Milk run logistics streamline transportation by consolidating deliveries from multiple suppliers into a single trip, reducing fuel costs and inventory levels. Cross-docking minimizes storage time by directly transferring inbound goods to outbound transportation, accelerating order fulfillment and cutting warehousing expenses. Explore how these strategies optimize supply chain efficiency and reduce operational costs.

Why it is important

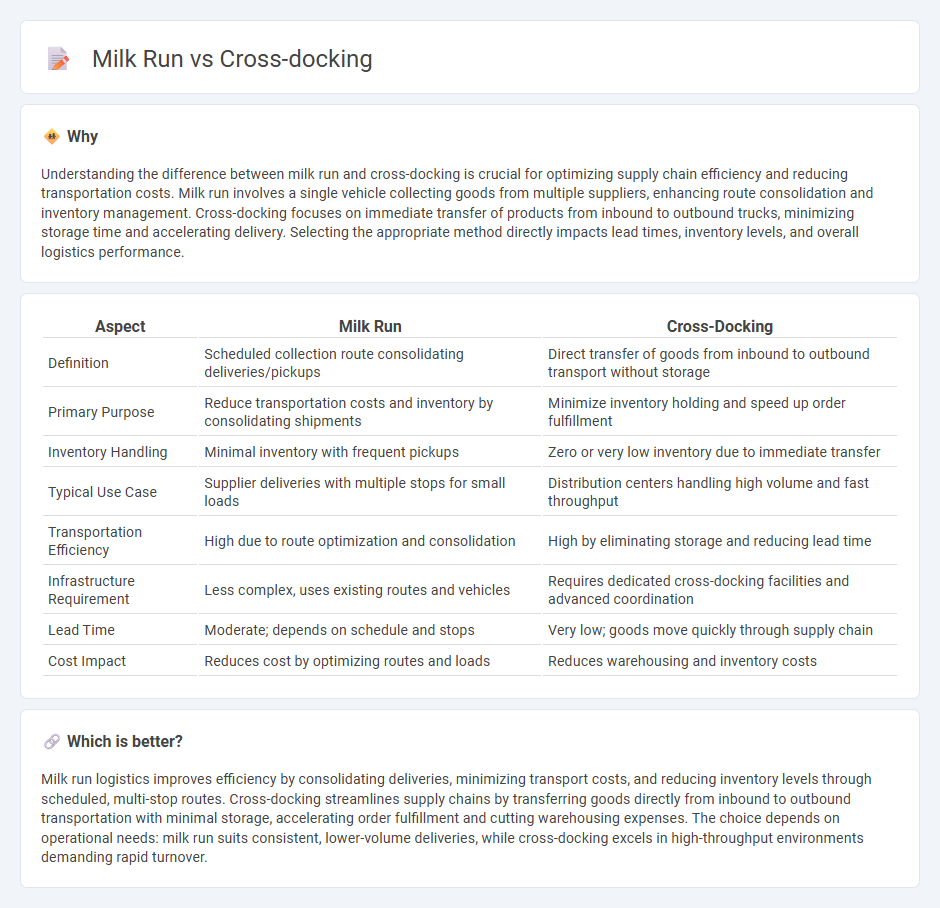

Understanding the difference between milk run and cross-docking is crucial for optimizing supply chain efficiency and reducing transportation costs. Milk run involves a single vehicle collecting goods from multiple suppliers, enhancing route consolidation and inventory management. Cross-docking focuses on immediate transfer of products from inbound to outbound trucks, minimizing storage time and accelerating delivery. Selecting the appropriate method directly impacts lead times, inventory levels, and overall logistics performance.

Comparison Table

| Aspect | Milk Run | Cross-Docking |

|---|---|---|

| Definition | Scheduled collection route consolidating deliveries/pickups | Direct transfer of goods from inbound to outbound transport without storage |

| Primary Purpose | Reduce transportation costs and inventory by consolidating shipments | Minimize inventory holding and speed up order fulfillment |

| Inventory Handling | Minimal inventory with frequent pickups | Zero or very low inventory due to immediate transfer |

| Typical Use Case | Supplier deliveries with multiple stops for small loads | Distribution centers handling high volume and fast throughput |

| Transportation Efficiency | High due to route optimization and consolidation | High by eliminating storage and reducing lead time |

| Infrastructure Requirement | Less complex, uses existing routes and vehicles | Requires dedicated cross-docking facilities and advanced coordination |

| Lead Time | Moderate; depends on schedule and stops | Very low; goods move quickly through supply chain |

| Cost Impact | Reduces cost by optimizing routes and loads | Reduces warehousing and inventory costs |

Which is better?

Milk run logistics improves efficiency by consolidating deliveries, minimizing transport costs, and reducing inventory levels through scheduled, multi-stop routes. Cross-docking streamlines supply chains by transferring goods directly from inbound to outbound transportation with minimal storage, accelerating order fulfillment and cutting warehousing expenses. The choice depends on operational needs: milk run suits consistent, lower-volume deliveries, while cross-docking excels in high-throughput environments demanding rapid turnover.

Connection

Milk run logistics and cross-docking are interconnected through their shared goal of minimizing inventory holding and streamlining supply chain efficiency. Milk run consolidates deliveries from multiple suppliers into a single vehicle route, reducing transportation costs and lead times. Cross-docking complements this by enabling direct transfer of goods from inbound to outbound transportation, eliminating storage and accelerating distribution.

Key Terms

Transfer Point

Cross-docking at the transfer point streamlines inventory flow by receiving goods directly from suppliers and quickly dispatching them to stores or production, minimizing storage time and reducing handling costs. Milk run optimizes transfer points by consolidating multiple deliveries within a region into a single, efficient route, enhancing transportation efficiency and lowering logistics expenses. Explore detailed strategies and benefits of transfer points in supply chain operations to improve your logistics network.

Consolidation

Cross-docking consolidates shipments by directly transferring goods from inbound to outbound transportation, minimizing storage time and accelerating delivery. Milk run optimizes consolidation by collecting smaller loads from multiple suppliers into a single trip, reducing transportation costs and improving efficiency. Explore detailed strategies to enhance your supply chain consolidation through cross-docking and milk run methods.

Route Optimization

Cross-docking minimizes storage time by directly transferring goods from inbound to outbound transportation, reducing handling and inventory costs through efficient route sequencing. Milk run systems optimize delivery by consolidating shipments with multiple stops along a scheduled route, enhancing load efficiency and reducing transportation expenses. Explore how advanced route optimization technologies improve supply chain performance in both cross-docking and milk run strategies.

Source and External Links

Cross Docking: Definition, History, and Process - Inbound Logistics - Cross docking is a shipping method transferring goods from one transportation mode to another with minimal or no storage, using methods like continuous cross docking for fast flow, consolidation for combining shipments, and de-consolidation for breaking large shipments into smaller ones .

What Is Cross-Docking? Definition, Types & Advantages - NetSuite - Cross-docking is a supply chain technique that speeds delivery and reduces costs by transferring goods directly from inbound to outbound vehicles at a logistics facility with little or no warehouse storage involved .

Understanding cross-docking: A comprehensive guide - Maersk - Cross-docking involves minimal storage by directly transferring goods from suppliers to customers, including types like pre-distribution and post-distribution, and specialised forms for retail, manufacturing, and e-commerce .

dowidth.com

dowidth.com