Middle mile automation streamlines the transportation and handling of goods between suppliers and distribution centers, significantly enhancing efficiency through robotics and real-time tracking systems. Cross-docking reduces storage time by directly transferring incoming shipments to outbound trucks, minimizing inventory and accelerating delivery cycles. Discover how integrating middle mile automation with cross-docking can revolutionize your supply chain operations.

Why it is important

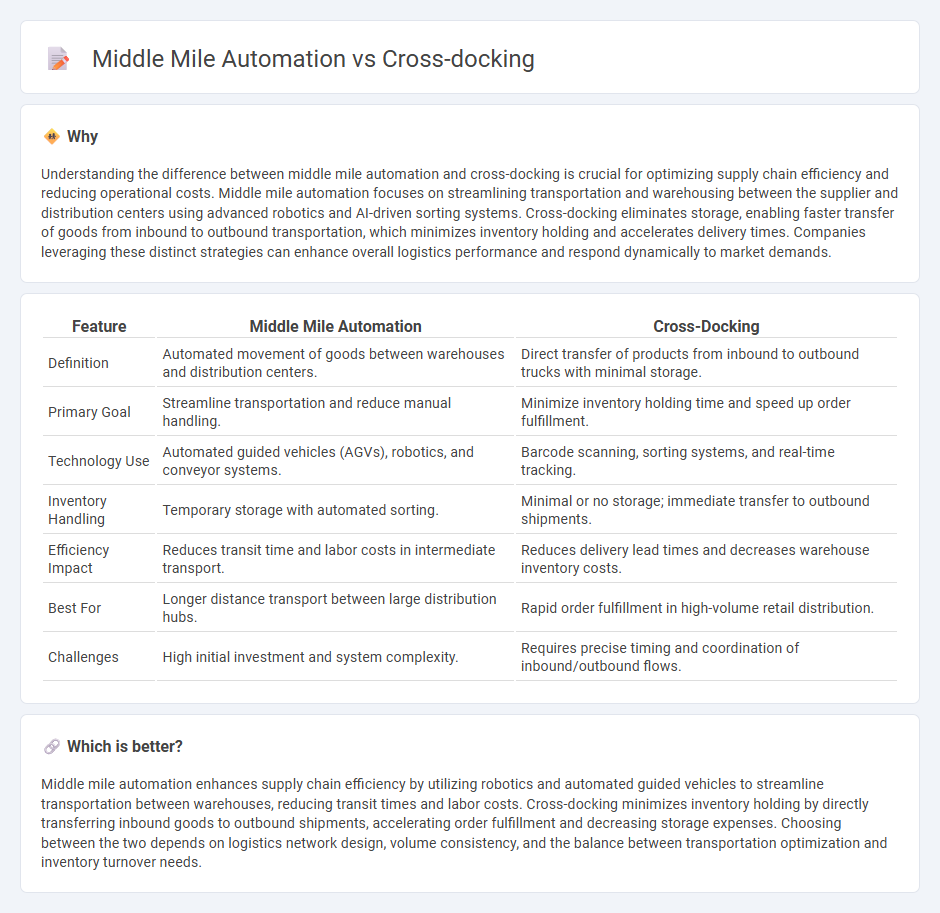

Understanding the difference between middle mile automation and cross-docking is crucial for optimizing supply chain efficiency and reducing operational costs. Middle mile automation focuses on streamlining transportation and warehousing between the supplier and distribution centers using advanced robotics and AI-driven sorting systems. Cross-docking eliminates storage, enabling faster transfer of goods from inbound to outbound transportation, which minimizes inventory holding and accelerates delivery times. Companies leveraging these distinct strategies can enhance overall logistics performance and respond dynamically to market demands.

Comparison Table

| Feature | Middle Mile Automation | Cross-Docking |

|---|---|---|

| Definition | Automated movement of goods between warehouses and distribution centers. | Direct transfer of products from inbound to outbound trucks with minimal storage. |

| Primary Goal | Streamline transportation and reduce manual handling. | Minimize inventory holding time and speed up order fulfillment. |

| Technology Use | Automated guided vehicles (AGVs), robotics, and conveyor systems. | Barcode scanning, sorting systems, and real-time tracking. |

| Inventory Handling | Temporary storage with automated sorting. | Minimal or no storage; immediate transfer to outbound shipments. |

| Efficiency Impact | Reduces transit time and labor costs in intermediate transport. | Reduces delivery lead times and decreases warehouse inventory costs. |

| Best For | Longer distance transport between large distribution hubs. | Rapid order fulfillment in high-volume retail distribution. |

| Challenges | High initial investment and system complexity. | Requires precise timing and coordination of inbound/outbound flows. |

Which is better?

Middle mile automation enhances supply chain efficiency by utilizing robotics and automated guided vehicles to streamline transportation between warehouses, reducing transit times and labor costs. Cross-docking minimizes inventory holding by directly transferring inbound goods to outbound shipments, accelerating order fulfillment and decreasing storage expenses. Choosing between the two depends on logistics network design, volume consistency, and the balance between transportation optimization and inventory turnover needs.

Connection

Middle mile automation enhances efficiency by integrating automated sorting and handling technologies that streamline goods movement between distribution centers. Cross-docking complements this process by minimizing storage time through direct transfer of shipments from inbound to outbound transportation, reducing dwell times. Together, these methods optimize inventory flow, lower operational costs, and accelerate delivery cycles in logistics management.

Key Terms

Transshipment

Cross-docking streamlines the transshipment process by minimizing storage time, enabling rapid transfer of goods from inbound to outbound transportation. Middle mile automation enhances efficiency through technologies like automated sorting systems and real-time tracking, reducing handling errors and transit times during transshipment. Explore how these strategies optimize supply chain operations and improve delivery speed.

Sortation

Cross-docking minimizes storage time by directly transferring inbound goods to outbound shipments, enhancing efficiency in supply chains. Middle mile automation, particularly through advanced sortation systems, streamlines the movement of goods between distribution centers, reducing handling errors and accelerating processing times. Explore the benefits of integrating sortation technology in middle mile operations to optimize logistics performance.

Autonomous Vehicles

Cross-docking streamlines logistics by transferring goods directly from inbound to outbound vehicles, reducing storage time and accelerating delivery. Middle mile automation leverages Autonomous Vehicles (AVs) to optimize transportation between distribution centers, enhancing efficiency, reducing labor costs, and minimizing human error. Explore how integrating AV technology transforms both cross-docking and middle mile operations for smarter supply chain management.

Source and External Links

Cross Docking: Definition, History, and Process - Inbound Logistics - Cross docking is a shipping method that transfers goods directly from inbound to outbound transportation with minimal storage time; key methods include continuous cross docking, consolidation, and de-consolidation aimed at increasing efficiency and reducing costs.

What Is Cross-Docking? Definition, Types & Advantages - NetSuite - Cross-docking is a supply chain strategy where goods are transferred directly from incoming to outgoing vehicles at a logistics facility to speed up delivery, reduce storage needs, and cut transportation and labor costs.

Understanding cross-docking: A comprehensive guide - Maersk - Cross-docking minimizes storage by rapidly moving products from suppliers to customers, with types including pre-distribution, post-distribution, continuous, consolidation, and deconsolidation, each suited for different industry needs like retail, manufacturing, and e-commerce.

dowidth.com

dowidth.com