Reverse logistics focuses on the efficient return, recycling, or disposal of products from customers back to suppliers, optimizing sustainability and cost management. Cross-docking minimizes storage time by directly transferring goods from inbound to outbound transportation, enhancing speed and reducing warehousing expenses. Explore the key differences and benefits of these logistics strategies to streamline your supply chain operations.

Why it is important

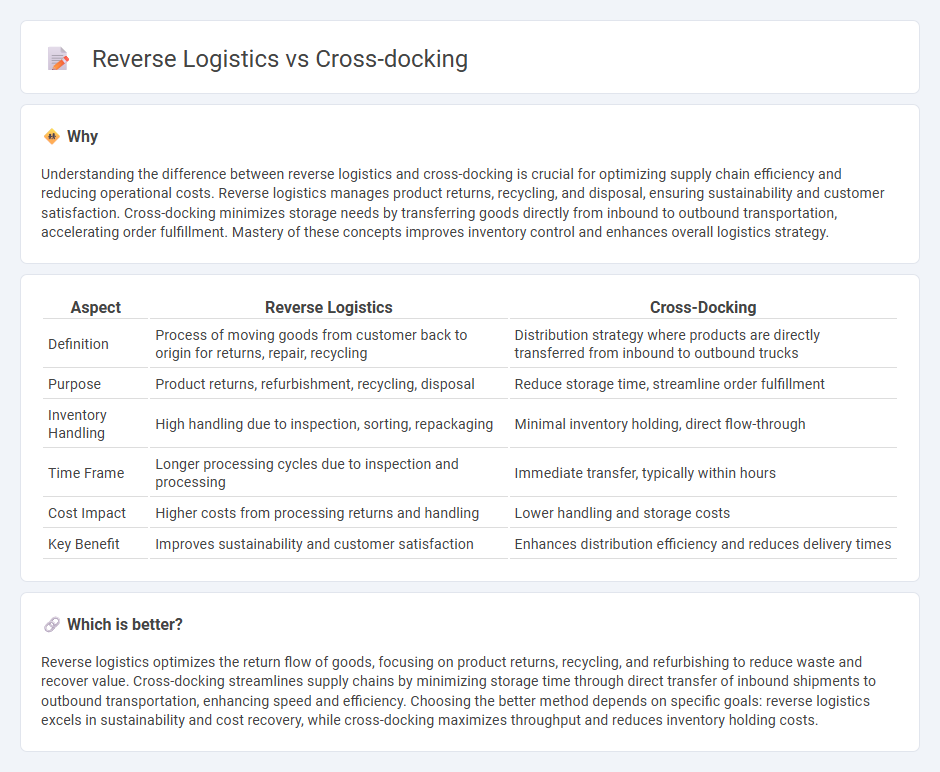

Understanding the difference between reverse logistics and cross-docking is crucial for optimizing supply chain efficiency and reducing operational costs. Reverse logistics manages product returns, recycling, and disposal, ensuring sustainability and customer satisfaction. Cross-docking minimizes storage needs by transferring goods directly from inbound to outbound transportation, accelerating order fulfillment. Mastery of these concepts improves inventory control and enhances overall logistics strategy.

Comparison Table

| Aspect | Reverse Logistics | Cross-Docking |

|---|---|---|

| Definition | Process of moving goods from customer back to origin for returns, repair, recycling | Distribution strategy where products are directly transferred from inbound to outbound trucks |

| Purpose | Product returns, refurbishment, recycling, disposal | Reduce storage time, streamline order fulfillment |

| Inventory Handling | High handling due to inspection, sorting, repackaging | Minimal inventory holding, direct flow-through |

| Time Frame | Longer processing cycles due to inspection and processing | Immediate transfer, typically within hours |

| Cost Impact | Higher costs from processing returns and handling | Lower handling and storage costs |

| Key Benefit | Improves sustainability and customer satisfaction | Enhances distribution efficiency and reduces delivery times |

Which is better?

Reverse logistics optimizes the return flow of goods, focusing on product returns, recycling, and refurbishing to reduce waste and recover value. Cross-docking streamlines supply chains by minimizing storage time through direct transfer of inbound shipments to outbound transportation, enhancing speed and efficiency. Choosing the better method depends on specific goals: reverse logistics excels in sustainability and cost recovery, while cross-docking maximizes throughput and reduces inventory holding costs.

Connection

Reverse logistics and cross-docking are connected through their roles in streamlining supply chain efficiency and reducing operational costs. Reverse logistics focuses on the return flow of goods from customers to warehouses, enhancing product lifecycle management, while cross-docking facilitates rapid transfer of inbound shipments directly to outbound transportation, minimizing storage time. Integrating both processes improves inventory turnover rates and accelerates the handling of returned or redistributed products in logistics networks.

Key Terms

Transshipment

Cross-docking optimizes supply chain efficiency by transferring products directly from inbound to outbound transportation with minimal storage, reducing handling time and inventory costs. Reverse logistics involves the management of product returns, repairs, remanufacturing, and recycling, often necessitating complex transshipment processes to route items back through the supply chain. Explore deeper insights into how transshipment enhances operational flexibility in both cross-docking and reverse logistics strategies.

Returns Management

Cross-docking streamlines returns management by minimizing storage time and swiftly redirecting returned goods to appropriate destinations, reducing handling costs and improving inventory flow. Reverse logistics focuses on the comprehensive process of returning products from customers back to manufacturers or warehouses for resale, recycling, or disposal. Explore detailed strategies and best practices to optimize your returns management process effectively.

Inventory Flow

Cross-docking minimizes inventory holding by directly transferring products from inbound to outbound transportation, accelerating inventory flow and reducing storage costs. Reverse logistics involves managing returns and recycling, which introduces complexity and slows inventory flow due to inspections, sorting, and reprocessing. Explore more about optimizing inventory flow through cross-docking and reverse logistics strategies.

Source and External Links

Cross Docking: Definition, History, and Process - Inbound Logistics - Cross docking is a shipping method transferring goods directly from an inbound to an outbound transportation mode with minimal storage, using methods like continuous cross docking, consolidation, and de-consolidation to optimize efficiency.

What Is Cross-Docking? Definition, Types & Advantages - NetSuite - Cross-docking speeds product delivery by unloading from inbound vehicles and reloading onto outbound vehicles with little to no warehouse storage, reducing costs and enhancing supply chain efficiency for various industries.

Understanding cross-docking: A comprehensive guide - Maersk - Cross-docking involves minimal storage time by transferring products directly from suppliers to customers, categorized into types like pre-distribution, post-distribution, continuous, consolidation, and deconsolidation to meet different logistical needs.

dowidth.com

dowidth.com