Supply chain control towers provide centralized visibility and real-time monitoring across the entire logistics network, enabling proactive decision-making and rapid response to disruptions. Demand planning focuses on forecasting customer demand to optimize inventory levels and ensure product availability while minimizing costs. Explore how integrating control towers with demand planning can enhance supply chain efficiency and resilience.

Why it is important

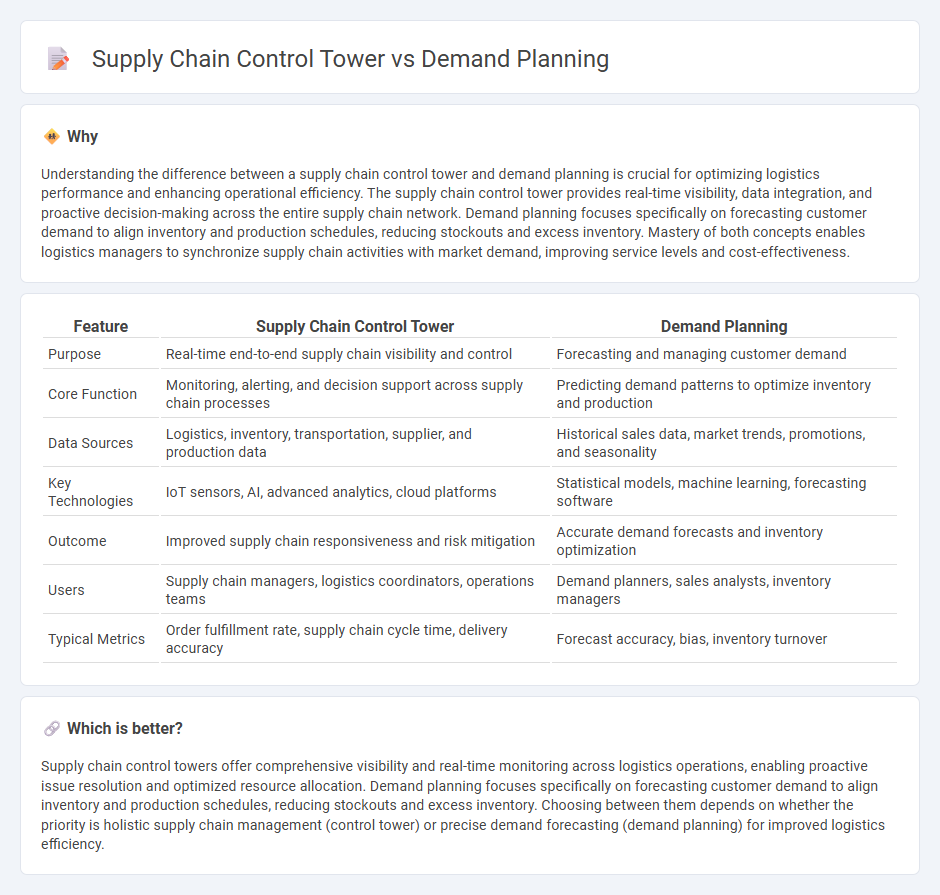

Understanding the difference between a supply chain control tower and demand planning is crucial for optimizing logistics performance and enhancing operational efficiency. The supply chain control tower provides real-time visibility, data integration, and proactive decision-making across the entire supply chain network. Demand planning focuses specifically on forecasting customer demand to align inventory and production schedules, reducing stockouts and excess inventory. Mastery of both concepts enables logistics managers to synchronize supply chain activities with market demand, improving service levels and cost-effectiveness.

Comparison Table

| Feature | Supply Chain Control Tower | Demand Planning |

|---|---|---|

| Purpose | Real-time end-to-end supply chain visibility and control | Forecasting and managing customer demand |

| Core Function | Monitoring, alerting, and decision support across supply chain processes | Predicting demand patterns to optimize inventory and production |

| Data Sources | Logistics, inventory, transportation, supplier, and production data | Historical sales data, market trends, promotions, and seasonality |

| Key Technologies | IoT sensors, AI, advanced analytics, cloud platforms | Statistical models, machine learning, forecasting software |

| Outcome | Improved supply chain responsiveness and risk mitigation | Accurate demand forecasts and inventory optimization |

| Users | Supply chain managers, logistics coordinators, operations teams | Demand planners, sales analysts, inventory managers |

| Typical Metrics | Order fulfillment rate, supply chain cycle time, delivery accuracy | Forecast accuracy, bias, inventory turnover |

Which is better?

Supply chain control towers offer comprehensive visibility and real-time monitoring across logistics operations, enabling proactive issue resolution and optimized resource allocation. Demand planning focuses specifically on forecasting customer demand to align inventory and production schedules, reducing stockouts and excess inventory. Choosing between them depends on whether the priority is holistic supply chain management (control tower) or precise demand forecasting (demand planning) for improved logistics efficiency.

Connection

A supply chain control tower provides real-time visibility and centralized monitoring of supply chain activities, enabling more accurate demand planning by detecting fluctuations and disruptions early. Demand planning leverages insights from the control tower to forecast customer demand effectively, aligning inventory and production schedules accordingly. This integration enhances responsiveness and reduces costs by synchronizing supply chain operations with market demand patterns.

Key Terms

**Demand Planning:**

Demand planning involves forecasting customer demand to ensure inventory levels match market needs, reducing stockouts and excess inventory. It leverages historical sales data, market trends, and statistical models to generate accurate demand forecasts. Explore how integrating advanced analytics can enhance your demand planning processes and improve supply chain efficiency.

Forecasting

Demand planning leverages historical sales data and market trends to generate accurate forecasts, helping businesses anticipate customer needs and optimize inventory levels. Supply chain control tower integrates real-time data from multiple sources, enabling dynamic forecasting adjustments and providing end-to-end visibility for proactive decision-making. Explore how combining advanced forecasting techniques in both domains can enhance supply chain efficiency and responsiveness.

Inventory Optimization

Demand planning leverages predictive analytics and historical sales data to forecast inventory requirements, minimizing stockouts and overstock situations. Supply chain control towers provide real-time visibility and end-to-end management, enabling dynamic adjustments to inventory levels based on current supply chain conditions. Explore how integrating demand planning with control tower capabilities enhances inventory optimization and operational efficiency.

Source and External Links

What is Demand Planning and Why is It Important? - TechTarget - Demand planning is the process of forecasting product or service demand to produce and deliver efficiently, involving statistical forecasting and alignment with supply chain management processes to optimize inventory and customer satisfaction.

What Is Demand Planning & How Is It Important to Supply Chain? - Michigan State University - Demand planning forecasts product demand to balance inventory levels, improve supply chain efficiency, and maximize profitability by considering factors like product lifecycle, statistical forecasting, and trade promotions.

What is Demand Planning? Importance & Our Process - Demand Planning Net - Demand planning is the art and science of forecasting customer demand to optimize supply chain operations and business planning, using quantitative modeling, machine learning forecasts, and customer intelligence to improve value chain collaboration.

dowidth.com

dowidth.com