Reverse logistics solutions streamline the return, recycling, and disposal of products, reducing waste and enhancing sustainability in supply chains. Inventory management focuses on tracking, storing, and replenishing stock to meet customer demand efficiently while minimizing holding costs. Explore how integrating reverse logistics with inventory management can optimize operational efficiency and improve profitability.

Why it is important

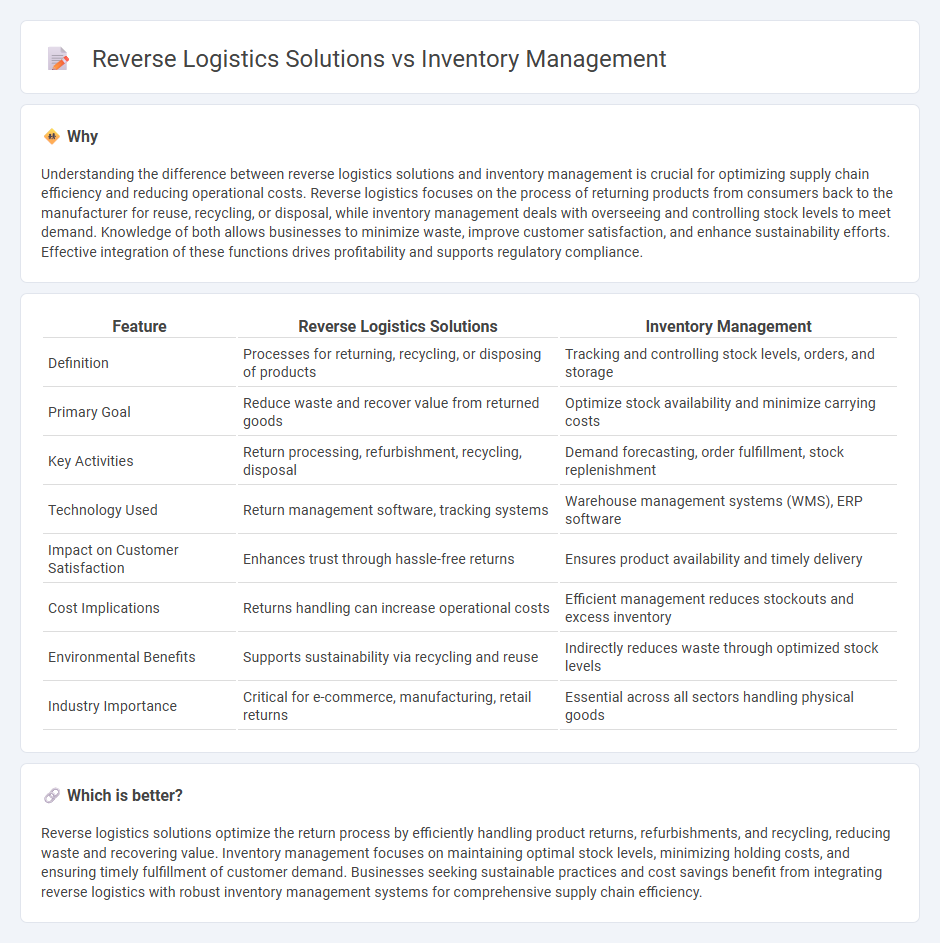

Understanding the difference between reverse logistics solutions and inventory management is crucial for optimizing supply chain efficiency and reducing operational costs. Reverse logistics focuses on the process of returning products from consumers back to the manufacturer for reuse, recycling, or disposal, while inventory management deals with overseeing and controlling stock levels to meet demand. Knowledge of both allows businesses to minimize waste, improve customer satisfaction, and enhance sustainability efforts. Effective integration of these functions drives profitability and supports regulatory compliance.

Comparison Table

| Feature | Reverse Logistics Solutions | Inventory Management |

|---|---|---|

| Definition | Processes for returning, recycling, or disposing of products | Tracking and controlling stock levels, orders, and storage |

| Primary Goal | Reduce waste and recover value from returned goods | Optimize stock availability and minimize carrying costs |

| Key Activities | Return processing, refurbishment, recycling, disposal | Demand forecasting, order fulfillment, stock replenishment |

| Technology Used | Return management software, tracking systems | Warehouse management systems (WMS), ERP software |

| Impact on Customer Satisfaction | Enhances trust through hassle-free returns | Ensures product availability and timely delivery |

| Cost Implications | Returns handling can increase operational costs | Efficient management reduces stockouts and excess inventory |

| Environmental Benefits | Supports sustainability via recycling and reuse | Indirectly reduces waste through optimized stock levels |

| Industry Importance | Critical for e-commerce, manufacturing, retail returns | Essential across all sectors handling physical goods |

Which is better?

Reverse logistics solutions optimize the return process by efficiently handling product returns, refurbishments, and recycling, reducing waste and recovering value. Inventory management focuses on maintaining optimal stock levels, minimizing holding costs, and ensuring timely fulfillment of customer demand. Businesses seeking sustainable practices and cost savings benefit from integrating reverse logistics with robust inventory management systems for comprehensive supply chain efficiency.

Connection

Reverse logistics solutions enhance inventory management by streamlining the process of returning, refurbishing, and restocking products, reducing waste and improving stock accuracy. Efficient reverse logistics systems provide valuable data on product returns and defects, enabling better forecasting and replenishment strategies. Integrating reverse logistics with inventory management minimizes holding costs and maximizes resource utilization across supply chains.

Key Terms

**Inventory Management:**

Inventory management optimizes stock levels by tracking product quantities, demand forecasts, and reorder points to minimize holding costs and prevent stockouts. It employs technologies like barcode scanning, RFID, and inventory management software to enhance accuracy and real-time visibility across supply chains. Discover more about how advanced inventory management solutions drive operational efficiency and profitability.

Stock Keeping Unit (SKU)

Effective inventory management optimizes Stock Keeping Unit (SKU) tracking to ensure accurate demand forecasting and reduce stockouts or overstock situations. Reverse logistics solutions prioritize the seamless handling of returned SKUs, focusing on refurbishment, recycling, or resale to minimize losses and enhance sustainability. Explore our comprehensive insights to maximize SKU efficiency and streamline your supply chain operations.

Reorder Point

Inventory management optimizes stock levels using the Reorder Point (ROP) to trigger timely replenishment, preventing stockouts and excess inventory. Reverse logistics solutions integrate ROP by managing returns and refurbishments efficiently, ensuring returned items are processed and restocked promptly to maintain supply chain continuity. Explore how advanced reorder point strategies can streamline both inventory management and reverse logistics for improved operational efficiency.

Source and External Links

What Is Inventory Management? Benefits, Types, & Techniques - Inventory management is the process of tracking and controlling the flow of goods from procurement and receiving to storage, sales, and replenishment, involving demand planning, order placement, delivery verification, and continuous optimization through audits and reporting.

Inventory Management: How it Works and Tools (2025) - Shopify - Effective inventory management employs techniques like economic order quantity, demand planning, inventory counts, and technologies such as barcodes and RFID to balance stock levels, avoid overstocking or stockouts, and improve cash flow.

Inventory Management Guide + Methods & Examples - Extensiv - Inventory management systems range from manual spreadsheets to automated solutions and ERP software, supporting processes like sourcing, storing, selling, and multichannel tracking to optimize inventory accuracy and availability.

dowidth.com

dowidth.com