Pick and pack is a logistics process where individual products are selected from inventory and packed for shipment, optimizing order accuracy and customer satisfaction. Milk run is a transportation strategy that consolidates multiple deliveries or pickups into a single route, reducing costs and improving efficiency. Explore how these methods can enhance your supply chain performance.

Why it is important

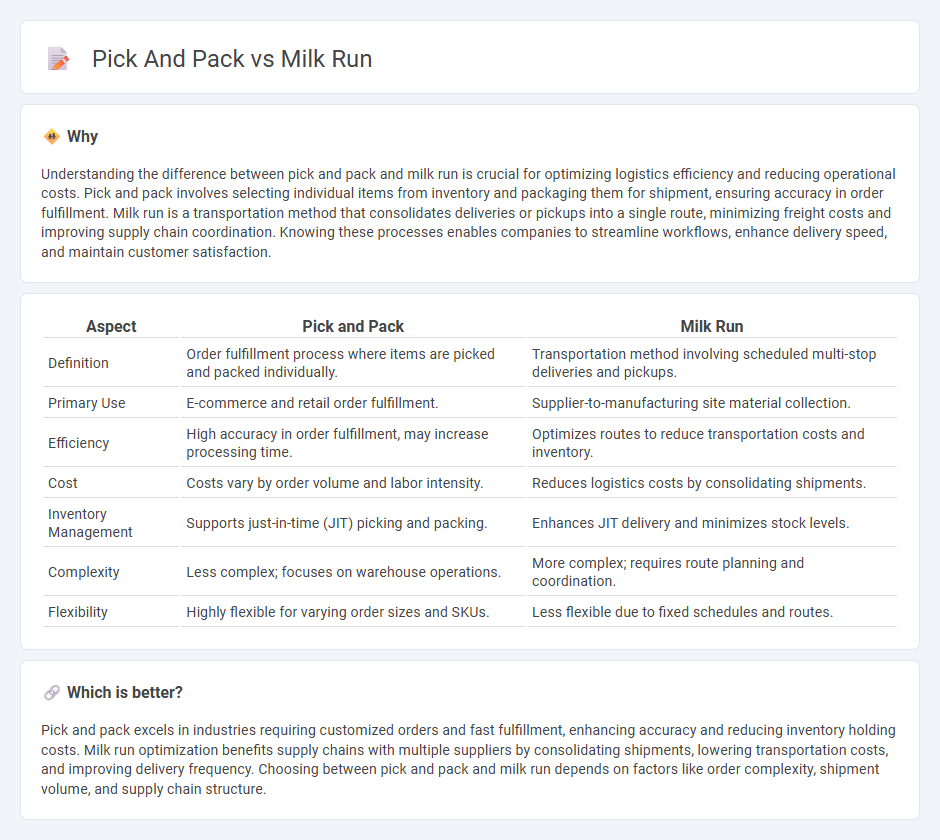

Understanding the difference between pick and pack and milk run is crucial for optimizing logistics efficiency and reducing operational costs. Pick and pack involves selecting individual items from inventory and packaging them for shipment, ensuring accuracy in order fulfillment. Milk run is a transportation method that consolidates deliveries or pickups into a single route, minimizing freight costs and improving supply chain coordination. Knowing these processes enables companies to streamline workflows, enhance delivery speed, and maintain customer satisfaction.

Comparison Table

| Aspect | Pick and Pack | Milk Run |

|---|---|---|

| Definition | Order fulfillment process where items are picked and packed individually. | Transportation method involving scheduled multi-stop deliveries and pickups. |

| Primary Use | E-commerce and retail order fulfillment. | Supplier-to-manufacturing site material collection. |

| Efficiency | High accuracy in order fulfillment, may increase processing time. | Optimizes routes to reduce transportation costs and inventory. |

| Cost | Costs vary by order volume and labor intensity. | Reduces logistics costs by consolidating shipments. |

| Inventory Management | Supports just-in-time (JIT) picking and packing. | Enhances JIT delivery and minimizes stock levels. |

| Complexity | Less complex; focuses on warehouse operations. | More complex; requires route planning and coordination. |

| Flexibility | Highly flexible for varying order sizes and SKUs. | Less flexible due to fixed schedules and routes. |

Which is better?

Pick and pack excels in industries requiring customized orders and fast fulfillment, enhancing accuracy and reducing inventory holding costs. Milk run optimization benefits supply chains with multiple suppliers by consolidating shipments, lowering transportation costs, and improving delivery frequency. Choosing between pick and pack and milk run depends on factors like order complexity, shipment volume, and supply chain structure.

Connection

Pick and pack and milk run are interconnected logistics processes aimed at enhancing supply chain efficiency by reducing handling time and transportation costs. Pick and pack involves selecting ordered products from inventory and preparing them for shipment, while milk run optimizes delivery by consolidating multiple pickups from suppliers into a single trip. Together, these strategies streamline order fulfillment, minimize inventory holding, and improve overall transportation management within supply chain operations.

Key Terms

Route Optimization

Milk run route optimization streamlines multiple deliveries or pickups into one loop, reducing transportation costs and improving inventory management by consolidating shipments. Pick and pack route optimization focuses on sequencing orders within warehouses to minimize travel time and enhance order fulfillment accuracy. Explore detailed strategies to optimize both milk run and pick and pack processes for efficient supply chain management.

Consolidation

Milk run logistics optimizes consolidation by collecting small shipments from multiple suppliers into a single, efficient delivery, minimizing transportation costs and reducing environmental impact. Pick and pack operations consolidate products by selecting and packaging items based on individual customer orders, streamlining order fulfillment and inventory management. Explore detailed strategies to enhance supply chain efficiency through milk run and pick and pack consolidation methods.

Order Fulfillment

Milk run optimizes order fulfillment by consolidating multiple supplier shipments into a single delivery route, reducing transportation costs and ensuring timely replenishment. Pick and pack focuses on accurately selecting and packaging individual customer orders, enhancing order accuracy and speed in distribution centers. Explore detailed strategies to improve your order fulfillment efficiency with milk run and pick and pack methods.

Source and External Links

Milk Run in Logistics: Meaning, Pros, & Cons - ShipBob - The milk run is a logistics delivery method where one vehicle collects goods from multiple suppliers and transports them in a single trip to a single customer, originally inspired by milk delivery routes to keep supply fresh and prevent overstocking.

What is a milk run in logistics? | Red Stag Fulfillment - A milk run in logistics is a route-based process for picking up and delivering items at multiple stops on a predefined path, designed to optimize inventory replenishment and reduce costs by minimizing partial shipments and overstock.

Milk Run - Lean Enterprise Institute - Milk run is a lean logistics method that speeds material flow by routing vehicles to make multiple pickups and drop-offs across facilities, reducing inventory levels and improving response times.

dowidth.com

dowidth.com