Milk run logistics optimizes transportation by consolidating multiple pickups or deliveries into a single route, reducing costs and minimizing inventory levels. Just-in-time delivery focuses on synchronizing supply arrivals precisely when needed to eliminate storage expenses and enhance production efficiency. Explore more to understand how these strategies can transform your supply chain operations.

Why it is important

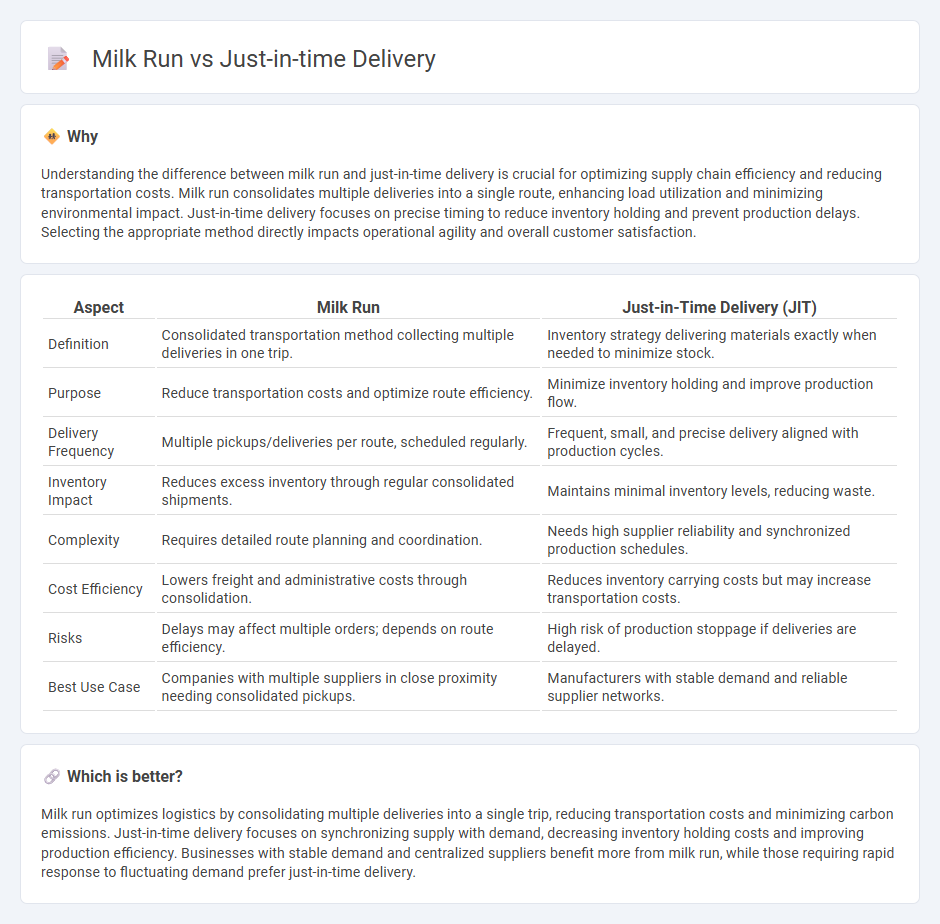

Understanding the difference between milk run and just-in-time delivery is crucial for optimizing supply chain efficiency and reducing transportation costs. Milk run consolidates multiple deliveries into a single route, enhancing load utilization and minimizing environmental impact. Just-in-time delivery focuses on precise timing to reduce inventory holding and prevent production delays. Selecting the appropriate method directly impacts operational agility and overall customer satisfaction.

Comparison Table

| Aspect | Milk Run | Just-in-Time Delivery (JIT) |

|---|---|---|

| Definition | Consolidated transportation method collecting multiple deliveries in one trip. | Inventory strategy delivering materials exactly when needed to minimize stock. |

| Purpose | Reduce transportation costs and optimize route efficiency. | Minimize inventory holding and improve production flow. |

| Delivery Frequency | Multiple pickups/deliveries per route, scheduled regularly. | Frequent, small, and precise delivery aligned with production cycles. |

| Inventory Impact | Reduces excess inventory through regular consolidated shipments. | Maintains minimal inventory levels, reducing waste. |

| Complexity | Requires detailed route planning and coordination. | Needs high supplier reliability and synchronized production schedules. |

| Cost Efficiency | Lowers freight and administrative costs through consolidation. | Reduces inventory carrying costs but may increase transportation costs. |

| Risks | Delays may affect multiple orders; depends on route efficiency. | High risk of production stoppage if deliveries are delayed. |

| Best Use Case | Companies with multiple suppliers in close proximity needing consolidated pickups. | Manufacturers with stable demand and reliable supplier networks. |

Which is better?

Milk run optimizes logistics by consolidating multiple deliveries into a single trip, reducing transportation costs and minimizing carbon emissions. Just-in-time delivery focuses on synchronizing supply with demand, decreasing inventory holding costs and improving production efficiency. Businesses with stable demand and centralized suppliers benefit more from milk run, while those requiring rapid response to fluctuating demand prefer just-in-time delivery.

Connection

Milk run and just-in-time (JIT) delivery are closely connected through their shared goal of reducing inventory costs and improving supply chain efficiency. Milk run consolidates multiple deliveries into a single route, ensuring frequent and reliable supply to production lines that operate on JIT principles. This synchronization minimizes waste, lowers transportation expenses, and supports lean manufacturing by delivering materials precisely when needed.

Key Terms

Inventory Management

Just-in-time delivery minimizes inventory holding costs by synchronizing shipments with production schedules, ensuring materials arrive exactly when needed to reduce storage and obsolescence. Milk run logistics optimizes inventory replenishment by consolidating multiple deliveries into a single route, enhancing supply chain efficiency and reducing transportation costs. Explore how these inventory management strategies can streamline your operations and improve supply chain responsiveness.

Route Optimization

Just-in-time delivery streamlines inventory management by scheduling precise shipments to minimize stockholding, while milk run optimizes transportation by consolidating multiple deliveries into a single route to reduce costs and emissions. Route optimization algorithms enhance both methods by analyzing traffic patterns, delivery windows, and vehicle capacity to determine the most efficient paths. Discover how advanced routing software revolutionizes supply chain logistics for improved timeliness and sustainability.

Lead Time

Just-in-time delivery minimizes lead time by synchronizing inventory arrival precisely with production schedules, reducing storage costs and enhancing efficiency. Milk run consolidates deliveries from multiple suppliers into a single route, potentially increasing lead time but optimizing transportation expenses. Explore how these logistics strategies impact your supply chain's lead time and overall performance.

Source and External Links

Just in Time Delivery: What is it, and How Does it Affect ... - Just in time delivery is the process of completing production so that minimal inventory satisfies demand and delivery occurs exactly when customers want it, with examples like restaurants and grocery delivery highlighting its importance for freshness and timing.

Just In Time (JIT) Delivery: The Ultimate Guide - JIT delivery is a supply chain approach focusing on producing and delivering products on demand to increase efficiency, reduce inventory costs, and respond quickly to customer needs without maintaining excess stock.

What is JIT Delivery? - Just-In-Time delivery is a logistics strategy minimizing inventory storage costs by ensuring goods arrive exactly when needed, leveraging lean manufacturing and "pull" production to eliminate waste and optimize resources.

dowidth.com

dowidth.com