Middle mile optimization enhances supply chain efficiency by improving transportation and distribution between suppliers and warehouses, reducing transit times and costs. Demand forecasting uses historical sales data and predictive analytics to anticipate customer needs and align inventory levels accordingly. Discover how integrating these strategies can transform your logistics operations and drive business growth.

Why it is important

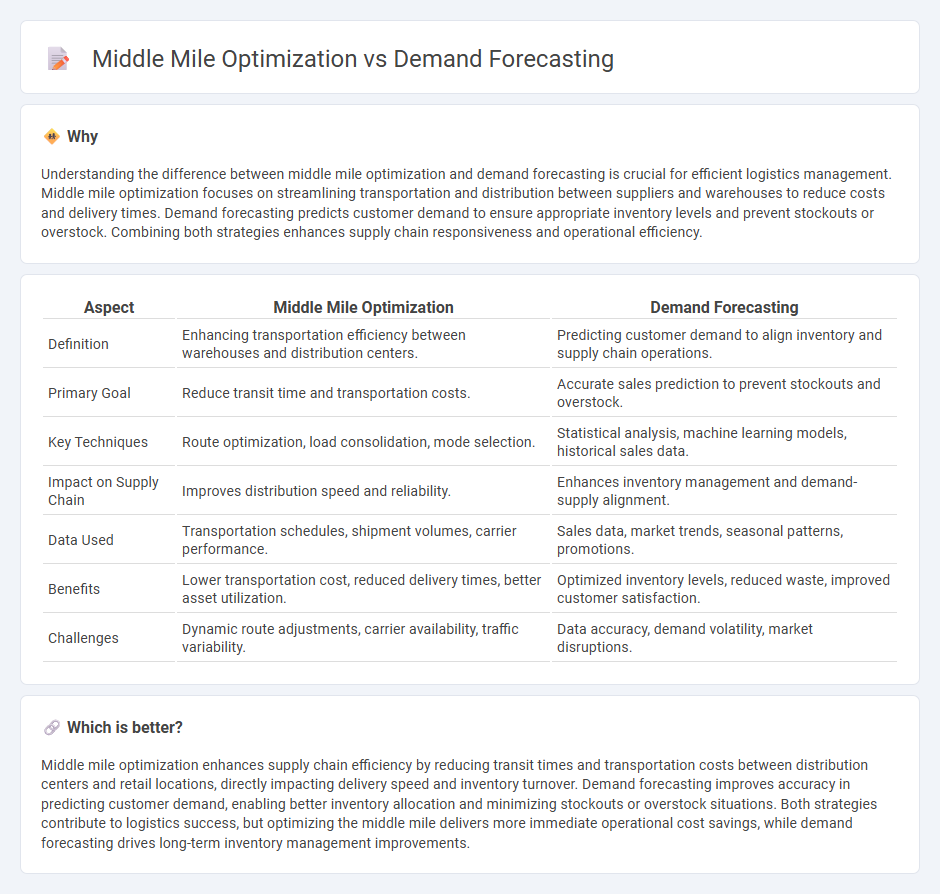

Understanding the difference between middle mile optimization and demand forecasting is crucial for efficient logistics management. Middle mile optimization focuses on streamlining transportation and distribution between suppliers and warehouses to reduce costs and delivery times. Demand forecasting predicts customer demand to ensure appropriate inventory levels and prevent stockouts or overstock. Combining both strategies enhances supply chain responsiveness and operational efficiency.

Comparison Table

| Aspect | Middle Mile Optimization | Demand Forecasting |

|---|---|---|

| Definition | Enhancing transportation efficiency between warehouses and distribution centers. | Predicting customer demand to align inventory and supply chain operations. |

| Primary Goal | Reduce transit time and transportation costs. | Accurate sales prediction to prevent stockouts and overstock. |

| Key Techniques | Route optimization, load consolidation, mode selection. | Statistical analysis, machine learning models, historical sales data. |

| Impact on Supply Chain | Improves distribution speed and reliability. | Enhances inventory management and demand-supply alignment. |

| Data Used | Transportation schedules, shipment volumes, carrier performance. | Sales data, market trends, seasonal patterns, promotions. |

| Benefits | Lower transportation cost, reduced delivery times, better asset utilization. | Optimized inventory levels, reduced waste, improved customer satisfaction. |

| Challenges | Dynamic route adjustments, carrier availability, traffic variability. | Data accuracy, demand volatility, market disruptions. |

Which is better?

Middle mile optimization enhances supply chain efficiency by reducing transit times and transportation costs between distribution centers and retail locations, directly impacting delivery speed and inventory turnover. Demand forecasting improves accuracy in predicting customer demand, enabling better inventory allocation and minimizing stockouts or overstock situations. Both strategies contribute to logistics success, but optimizing the middle mile delivers more immediate operational cost savings, while demand forecasting drives long-term inventory management improvements.

Connection

Middle mile optimization relies heavily on accurate demand forecasting to efficiently allocate transportation resources and reduce delivery times. By predicting customer demand patterns, companies can streamline inventory flow between warehouses and distribution centers, minimizing costs and improving service levels. Effective demand forecasting enhances route planning and load consolidation, making middle mile logistics more responsive and cost-effective.

Key Terms

**Demand Forecasting:**

Demand forecasting uses historical sales data, market trends, and predictive analytics to estimate future product demand, enabling businesses to optimize inventory levels and reduce stockouts. Accurate demand forecasting improves supply chain efficiency by aligning production schedules with anticipated customer needs. Explore how advanced demand forecasting techniques can transform your supply chain strategy.

Historical Data Analysis

Historical data analysis plays a critical role in demand forecasting by identifying patterns, trends, and seasonality to predict future customer demand accurately. In middle mile optimization, historical data helps analyze transit times, delivery routes, and capacity utilization to enhance shipping efficiency and reduce costs. Explore deeper insights on leveraging historical data for optimizing both demand forecasting and middle mile logistics.

Predictive Analytics

Demand forecasting leverages predictive analytics to analyze historical sales data and market trends, enabling businesses to anticipate future customer demand with high accuracy. Middle mile optimization uses predictive models to enhance transportation routes and warehouse management, reducing costs and improving delivery efficiency between suppliers and distribution centers. Explore more about how predictive analytics transforms supply chain efficiency in these critical areas.

Source and External Links

Types of Demand Forecast - GeeksforGeeks - Demand forecasting uses past data and predictive analysis to estimate future customer demand, helping businesses optimize inventory, production, pricing, and operational decisions by projecting total sales and revenue for upcoming periods.

Demand Forecasting Guide: Definition, Types, Methods, Examples - Demand forecasting estimates future product demand to guide production and inventory, using methods like trend projection, market research, and sales force composite to produce accurate sales forecasts.

Demand forecasting - Wikipedia - Demand forecasting, also called demand planning and sales forecasting, predicts the quantity of goods or services needed at a future time, using qualitative methods (expert opinion) or quantitative methods (data analytics) to optimize supply chain management and resource allocation.

dowidth.com

dowidth.com