Cold chain management ensures temperature-sensitive products maintain quality through controlled environments during storage and transportation, crucial for pharmaceuticals and perishable foods. Inventory management focuses on optimizing stock levels, tracking items efficiently, and minimizing holding costs to meet demand without overstocking. Explore the differences between these two logistics strategies for better supply chain efficiency.

Why it is important

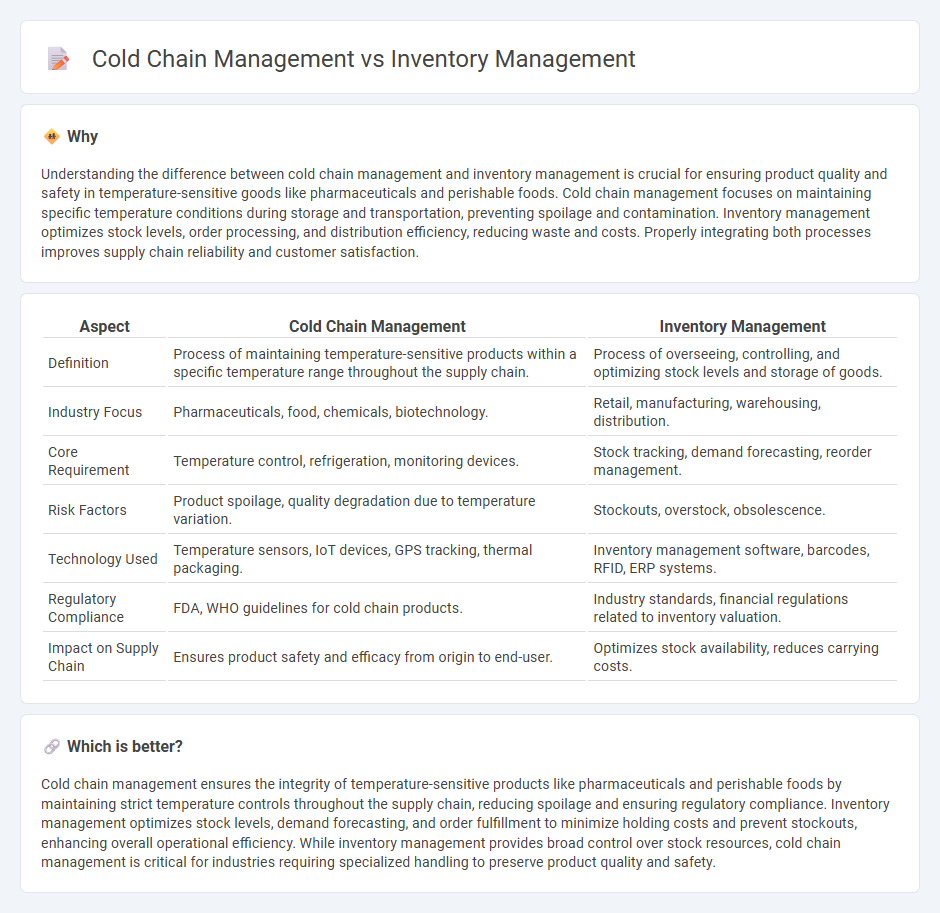

Understanding the difference between cold chain management and inventory management is crucial for ensuring product quality and safety in temperature-sensitive goods like pharmaceuticals and perishable foods. Cold chain management focuses on maintaining specific temperature conditions during storage and transportation, preventing spoilage and contamination. Inventory management optimizes stock levels, order processing, and distribution efficiency, reducing waste and costs. Properly integrating both processes improves supply chain reliability and customer satisfaction.

Comparison Table

| Aspect | Cold Chain Management | Inventory Management |

|---|---|---|

| Definition | Process of maintaining temperature-sensitive products within a specific temperature range throughout the supply chain. | Process of overseeing, controlling, and optimizing stock levels and storage of goods. |

| Industry Focus | Pharmaceuticals, food, chemicals, biotechnology. | Retail, manufacturing, warehousing, distribution. |

| Core Requirement | Temperature control, refrigeration, monitoring devices. | Stock tracking, demand forecasting, reorder management. |

| Risk Factors | Product spoilage, quality degradation due to temperature variation. | Stockouts, overstock, obsolescence. |

| Technology Used | Temperature sensors, IoT devices, GPS tracking, thermal packaging. | Inventory management software, barcodes, RFID, ERP systems. |

| Regulatory Compliance | FDA, WHO guidelines for cold chain products. | Industry standards, financial regulations related to inventory valuation. |

| Impact on Supply Chain | Ensures product safety and efficacy from origin to end-user. | Optimizes stock availability, reduces carrying costs. |

Which is better?

Cold chain management ensures the integrity of temperature-sensitive products like pharmaceuticals and perishable foods by maintaining strict temperature controls throughout the supply chain, reducing spoilage and ensuring regulatory compliance. Inventory management optimizes stock levels, demand forecasting, and order fulfillment to minimize holding costs and prevent stockouts, enhancing overall operational efficiency. While inventory management provides broad control over stock resources, cold chain management is critical for industries requiring specialized handling to preserve product quality and safety.

Connection

Cold chain management ensures temperature-sensitive products remain within specified conditions throughout storage and transportation, directly impacting inventory quality and shelf life. Inventory management relies on accurate tracking and monitoring of these conditions to prevent spoilage, reduce waste, and maintain optimal stock levels. The integration of cold chain data with inventory systems enhances real-time decision-making and improves supply chain efficiency.

Key Terms

**Inventory Management:**

Inventory management involves the systematic control of stock levels, ensuring optimal quantities to meet demand without overstocking or stockouts. This process includes tracking, ordering, storing, and forecasting inventory to enhance operational efficiency and reduce costs. Explore more to understand how advanced inventory management solutions can transform your supply chain performance.

Stock Keeping Unit (SKU)

Inventory management optimizes Stock Keeping Unit (SKU) tracking by ensuring accurate availability and efficient replenishment across warehouses and stores. Cold chain management extends SKU oversight by maintaining strict temperature control for perishable items, preventing spoilage and ensuring compliance with safety standards. Discover detailed strategies to enhance SKU precision in both inventory and cold chain systems.

Reorder Point

Reorder point in inventory management is the specific stock level at which new orders are triggered to replenish inventory before it runs out, ensuring continuous supply and avoiding stockouts. In cold chain management, reorder points must account for factors like temperature-sensitive product shelf life, spoilage risk, and longer lead times due to specialized transportation, making the calculation more complex and critical for maintaining product integrity. Explore how optimizing reorder points can improve efficiency and reduce waste in both inventory and cold chain systems.

Source and External Links

What Is Inventory Management? Benefits, Types, & Process - Inventory management involves tracking and controlling the flow of goods through steps such as demand planning, ordering, delivery, storage, sales fulfillment, reviewing/reporting, and replenishment to optimize stock levels and supply chain efficiency.

Inventory Management: How it Works and Tools (2025) - Key inventory management techniques include economic order quantity (EOQ), demand planning, inventory counts, FIFO/LIFO methods, RFID, barcodes, safety stock alerts, and just-in-time strategies to balance stock levels and reduce costs.

Inventory Management Guide + Methods & Examples - Inventory management methods range from spreadsheets and automated systems to ERP and multichannel management, helping businesses track and organize inventory in real-time across multiple sales platforms and warehouses.

dowidth.com

dowidth.com