet arrivals that prevent workplace disturbances. Implementing silent delivery techniques streamlines operations, enabling businesses to maintain lean inventories and meet production schedules precisely.

Key Terms

**Just-in-Time Delivery:**

Just-in-Time Delivery optimizes inventory management by ensuring materials arrive precisely when needed, reducing storage costs and minimizing waste. This approach enhances production efficiency and responsiveness to market demands, making it ideal for lean manufacturing systems. Explore more to understand how Just-in-Time Delivery can transform supply chain operations.

Inventory Minimization

Just-in-time delivery significantly reduces inventory holding costs by synchronizing supply arrival with production schedules, minimizing stock levels and storage space requirements. Silent delivery prioritizes discreet, contactless shipment to maintain operational efficiency without disrupting the inventory flow. Discover how these contrasting strategies optimize inventory management and operational agility.

Supplier Coordination

Just-in-time delivery maximizes supplier coordination by ensuring materials arrive precisely when needed, reducing inventory costs and enhancing production flow efficiency. Silent delivery emphasizes discreet supplier collaboration to minimize disruptions and maintain operational security during the supply chain process. Explore detailed strategies to optimize supplier coordination in both delivery methods for enhanced supply chain performance.

Source and External Links

Just in Time Delivery: What is it, and How Does it Affect Supply ... - Just-in-time delivery is a logistics approach where goods are produced or completed so that minimal inventory satisfies demand, ensuring delivery happens exactly when consumers want, reducing excess inventory and costs.

Just In Time (JIT) Delivery: The Ultimate Guide - Elite EXTRA - JIT delivery is an inventory strategy focused on producing and delivering products on demand to reduce inventory costs, increase efficiency, and respond quickly to customer needs by moving inventory as needed without storing excess stock.

What is JIT Delivery? - AGI Global Logistics - Just-in-Time delivery is a strategy to minimize storage costs and waste by delivering goods exactly when needed, using a pull-based system aligned with actual demand rather than forecasts, often supported by lean manufacturing and Kanban inventory management.

dowidth.com

dowidth.com