Robotic Process Automation (RPA) in logistics streamlines repetitive tasks such as order processing and inventory management, significantly reducing manual errors and operational costs. Machine Learning optimization enhances logistics by analyzing vast datasets to predict demand, optimize routes, and improve supply chain efficiency through adaptive algorithms. Explore how integrating RPA and Machine Learning can transform logistics operations for maximum productivity and agility.

Why it is important

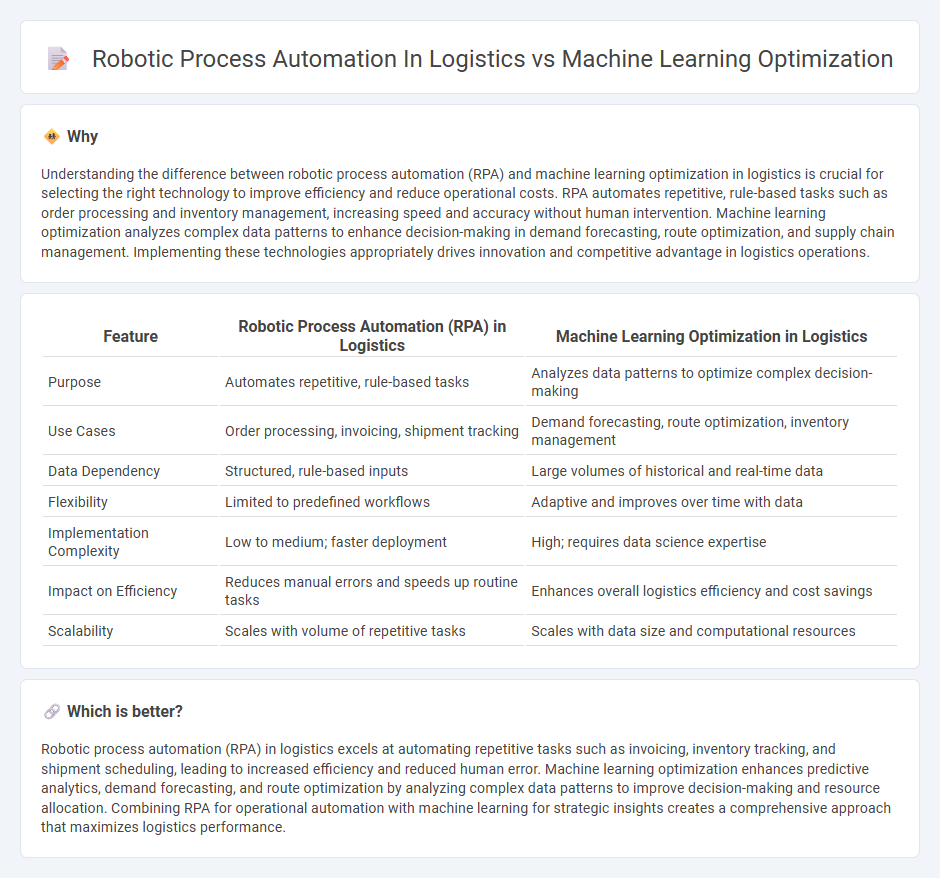

Understanding the difference between robotic process automation (RPA) and machine learning optimization in logistics is crucial for selecting the right technology to improve efficiency and reduce operational costs. RPA automates repetitive, rule-based tasks such as order processing and inventory management, increasing speed and accuracy without human intervention. Machine learning optimization analyzes complex data patterns to enhance decision-making in demand forecasting, route optimization, and supply chain management. Implementing these technologies appropriately drives innovation and competitive advantage in logistics operations.

Comparison Table

| Feature | Robotic Process Automation (RPA) in Logistics | Machine Learning Optimization in Logistics |

|---|---|---|

| Purpose | Automates repetitive, rule-based tasks | Analyzes data patterns to optimize complex decision-making |

| Use Cases | Order processing, invoicing, shipment tracking | Demand forecasting, route optimization, inventory management |

| Data Dependency | Structured, rule-based inputs | Large volumes of historical and real-time data |

| Flexibility | Limited to predefined workflows | Adaptive and improves over time with data |

| Implementation Complexity | Low to medium; faster deployment | High; requires data science expertise |

| Impact on Efficiency | Reduces manual errors and speeds up routine tasks | Enhances overall logistics efficiency and cost savings |

| Scalability | Scales with volume of repetitive tasks | Scales with data size and computational resources |

Which is better?

Robotic process automation (RPA) in logistics excels at automating repetitive tasks such as invoicing, inventory tracking, and shipment scheduling, leading to increased efficiency and reduced human error. Machine learning optimization enhances predictive analytics, demand forecasting, and route optimization by analyzing complex data patterns to improve decision-making and resource allocation. Combining RPA for operational automation with machine learning for strategic insights creates a comprehensive approach that maximizes logistics performance.

Connection

Robotic process automation (RPA) in logistics streamlines repetitive tasks such as inventory management and shipment tracking, enhancing operational efficiency. Machine learning optimization analyzes large datasets to predict demand patterns and optimize routing, which complements RPA by improving decision-making accuracy. Integrating RPA with machine learning enables logistics companies to automate complex workflows while continuously refining processes based on real-time data insights.

Key Terms

**Machine Learning Optimization in Logistics:**

Machine learning optimization in logistics enhances route planning, demand forecasting, and inventory management by utilizing predictive analytics and real-time data processing to reduce operational costs and improve delivery efficiency. Algorithms analyze vast datasets to optimize supply chain workflows, minimize delays, and adapt to changing market conditions. Explore how machine learning transforms logistics to unlock new levels of productivity and accuracy.

Predictive Analytics

Machine learning optimization leverages predictive analytics to forecast demand, enhance route planning, and reduce operational costs by analyzing large datasets in logistics. Robotic Process Automation (RPA) streamlines repetitive tasks such as inventory management and shipment tracking but lacks the advanced predictive capabilities of machine learning. Explore how integrating these technologies can revolutionize logistics efficiency and accuracy.

Route Optimization

Machine learning optimization leverages algorithms and historical data to predict and improve delivery routes, enhancing efficiency and reducing fuel consumption in logistics. Robotic process automation (RPA) automates repetitive tasks like order processing and shipment tracking but relies on predefined rules rather than adaptive learning models. Discover how integrating machine learning and RPA can transform route optimization for logistics companies.

Source and External Links

Machine Learning Optimization - Why is it so Important? - Machine learning optimization involves methods like random and grid searches as well as Bayesian and evolutionary optimization to iteratively improve model accuracy by fine-tuning hyperparameters and reducing error.

Introduction to Optimization for Machine Learning [Lecture] - Optimization in ML centers on minimizing loss functions such as cross-entropy or mean squared error using gradient descent methods to efficiently update model parameters and enhance performance.

Optimization Algorithms in Machine Learning - Optimization algorithms in ML adjust model parameters to minimize errors using techniques including gradient descent variants, Bayesian optimization, and constrained optimization methods, tailored for tasks like classification and regression.

dowidth.com

dowidth.com