Predictive fleet maintenance leverages real-time data and advanced analytics to forecast vehicle repairs, reducing downtime and optimizing operational efficiency in logistics. Inventory management focuses on tracking stock levels, demand forecasting, and supply chain coordination to ensure timely product availability and minimize storage costs. Explore the advantages of combining predictive maintenance with inventory strategies to enhance overall logistics performance.

Why it is important

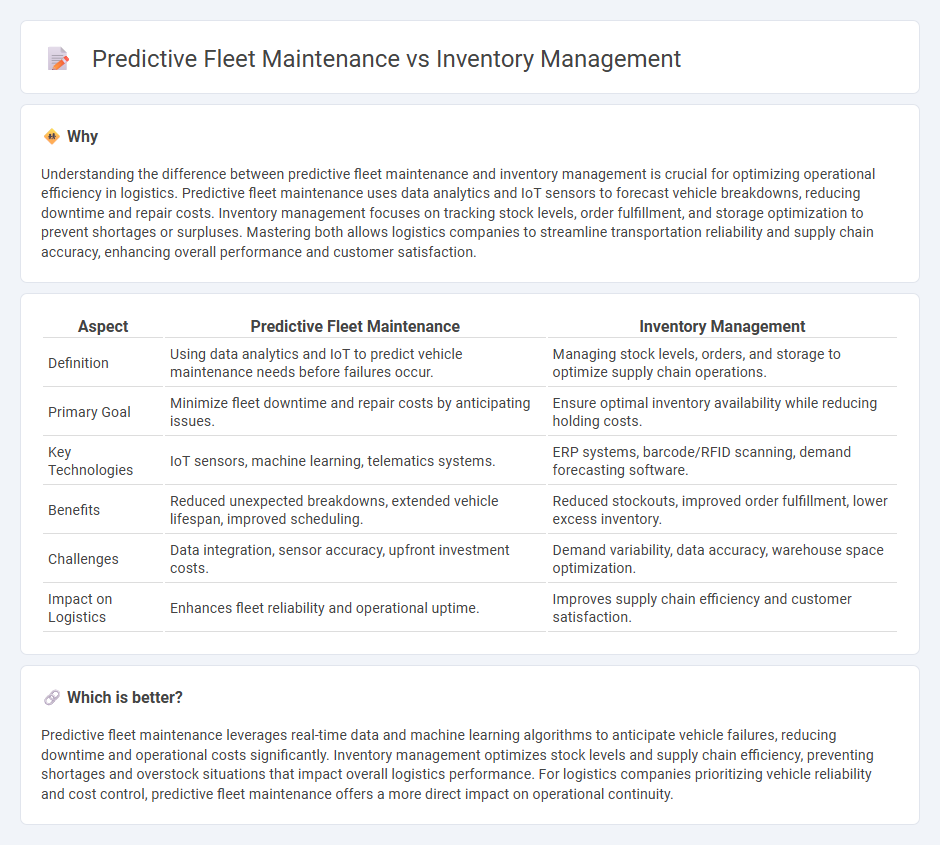

Understanding the difference between predictive fleet maintenance and inventory management is crucial for optimizing operational efficiency in logistics. Predictive fleet maintenance uses data analytics and IoT sensors to forecast vehicle breakdowns, reducing downtime and repair costs. Inventory management focuses on tracking stock levels, order fulfillment, and storage optimization to prevent shortages or surpluses. Mastering both allows logistics companies to streamline transportation reliability and supply chain accuracy, enhancing overall performance and customer satisfaction.

Comparison Table

| Aspect | Predictive Fleet Maintenance | Inventory Management |

|---|---|---|

| Definition | Using data analytics and IoT to predict vehicle maintenance needs before failures occur. | Managing stock levels, orders, and storage to optimize supply chain operations. |

| Primary Goal | Minimize fleet downtime and repair costs by anticipating issues. | Ensure optimal inventory availability while reducing holding costs. |

| Key Technologies | IoT sensors, machine learning, telematics systems. | ERP systems, barcode/RFID scanning, demand forecasting software. |

| Benefits | Reduced unexpected breakdowns, extended vehicle lifespan, improved scheduling. | Reduced stockouts, improved order fulfillment, lower excess inventory. |

| Challenges | Data integration, sensor accuracy, upfront investment costs. | Demand variability, data accuracy, warehouse space optimization. |

| Impact on Logistics | Enhances fleet reliability and operational uptime. | Improves supply chain efficiency and customer satisfaction. |

Which is better?

Predictive fleet maintenance leverages real-time data and machine learning algorithms to anticipate vehicle failures, reducing downtime and operational costs significantly. Inventory management optimizes stock levels and supply chain efficiency, preventing shortages and overstock situations that impact overall logistics performance. For logistics companies prioritizing vehicle reliability and cost control, predictive fleet maintenance offers a more direct impact on operational continuity.

Connection

Predictive fleet maintenance relies on real-time data analytics and IoT sensors to forecast vehicle breakdowns, which directly influences inventory management by optimizing spare parts stock levels. Integration of predictive models reduces downtime and excess inventory, ensuring efficient resource allocation and cost savings. Synchronizing these processes enhances operational efficiency and supports proactive decision-making in logistics management.

Key Terms

**Inventory Management:**

Inventory management optimizes the availability of spare parts and supplies, reducing downtime and operational costs in fleet maintenance. Efficient inventory tracking and automated reorder systems ensure critical components are stocked, preventing delays caused by part shortages. Explore how advanced inventory management solutions streamline fleet operations and enhance predictive maintenance efficiency.

Stock Keeping Unit (SKU)

Inventory management centers on optimizing Stock Keeping Unit (SKU) levels to ensure accurate demand forecasting, reduce stockouts, and minimize holding costs. Predictive fleet maintenance uses real-time data and machine learning algorithms to anticipate vehicle failures, indirectly affecting SKU availability by preventing supply chain disruptions. Discover how integrating SKU-centric inventory strategies with predictive fleet maintenance can enhance overall operational efficiency.

Reorder Point (ROP)

Reorder Point (ROP) is a critical metric in inventory management that triggers replenishment orders when stock falls to a predetermined level, ensuring parts availability without overstocking. In predictive fleet maintenance, ROP leverages real-time data and predictive analytics to forecast part usage and condition, optimizing maintenance scheduling and minimizing downtime. Explore how integrating ROP in both domains enhances operational efficiency and reduces costs.

Source and External Links

What Is Inventory Management? Benefits, Types, & ... - Inventory management is the process of tracking and controlling goods flow through stages like demand planning, ordering, delivery, tracking, sale, reviewing, and replenishment to optimize stock levels and supply chain efficiency.

Inventory Management: How it Works and Tools (2025) - Effective inventory management uses techniques such as Economic Order Quantity, demand planning, inventory audits, and advanced technologies like RFID and barcodes to balance stock and improve cash flow.

Inventory Management Guide + Methods & Examples - Inventory management methods include spreadsheets, automated systems, ERP software, and multichannel management to track and control inventory across sourcing, storage, and sales stages.

dowidth.com

dowidth.com