Cold chain management ensures temperature-sensitive products maintain efficacy through controlled environments during transportation and storage, critical for pharmaceuticals and perishable goods. Warehousing focuses on the organized storage, inventory management, and distribution of goods, optimizing space utilization and operational efficiency. Explore the unique challenges and solutions in cold chain management versus warehousing to enhance your logistics strategy.

Why it is important

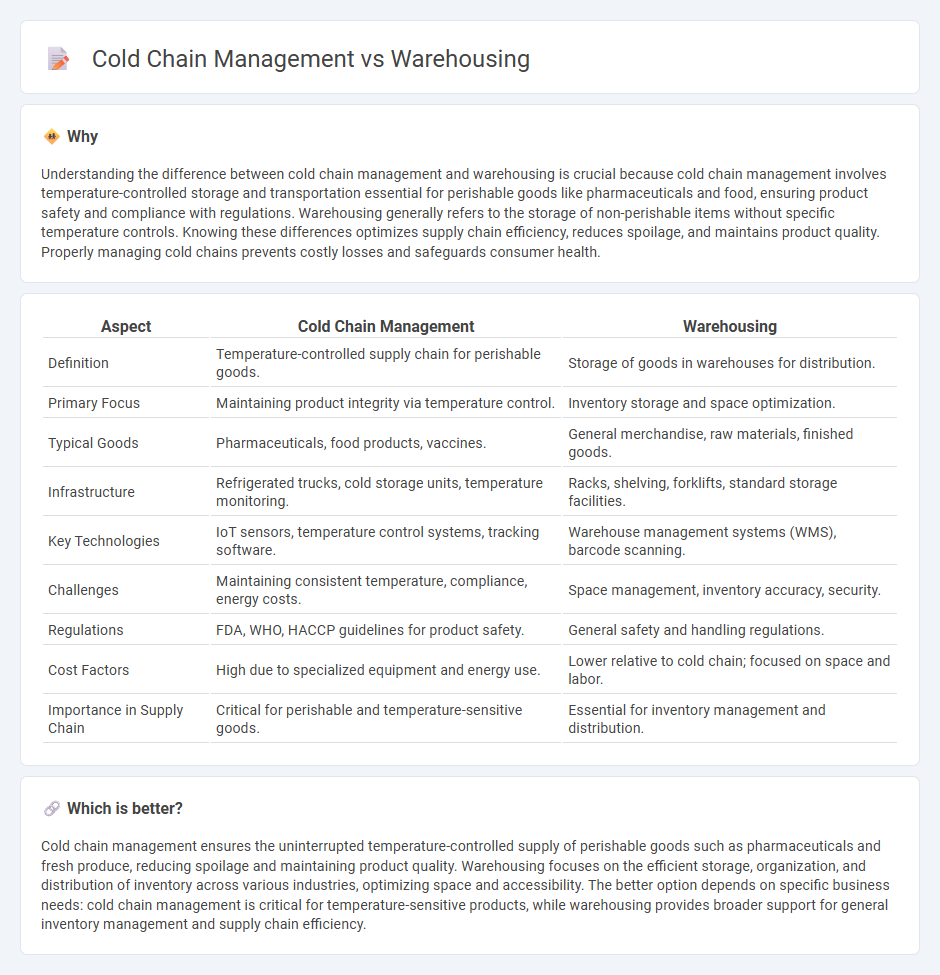

Understanding the difference between cold chain management and warehousing is crucial because cold chain management involves temperature-controlled storage and transportation essential for perishable goods like pharmaceuticals and food, ensuring product safety and compliance with regulations. Warehousing generally refers to the storage of non-perishable items without specific temperature controls. Knowing these differences optimizes supply chain efficiency, reduces spoilage, and maintains product quality. Properly managing cold chains prevents costly losses and safeguards consumer health.

