Yard management focuses on controlling and optimizing the movement and storage of trailers and vehicles within a facility's yard, enhancing space utilization and reducing wait times. Dock management concentrates on scheduling and coordinating loading and unloading activities at docks to improve turnaround times and operational efficiency. Discover how integrating both systems can streamline your supply chain operations.

Why it is important

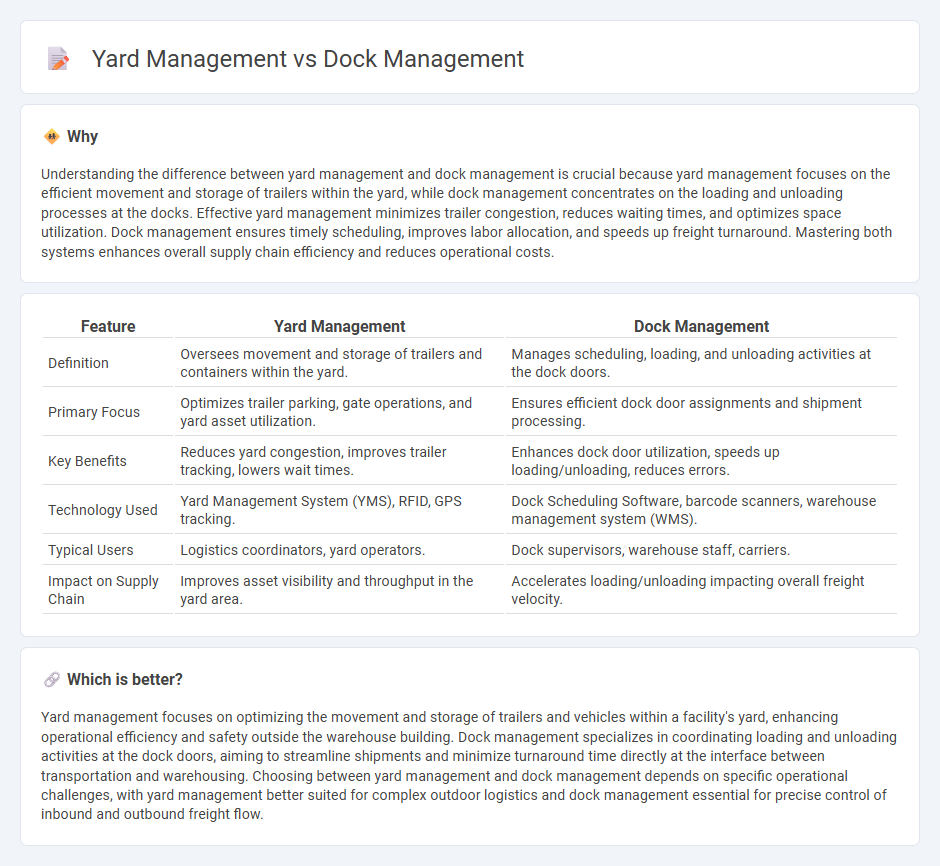

Understanding the difference between yard management and dock management is crucial because yard management focuses on the efficient movement and storage of trailers within the yard, while dock management concentrates on the loading and unloading processes at the docks. Effective yard management minimizes trailer congestion, reduces waiting times, and optimizes space utilization. Dock management ensures timely scheduling, improves labor allocation, and speeds up freight turnaround. Mastering both systems enhances overall supply chain efficiency and reduces operational costs.

Comparison Table

| Feature | Yard Management | Dock Management |

|---|---|---|

| Definition | Oversees movement and storage of trailers and containers within the yard. | Manages scheduling, loading, and unloading activities at the dock doors. |

| Primary Focus | Optimizes trailer parking, gate operations, and yard asset utilization. | Ensures efficient dock door assignments and shipment processing. |

| Key Benefits | Reduces yard congestion, improves trailer tracking, lowers wait times. | Enhances dock door utilization, speeds up loading/unloading, reduces errors. |

| Technology Used | Yard Management System (YMS), RFID, GPS tracking. | Dock Scheduling Software, barcode scanners, warehouse management system (WMS). |

| Typical Users | Logistics coordinators, yard operators. | Dock supervisors, warehouse staff, carriers. |

| Impact on Supply Chain | Improves asset visibility and throughput in the yard area. | Accelerates loading/unloading impacting overall freight velocity. |

Which is better?

Yard management focuses on optimizing the movement and storage of trailers and vehicles within a facility's yard, enhancing operational efficiency and safety outside the warehouse building. Dock management specializes in coordinating loading and unloading activities at the dock doors, aiming to streamline shipments and minimize turnaround time directly at the interface between transportation and warehousing. Choosing between yard management and dock management depends on specific operational challenges, with yard management better suited for complex outdoor logistics and dock management essential for precise control of inbound and outbound freight flow.

Connection

Yard management optimizes the movement and storage of trailers and inventory within the yard, directly impacting the efficiency of dock management by ensuring timely trailer scheduling and gate operations. Proper coordination between yard and dock management minimizes loading and unloading delays, enhances asset utilization, and improves overall supply chain throughput. Advanced yard management systems integrate with dock scheduling software to streamline workflows, reduce detention times, and increase operational visibility.

Key Terms

Dock Management:

Dock management involves coordinating inbound and outbound shipments to optimize loading and unloading processes, reducing wait times and improving supply chain efficiency. It includes scheduling dock doors, managing labor resources, and ensuring compliance with safety regulations to streamline operations within warehouse or distribution center premises. Discover how mastering dock management can enhance your logistics performance and warehouse productivity.

Dock Scheduling

Dock scheduling optimizes the allocation of time slots for inbound and outbound shipments, minimizing wait times and ensuring smooth loading and unloading processes at the dock. While dock management focuses on overseeing dock activities and equipment, yard management regulates the movement and storage of trailers and containers within the yard area. Explore more about how integrated dock and yard management solutions enhance overall supply chain efficiency.

Loading/Unloading Operations

Dock management optimizes loading and unloading operations by coordinating dock schedules, labor, and equipment usage to minimize turnaround time and maximize throughput efficiency. Yard management focuses on the movement and placement of trailers and containers within the yard, ensuring smooth transitions between docks and storage areas while preventing congestion. Explore how integrating dock and yard management systems can streamline overall supply chain operations.

Source and External Links

What is Dock Management? | Basics & Importance - Loadsmart Blog - Dock management involves coordinating deliveries, workers, and equipment at loading docks, including scheduling dock appointments, assigning dock doors by shipment type, coordinating staff and equipment, and preparing for arrivals to avoid congestion and delays.

Warehouse Dock Management: What It Is and Tips To Improve It - Warehouse dock management coordinates all loading/unloading activities with scheduling, staffing, equipment maintenance, and safety protocols to reduce bottlenecks, improve turnaround times, and enhance efficiency and safety.

How Dock Management Systems Benefit More than Just Warehouse Operations - Modern dock management systems improve resource utilization, provide real-time visibility, reduce carrier wait times, and optimize overall warehouse and supply chain operations by coordinating dock activities effectively.

dowidth.com

dowidth.com