Urban consolidation centres streamline last-mile deliveries by consolidating shipments in a central urban location to reduce traffic congestion and emissions. Cross-docking minimizes storage time by transferring goods directly from inbound to outbound transportation, enhancing supply chain efficiency. Discover how these logistics strategies can optimize your delivery network.

Why it is important

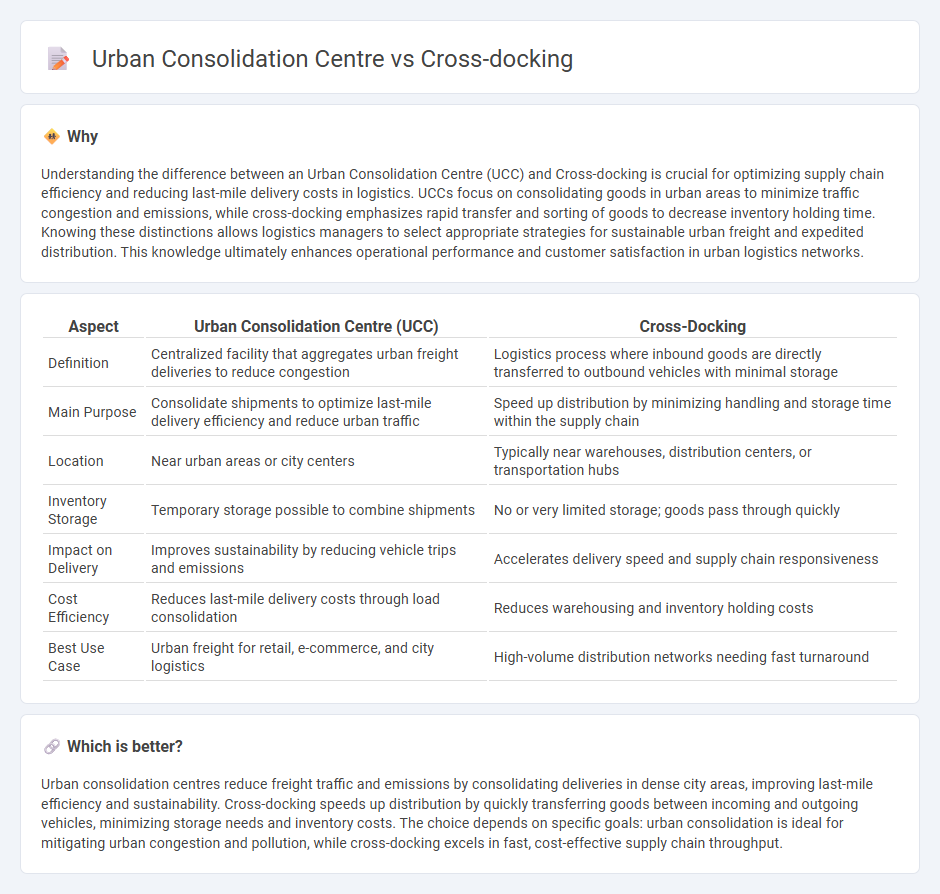

Understanding the difference between an Urban Consolidation Centre (UCC) and Cross-docking is crucial for optimizing supply chain efficiency and reducing last-mile delivery costs in logistics. UCCs focus on consolidating goods in urban areas to minimize traffic congestion and emissions, while cross-docking emphasizes rapid transfer and sorting of goods to decrease inventory holding time. Knowing these distinctions allows logistics managers to select appropriate strategies for sustainable urban freight and expedited distribution. This knowledge ultimately enhances operational performance and customer satisfaction in urban logistics networks.

Comparison Table

| Aspect | Urban Consolidation Centre (UCC) | Cross-Docking |

|---|---|---|

| Definition | Centralized facility that aggregates urban freight deliveries to reduce congestion | Logistics process where inbound goods are directly transferred to outbound vehicles with minimal storage |

| Main Purpose | Consolidate shipments to optimize last-mile delivery efficiency and reduce urban traffic | Speed up distribution by minimizing handling and storage time within the supply chain |

| Location | Near urban areas or city centers | Typically near warehouses, distribution centers, or transportation hubs |

| Inventory Storage | Temporary storage possible to combine shipments | No or very limited storage; goods pass through quickly |

| Impact on Delivery | Improves sustainability by reducing vehicle trips and emissions | Accelerates delivery speed and supply chain responsiveness |

| Cost Efficiency | Reduces last-mile delivery costs through load consolidation | Reduces warehousing and inventory holding costs |

| Best Use Case | Urban freight for retail, e-commerce, and city logistics | High-volume distribution networks needing fast turnaround |

Which is better?

Urban consolidation centres reduce freight traffic and emissions by consolidating deliveries in dense city areas, improving last-mile efficiency and sustainability. Cross-docking speeds up distribution by quickly transferring goods between incoming and outgoing vehicles, minimizing storage needs and inventory costs. The choice depends on specific goals: urban consolidation is ideal for mitigating urban congestion and pollution, while cross-docking excels in fast, cost-effective supply chain throughput.

Connection

Urban consolidation centres streamline last-mile logistics by consolidating shipments from multiple suppliers into fewer deliveries, reducing traffic congestion and emissions in densely populated areas. Cross-docking facilitates this process by enabling rapid transfer of goods from inbound to outbound transport without long-term storage, accelerating the flow of consolidated shipments. Both strategies optimize urban supply chains by minimizing delivery times and enhancing distribution efficiency within city environments.

Key Terms

Transshipment point

Cross-docking streamlines logistics by minimizing storage time at the transshipment point, enabling direct transfer of goods from inbound to outbound transport. Urban consolidation centres optimize last-mile delivery by aggregating shipments at a central transshipment point, reducing urban congestion and emissions. Discover how these transshipment strategies enhance supply chain efficiency and sustainability.

Last-mile delivery

Cross-docking significantly reduces storage time by directly transferring goods from inbound to outbound transportation, optimizing last-mile delivery efficiency. Urban consolidation centres centralize shipments within city logistics, lowering delivery frequency and emissions by combining parcels for final distribution. Explore the latest strategies in last-mile delivery to enhance urban freight management and sustainability.

Inventory holding

Cross-docking minimizes inventory holding by transferring goods directly from inbound to outbound transportation without storage, significantly reducing warehousing costs and delivery times. Urban consolidation centres strategically consolidate shipments from multiple suppliers, enabling lower inventory levels at individual stores but requiring a small buffer stock to manage demand variability. Explore how these logistics strategies impact inventory management efficiency and operational costs in urban supply chains.

Source and External Links

Cross Docking: Definition, History, and Process - Cross-docking is a shipping method transferring goods directly from inbound to outbound transportation with minimal storage, using methods like continuous flow, consolidation, and deconsolidation to optimize efficiency and reduce costs.

What Is Cross-Docking? Definition, Types & Advantages - Cross-docking is a supply chain technique where goods move directly from inbound to outbound trucks with little or no warehouse storage, speeding delivery, reducing costs, and improving inventory control across industries like retail and ecommerce.

Understanding cross-docking: A comprehensive guide - Cross-docking entails minimal storage at a terminal by directly transferring products from suppliers to customers, featuring types like pre-distribution, post-distribution, continuous, consolidation, and deconsolidation tailored to different logistical needs.

dowidth.com

dowidth.com