Comparison Table

| Aspect | Cold Chain Management | Warehousing |

|---|---|---|

| Definition | Temperature-controlled supply chain for perishable goods. | Storage of goods in warehouses for distribution. |

| Primary Focus | Maintaining product integrity via temperature control. | Inventory storage and space optimization. |

| Typical Goods | Pharmaceuticals, food products, vaccines. | General merchandise, raw materials, finished goods. |

| Infrastructure | Refrigerated trucks, cold storage units, temperature monitoring. | Racks, shelving, forklifts, standard storage facilities. |

| Key Technologies | IoT sensors, temperature control systems, tracking software. | Warehouse management systems (WMS), barcode scanning. |

| Challenges | Maintaining consistent temperature, compliance, energy costs. | Space management, inventory accuracy, security. |

| Regulations | FDA, WHO, HACCP guidelines for product safety. | General safety and handling regulations. |

| Cost Factors | High due to specialized equipment and energy use. | Lower relative to cold chain; focused on space and labor. |

| Importance in Supply Chain | Critical for perishable and temperature-sensitive goods. | Essential for inventory management and distribution. |

Which is better?

Cold chain management ensures the uninterrupted temperature-controlled supply of perishable goods such as pharmaceuticals and fresh produce, reducing spoilage and maintaining product quality. Warehousing focuses on the efficient storage, organization, and distribution of inventory across various industries, optimizing space and accessibility. The better option depends on specific business needs: cold chain management is critical for temperature-sensitive products, while warehousing provides broader support for general inventory management and supply chain efficiency.

Connection

Cold chain management ensures temperature-controlled storage and transportation of perishable goods, which directly impacts warehousing operations by requiring specialized refrigeration infrastructure and monitoring systems. Warehousing in cold chain logistics demands precise environmental controls to maintain product integrity and compliance with safety standards. Integration of cold chain management with warehousing optimizes inventory turnover, reduces spoilage, and enhances overall supply chain efficiency.

Key Terms

**Warehousing:**

Warehousing involves the systematic storage of goods in optimized facilities designed to maintain product integrity, streamline inventory management, and support efficient order fulfillment. Modern warehousing integrates advanced technologies like automated retrieval systems and real-time inventory tracking to enhance operational efficiency and reduce handling errors. Explore detailed insights on warehousing strategies and innovations to boost supply chain performance.

Inventory Management

Warehousing primarily focuses on the storage and organization of inventory under standardized conditions to maintain product integrity, while cold chain management involves specialized temperature-controlled environments essential for preserving perishable goods like pharmaceuticals and food items. Inventory management in warehousing emphasizes efficient space utilization and stock rotation, whereas cold chain management requires stringent monitoring of temperature, humidity, and time-sensitive handling to prevent spoilage. Discover more about optimizing inventory strategies within warehousing and cold chain management systems.

Order Fulfillment

Warehousing centers on the storage, organization, and timely retrieval of goods, emphasizing efficient inventory management and space optimization to facilitate rapid order fulfillment. Cold chain management integrates temperature-controlled storage and transportation to preserve perishable items, ensuring product quality and safety from storage to customer delivery. Explore deeper insights on how each approach shapes order fulfillment efficiency and customer satisfaction.

Source and External Links

What Is Warehousing? Definition, Types, and Key Features - Warehousing involves storing goods until they are ready for transport and includes planning space, managing inventory, climate control, and product retrieval, playing a crucial role in supply chain management with various warehouse types like private, public, and bonded warehouses.

What is Warehousing? Definition, Advantages, and Functions ... - Warehousing is the organized storage and management of goods until distribution or sale, expanding beyond storage to include inventory management, order fulfillment, and value-added services such as product customization and returns processing.

What is warehousing? A guide to logistics - Adobe Experience Cloud - Warehousing is the process of storing physical inventory for sale or distribution to speed deliveries and reduce costs, especially important for ecommerce businesses placing products in strategic locations for same-day delivery capability.

dowidth.com

dowidth.com