Milk run logistics optimizes transportation by consolidating multiple deliveries into a single route, reducing costs and improving efficiency for supply chain operations. Distribution centers act as centralized hubs where goods are stored, sorted, and dispatched to various destinations, enabling streamlined inventory management and faster order fulfillment. Explore the key differences and benefits of milk run versus distribution center strategies to enhance your logistics performance.

Why it is important

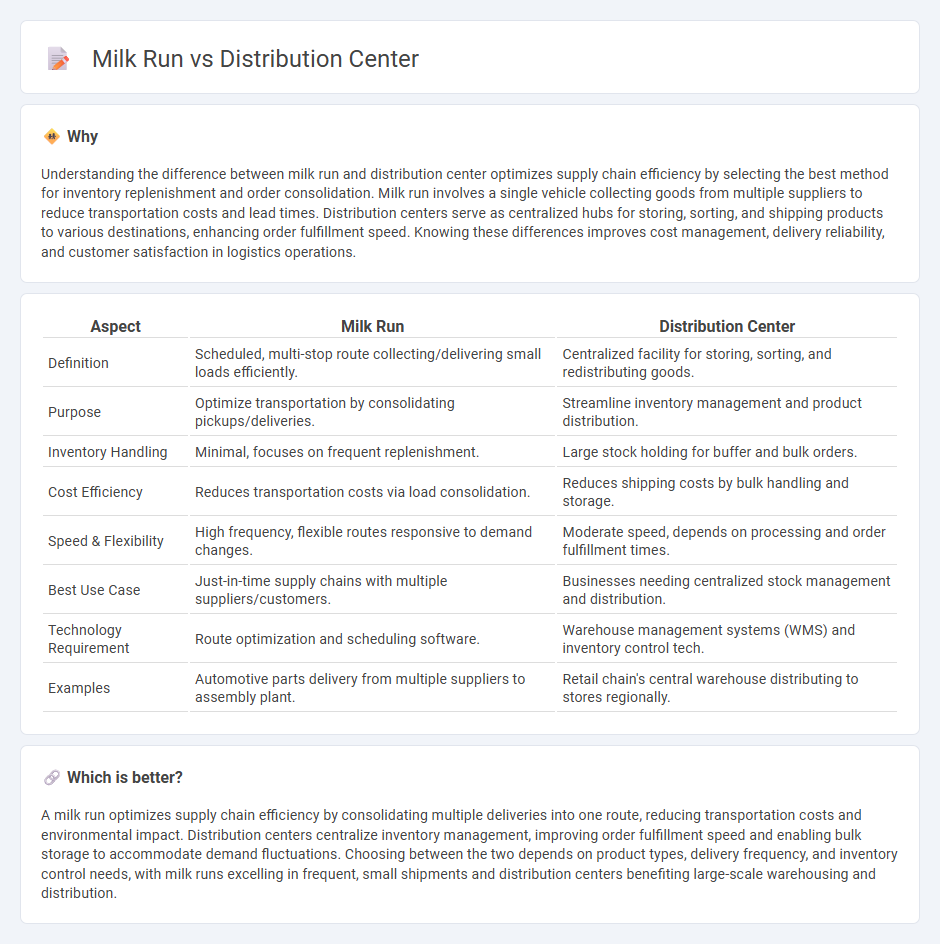

Understanding the difference between milk run and distribution center optimizes supply chain efficiency by selecting the best method for inventory replenishment and order consolidation. Milk run involves a single vehicle collecting goods from multiple suppliers to reduce transportation costs and lead times. Distribution centers serve as centralized hubs for storing, sorting, and shipping products to various destinations, enhancing order fulfillment speed. Knowing these differences improves cost management, delivery reliability, and customer satisfaction in logistics operations.

Comparison Table

| Aspect | Milk Run | Distribution Center |

|---|---|---|

| Definition | Scheduled, multi-stop route collecting/delivering small loads efficiently. | Centralized facility for storing, sorting, and redistributing goods. |

| Purpose | Optimize transportation by consolidating pickups/deliveries. | Streamline inventory management and product distribution. |

| Inventory Handling | Minimal, focuses on frequent replenishment. | Large stock holding for buffer and bulk orders. |

| Cost Efficiency | Reduces transportation costs via load consolidation. | Reduces shipping costs by bulk handling and storage. |

| Speed & Flexibility | High frequency, flexible routes responsive to demand changes. | Moderate speed, depends on processing and order fulfillment times. |

| Best Use Case | Just-in-time supply chains with multiple suppliers/customers. | Businesses needing centralized stock management and distribution. |

| Technology Requirement | Route optimization and scheduling software. | Warehouse management systems (WMS) and inventory control tech. |

| Examples | Automotive parts delivery from multiple suppliers to assembly plant. | Retail chain's central warehouse distributing to stores regionally. |

Which is better?

A milk run optimizes supply chain efficiency by consolidating multiple deliveries into one route, reducing transportation costs and environmental impact. Distribution centers centralize inventory management, improving order fulfillment speed and enabling bulk storage to accommodate demand fluctuations. Choosing between the two depends on product types, delivery frequency, and inventory control needs, with milk runs excelling in frequent, small shipments and distribution centers benefiting large-scale warehousing and distribution.

Connection

Milk run logistics optimize supply chain efficiency by coordinating regular, scheduled pickups from multiple suppliers to a central distribution center. The distribution center acts as a pivotal hub for consolidating goods, streamlining inventory management, and facilitating timely delivery to downstream destinations. This integration reduces transportation costs, minimizes waste, and enhances overall distribution network responsiveness.

Key Terms

Centralized Storage

Centralized storage in distribution centers streamlines inventory management by consolidating goods in a single location, enhancing order accuracy and reducing storage costs. In contrast, the milk run system optimizes transportation by scheduling multiple pickups and deliveries, minimizing travel time and fuel consumption through coordinated routing. Explore how these strategies improve supply chain efficiency and reduce operational expenses.

Route Optimization

Distribution centers centralize inventory storage and facilitate bulk shipments, streamlining supply chain operations through consolidated delivery routes. Milk run logistics employ optimized route planning to collect or deliver smaller quantities from multiple suppliers or customers in a single trip, minimizing transportation costs and improving efficiency. Explore how advanced route optimization strategies enhance both distribution center operations and milk run systems for superior supply chain performance.

Inventory Consolidation

Inventory consolidation in distribution centers involves centralizing stock to streamline storage and reduce handling costs, enhancing order accuracy and fulfillment speed. Milk run logistics optimize inventory consolidation by coordinating multiple supplier pickups into a single delivery route, reducing transportation costs and improving supply chain efficiency. Explore how integrating distribution centers with milk run strategies can revolutionize your inventory management.

Source and External Links

What Is a Distribution Center and How Do They Work? - A distribution center is a facility that receives goods, stores them for a short time, manages inventory, and ships products to resellers or end users, ensuring timely delivery through organized storage and shipping processes.

Distribution Centers Explained - Distribution centers combine warehouse and fulfillment functions by storing large inventories close to customers to facilitate fast, cost-effective picking, packing, and shipping of orders.

Logistics Distribution Center (DC): What is it and its ... - A distribution center is a logistics facility designed to receive, store, and ship goods, acting as an intermediary in the supply chain before goods reach wholesalers, retailers, or other warehouses.

dowidth.com

dowidth.com