Milk run delivery optimizes transportation by consolidating multiple shipments into a single, efficient route, reducing fuel consumption and improving delivery frequency. Cross-docking minimizes inventory holding by directly transferring goods from inbound to outbound transportation, speeding up the distribution process and lowering storage costs. Explore more to understand which logistics strategy best suits your supply chain needs.

Why it is important

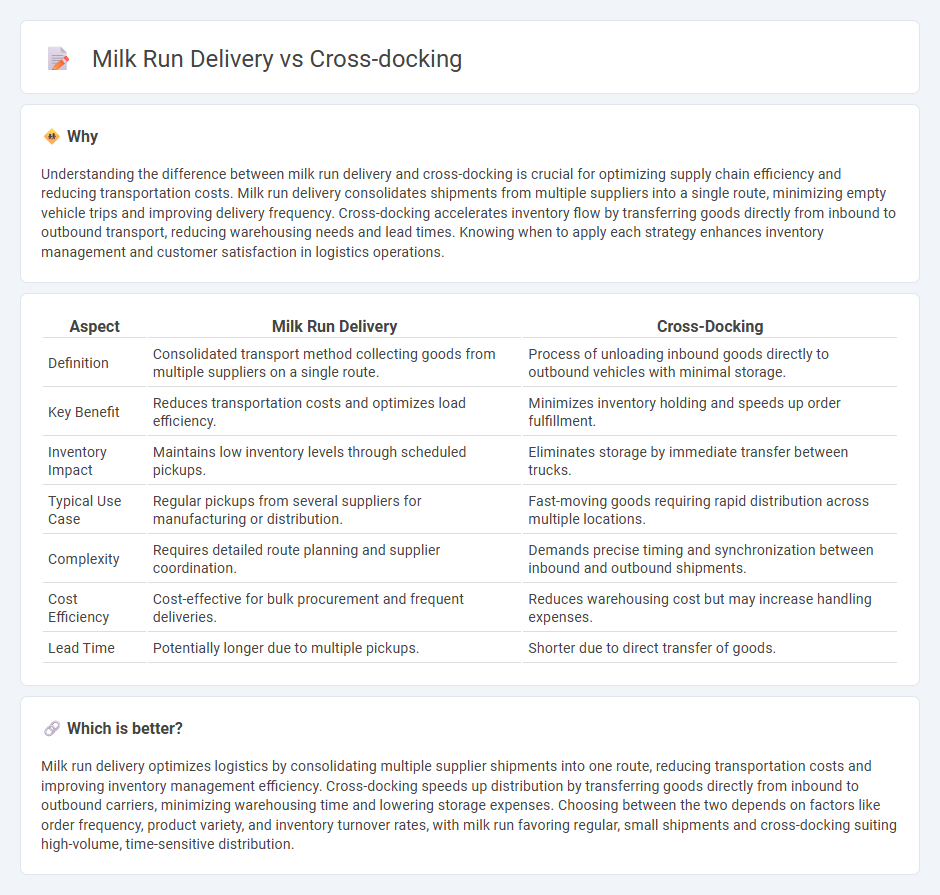

Understanding the difference between milk run delivery and cross-docking is crucial for optimizing supply chain efficiency and reducing transportation costs. Milk run delivery consolidates shipments from multiple suppliers into a single route, minimizing empty vehicle trips and improving delivery frequency. Cross-docking accelerates inventory flow by transferring goods directly from inbound to outbound transport, reducing warehousing needs and lead times. Knowing when to apply each strategy enhances inventory management and customer satisfaction in logistics operations.

Comparison Table

| Aspect | Milk Run Delivery | Cross-Docking |

|---|---|---|

| Definition | Consolidated transport method collecting goods from multiple suppliers on a single route. | Process of unloading inbound goods directly to outbound vehicles with minimal storage. |

| Key Benefit | Reduces transportation costs and optimizes load efficiency. | Minimizes inventory holding and speeds up order fulfillment. |

| Inventory Impact | Maintains low inventory levels through scheduled pickups. | Eliminates storage by immediate transfer between trucks. |

| Typical Use Case | Regular pickups from several suppliers for manufacturing or distribution. | Fast-moving goods requiring rapid distribution across multiple locations. |

| Complexity | Requires detailed route planning and supplier coordination. | Demands precise timing and synchronization between inbound and outbound shipments. |

| Cost Efficiency | Cost-effective for bulk procurement and frequent deliveries. | Reduces warehousing cost but may increase handling expenses. |

| Lead Time | Potentially longer due to multiple pickups. | Shorter due to direct transfer of goods. |

Which is better?

Milk run delivery optimizes logistics by consolidating multiple supplier shipments into one route, reducing transportation costs and improving inventory management efficiency. Cross-docking speeds up distribution by transferring goods directly from inbound to outbound carriers, minimizing warehousing time and lowering storage expenses. Choosing between the two depends on factors like order frequency, product variety, and inventory turnover rates, with milk run favoring regular, small shipments and cross-docking suiting high-volume, time-sensitive distribution.

Connection

Milk run delivery optimizes supply chain efficiency by scheduling frequent, consolidated pickups from multiple suppliers, reducing transportation costs and lead times. Cross-docking complements this approach by enabling rapid transfer of goods from inbound to outbound transportation without long-term storage, minimizing inventory holding. Together, milk run delivery and cross-docking enhance logistics performance through streamlined, cost-effective material flow.

Key Terms

Distribution Center

Cross-docking minimizes inventory holding by directly transferring goods from inbound to outbound shipments within Distribution Centers (DCs), streamlining order fulfillment and reducing storage costs. Milk run delivery optimizes routing to transport small quantities from multiple suppliers to a Distribution Center, enhancing load consolidation and reducing transportation expenses. Explore detailed strategies to improve Distribution Center efficiency through cross-docking and milk run delivery methods.

Consolidation

Cross-docking maximizes consolidation by transferring products directly from inbound to outbound transportation, minimizing storage time and boosting efficiency. Milk run delivery optimizes consolidation by systematically combining shipments from multiple suppliers into a single delivery route, reducing transportation costs and improving load utilization. Explore these strategies further to enhance your supply chain consolidation processes.

Route Optimization

Cross-docking minimizes storage time by directly transferring goods from inbound to outbound transportation, optimizing routes through centralized sorting and immediate dispatch. Milk run delivery enhances route efficiency by consolidating multiple deliveries or pickups into a single, planned circuit, reducing mileage and fuel costs. Explore detailed strategies to maximize route optimization benefits in your supply chain management.

Source and External Links

Cross Docking: Definition, History, and Process - Inbound Logistics - Cross docking is a shipping method transferring goods directly from one transportation mode to another with minimal or no storage time, and includes methods like continuous cross docking, consolidation, and de-consolidation to optimize efficiency and reduce costs.

What Is Cross-Docking? Definition, Types & Advantages - NetSuite - Cross-docking is a supply chain technique enabling quick transfer of goods between inbound and outbound trucks with little or no warehouse storage, improving delivery speed, reducing costs, and enhancing inventory control for retailers, manufacturers, and ecommerce companies.

Understanding cross-docking: A comprehensive guide - Maersk - Cross-docking minimizes storage by transferring products directly from suppliers to customers and includes types such as pre-distribution, post-distribution, and specialized forms tailored to retail, manufacturing, and ecommerce needs.

dowidth.com

dowidth.com