Silent delivery minimizes noise and disruption in supply chain operations by scheduling shipments during off-peak hours, enhancing efficiency and workplace safety. Milk run logistics consolidates multiple deliveries into a single route, reducing transportation costs and carbon emissions while improving inventory management. Explore the advantages and applications of silent delivery versus milk run to optimize your logistics strategy.

Why it is important

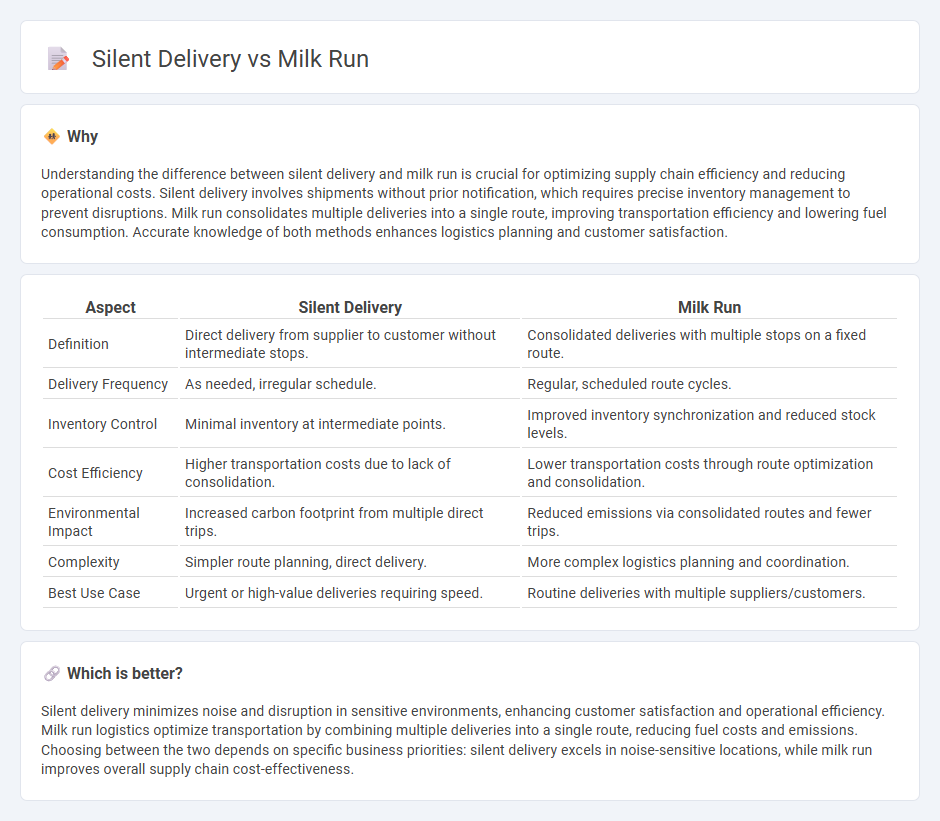

Understanding the difference between silent delivery and milk run is crucial for optimizing supply chain efficiency and reducing operational costs. Silent delivery involves shipments without prior notification, which requires precise inventory management to prevent disruptions. Milk run consolidates multiple deliveries into a single route, improving transportation efficiency and lowering fuel consumption. Accurate knowledge of both methods enhances logistics planning and customer satisfaction.

Comparison Table

| Aspect | Silent Delivery | Milk Run |

|---|---|---|

| Definition | Direct delivery from supplier to customer without intermediate stops. | Consolidated deliveries with multiple stops on a fixed route. |

| Delivery Frequency | As needed, irregular schedule. | Regular, scheduled route cycles. |

| Inventory Control | Minimal inventory at intermediate points. | Improved inventory synchronization and reduced stock levels. |

| Cost Efficiency | Higher transportation costs due to lack of consolidation. | Lower transportation costs through route optimization and consolidation. |

| Environmental Impact | Increased carbon footprint from multiple direct trips. | Reduced emissions via consolidated routes and fewer trips. |

| Complexity | Simpler route planning, direct delivery. | More complex logistics planning and coordination. |

| Best Use Case | Urgent or high-value deliveries requiring speed. | Routine deliveries with multiple suppliers/customers. |

Which is better?

Silent delivery minimizes noise and disruption in sensitive environments, enhancing customer satisfaction and operational efficiency. Milk run logistics optimize transportation by combining multiple deliveries into a single route, reducing fuel costs and emissions. Choosing between the two depends on specific business priorities: silent delivery excels in noise-sensitive locations, while milk run improves overall supply chain cost-effectiveness.

Connection

Silent delivery and milk run logistics enhance supply chain efficiency by minimizing inventory buildup and reducing transportation costs. Silent delivery ensures just-in-time shipments without advanced notifications, while milk run consolidates multiple deliveries into a single route, optimizing vehicle utilization. Together, they streamline operations, improve supplier coordination, and reduce carbon footprint.

Key Terms

**Milk run:**

Milk run logistics optimize supply chain efficiency by consolidating multiple deliveries into a single, scheduled route, minimizing transportation costs and reducing carbon emissions. This approach enhances inventory management by ensuring timely, consistent replenishments and lowering safety stock levels. Discover how milk run strategies can transform your distribution operations and drive sustainability.

Route Optimization

Milk run and silent delivery both aim to enhance route optimization by reducing transportation costs and improving efficiency through strategic scheduling and load consolidation. Milk run routes are designed to collect and deliver materials from multiple suppliers in a single trip, minimizing travel distance and fuel consumption, while silent delivery emphasizes pre-planned, discreet drop-offs without direct recipient interaction, ensuring smoother logistics flow. Discover how optimizing these delivery methods can significantly boost supply chain performance and reduce operational costs.

Consolidated Pickup/Delivery

Milk run logistics optimize consolidated pickup and delivery by scheduling multiple stops in a single route to reduce transportation costs and improve supply chain efficiency. Silent delivery emphasizes discreet and direct consolidated delivery without prior notification, enhancing security and timely arrival for sensitive shipments. Explore detailed comparisons to identify the best approach for your supply chain consolidation needs.

Source and External Links

Milk Run in Logistics: Meaning, Pros, & Cons - The term "milk run" originates from the dairy industry where one tanker collected milk from various farms daily to deliver to a central processing firm, and in modern logistics, it refers to a delivery approach using one vehicle to pick up goods from various suppliers and transport them in a single shipment to one location for efficiency and inventory control.

What is a milk run in logistics? - A milk run is a pre-defined delivery or pickup route that involves traveling short routes to pick up or drop off items at multiple stops, optimizing inventory replenishment and reducing overstock in lean manufacturing and warehouse operations.

What Is a Milk Run? Logistics Glossary - Milk run is a delivery method used to transport mixed loads from various suppliers to one customer or a route with many stops, originating from WWII dairy industry practices where milk carriers both delivered milk and collected empty bottles.

dowidth.com

dowidth.com