Cold chain traceability ensures the integrity of temperature-sensitive goods by monitoring environmental conditions throughout the supply chain, minimizing spoilage and regulatory risks. Fleet management optimizes vehicle routes, maintenance, and driver performance to improve delivery efficiency and reduce operational costs. Discover how integrating cold chain traceability with advanced fleet management can revolutionize your logistics operations.

Why it is important

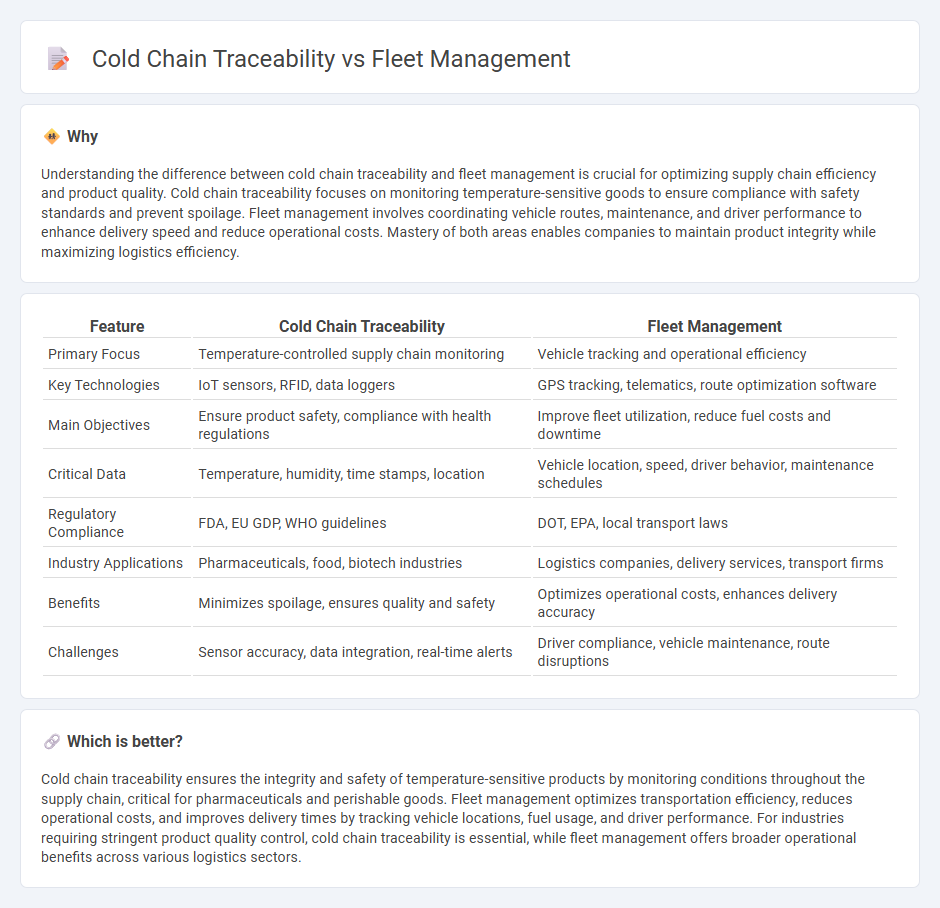

Understanding the difference between cold chain traceability and fleet management is crucial for optimizing supply chain efficiency and product quality. Cold chain traceability focuses on monitoring temperature-sensitive goods to ensure compliance with safety standards and prevent spoilage. Fleet management involves coordinating vehicle routes, maintenance, and driver performance to enhance delivery speed and reduce operational costs. Mastery of both areas enables companies to maintain product integrity while maximizing logistics efficiency.

Comparison Table

| Feature | Cold Chain Traceability | Fleet Management |

|---|---|---|

| Primary Focus | Temperature-controlled supply chain monitoring | Vehicle tracking and operational efficiency |

| Key Technologies | IoT sensors, RFID, data loggers | GPS tracking, telematics, route optimization software |

| Main Objectives | Ensure product safety, compliance with health regulations | Improve fleet utilization, reduce fuel costs and downtime |

| Critical Data | Temperature, humidity, time stamps, location | Vehicle location, speed, driver behavior, maintenance schedules |

| Regulatory Compliance | FDA, EU GDP, WHO guidelines | DOT, EPA, local transport laws |

| Industry Applications | Pharmaceuticals, food, biotech industries | Logistics companies, delivery services, transport firms |

| Benefits | Minimizes spoilage, ensures quality and safety | Optimizes operational costs, enhances delivery accuracy |

| Challenges | Sensor accuracy, data integration, real-time alerts | Driver compliance, vehicle maintenance, route disruptions |

Which is better?

Cold chain traceability ensures the integrity and safety of temperature-sensitive products by monitoring conditions throughout the supply chain, critical for pharmaceuticals and perishable goods. Fleet management optimizes transportation efficiency, reduces operational costs, and improves delivery times by tracking vehicle locations, fuel usage, and driver performance. For industries requiring stringent product quality control, cold chain traceability is essential, while fleet management offers broader operational benefits across various logistics sectors.

Connection

Cold chain traceability relies heavily on fleet management technologies to monitor temperature-sensitive shipments in real time, ensuring compliance with regulatory standards and preventing spoilage. GPS tracking and IoT sensors integrated into fleet management systems provide continuous visibility into the location and environmental conditions of refrigerated vehicles. This seamless connection reduces delivery delays, enhances inventory accuracy, and optimizes route planning for perishable goods logistics.

Key Terms

Fleet management:

Fleet management optimizes vehicle utilization, route planning, and maintenance schedules to reduce operational costs and improve delivery efficiency. Advanced telematics and GPS tracking enable real-time monitoring of fleet performance and driver behavior, enhancing safety and compliance. Explore more about how innovative fleet management solutions transform logistics and drive business growth.

Telematics

Telematics integrates GPS tracking, vehicle diagnostics, and real-time communication to enhance fleet management efficiency, ensuring optimized routing, reduced fuel consumption, and proactive maintenance. In cold chain traceability, telematics ensures temperature-sensitive goods are monitored continuously, providing alerts for any deviations to maintain product integrity from source to destination. Explore how advanced telematics solutions can transform both fleet management and cold chain traceability for your business.

Route optimization

Fleet management integrates GPS tracking, real-time traffic data, and telematics to enhance route optimization, reducing fuel consumption and delivery times. Cold chain traceability leverages IoT sensors and temperature monitoring to ensure perishable goods maintain optimal conditions throughout transit, while optimizing delivery routes to prevent spoilage. Explore advanced route optimization techniques to improve efficiency and reliability in both fleet management and cold chain logistics.

Source and External Links

What Is Fleet Management? (A Fleet Managers Guide) - Geotab - Fleet management is the process of overseeing and optimizing a fleet of vehicles, involving vehicle acquisition, maintenance, driver behavior management, cost reduction, safety, and compliance, aiming for continual improvement and efficiency including emerging goals like lowering emissions with electric vehicles.

What is Fleet Management? - IBM - Fleet management includes maintaining and optimizing a fleet's operational efficiency through vehicle procurement, maintenance, driver safety and recruitment, fuel management, compliance with regulations, and data analytics often supported by fleet management software to improve performance and reduce costs.

Fleet management - Wikipedia - Fleet management covers the oversight of commercial vehicles, private work vehicles, and specialized equipment, incorporating vehicle leasing, maintenance, compliance, telematics, driver and fuel management, risk reduction, and enhancing efficiency and productivity, implemented either in-house or via outsourced providers.

dowidth.com

dowidth.com