Cross docking streamlines supply chain operations by transferring goods directly from inbound to outbound transportation with minimal storage time, enhancing efficiency and reducing inventory costs. Consolidation centers aggregate smaller shipments into larger loads, optimizing transportation costs and improving delivery reliability. Explore the key differences and benefits of cross docking versus consolidation centers to optimize your logistics strategy.

Why it is important

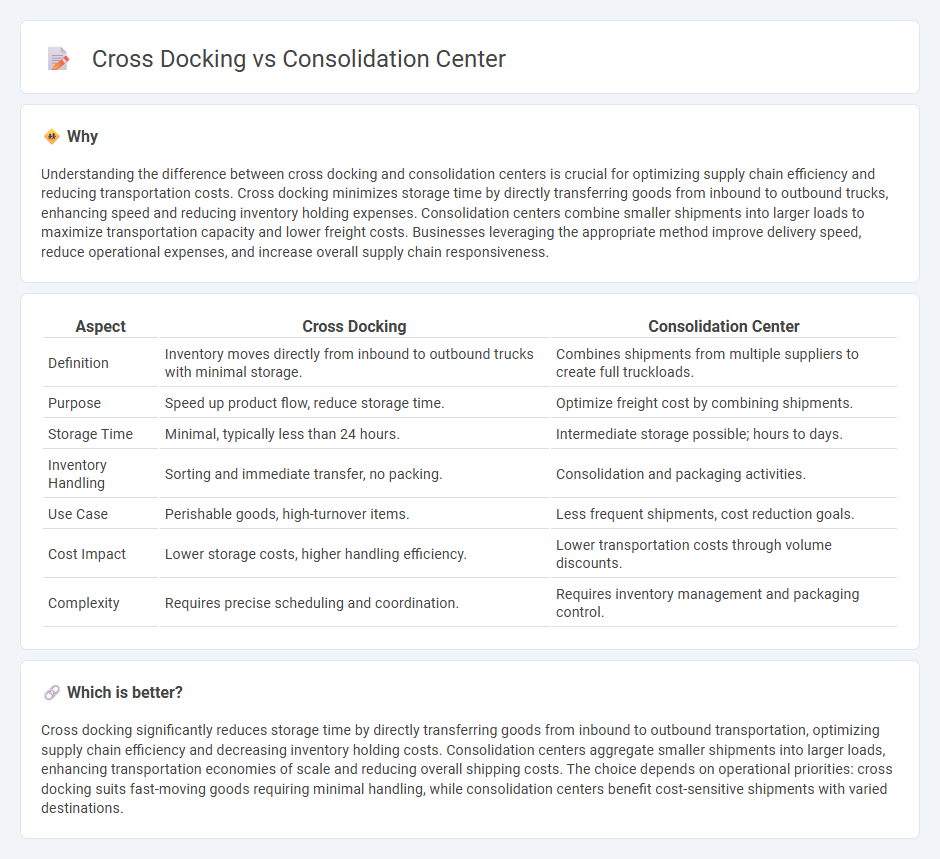

Understanding the difference between cross docking and consolidation centers is crucial for optimizing supply chain efficiency and reducing transportation costs. Cross docking minimizes storage time by directly transferring goods from inbound to outbound trucks, enhancing speed and reducing inventory holding expenses. Consolidation centers combine smaller shipments into larger loads to maximize transportation capacity and lower freight costs. Businesses leveraging the appropriate method improve delivery speed, reduce operational expenses, and increase overall supply chain responsiveness.

Comparison Table

| Aspect | Cross Docking | Consolidation Center |

|---|---|---|

| Definition | Inventory moves directly from inbound to outbound trucks with minimal storage. | Combines shipments from multiple suppliers to create full truckloads. |

| Purpose | Speed up product flow, reduce storage time. | Optimize freight cost by combining shipments. |

| Storage Time | Minimal, typically less than 24 hours. | Intermediate storage possible; hours to days. |

| Inventory Handling | Sorting and immediate transfer, no packing. | Consolidation and packaging activities. |

| Use Case | Perishable goods, high-turnover items. | Less frequent shipments, cost reduction goals. |

| Cost Impact | Lower storage costs, higher handling efficiency. | Lower transportation costs through volume discounts. |

| Complexity | Requires precise scheduling and coordination. | Requires inventory management and packaging control. |

Which is better?

Cross docking significantly reduces storage time by directly transferring goods from inbound to outbound transportation, optimizing supply chain efficiency and decreasing inventory holding costs. Consolidation centers aggregate smaller shipments into larger loads, enhancing transportation economies of scale and reducing overall shipping costs. The choice depends on operational priorities: cross docking suits fast-moving goods requiring minimal handling, while consolidation centers benefit cost-sensitive shipments with varied destinations.

Connection

Cross docking and consolidation centers both streamline supply chain efficiency by minimizing storage time and optimizing shipment loads. Cross docking involves direct transfer of goods from inbound to outbound transportation, reducing handling costs, while consolidation centers aggregate smaller shipments to achieve full truckload capacity, lowering transportation expenses. Their interconnected roles enhance logistics by accelerating delivery times and reducing operational costs across distribution networks.

Key Terms

**Consolidation Center:**

A consolidation center is a logistics facility where shipments from multiple suppliers are combined into a single, larger shipment to optimize transportation efficiency and reduce costs. This method improves inventory management and minimizes delivery frequency by merging smaller deliveries into one consolidated load. Explore more about how consolidation centers streamline supply chains and enhance operational performance.

Inbound Aggregation

Inbound aggregation in a consolidation center involves collecting shipments from multiple suppliers to create full truckloads, optimizing transportation efficiency and reducing costs. In contrast, cross docking focuses on the rapid transfer of goods from inbound to outbound transportation with minimal storage, aiming to expedite order fulfillment and reduce inventory holding. Explore detailed operational benefits and use cases to understand which method best suits your supply chain needs.

Storage Buffer

A consolidation center centralizes shipments from multiple suppliers, using a storage buffer to accumulate goods before dispatching them in full truckloads, which optimizes transportation efficiency but requires inventory holding space. Cross docking minimizes storage buffer use by directly transferring inbound goods to outbound shipments, reducing inventory holding time and storage costs while speeding up the supply chain. Explore the differences in storage buffer roles and logistics strategies to optimize your distribution network.

Source and External Links

Consolidation Center Definition and Meaning - A consolidation center is a logistics facility where multiple small shipments from different suppliers are gathered, combined into larger loads, and shipped together to reduce costs and improve efficiency.

How Walmart's Consolidation Centre Improves the Supply Chain - Walmart's consolidation centers enhance supply chain efficiency by combining smaller shipments into larger ones, utilizing automated technology to streamline product movement to stores.

Consolidation Centres - Consolidation centers are facilities where multiple shipments are combined into a single shipment to save on shipping costs and improve shipping efficiency.

dowidth.com

dowidth.com