Milk run delivery optimizes logistics by consolidating shipments from multiple suppliers into a single route, reducing transportation costs and enhancing inventory control. Centralized distribution involves storing products at a central hub to streamline order fulfillment and improve demand forecasting accuracy. Discover how these strategies can transform your supply chain efficiency.

Why it is important

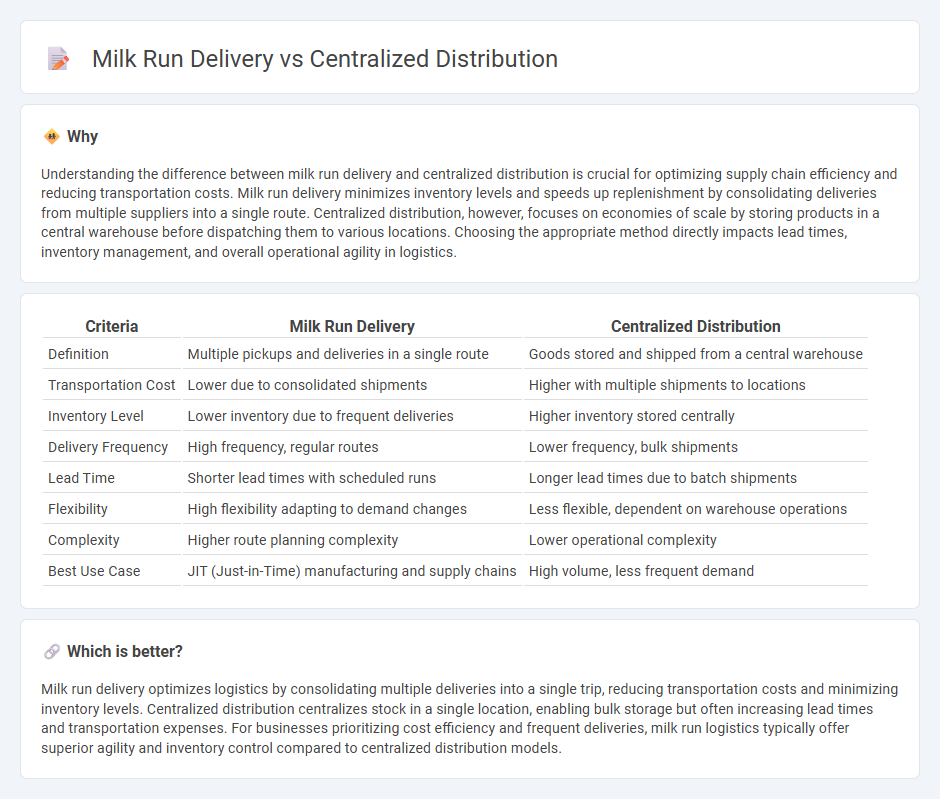

Understanding the difference between milk run delivery and centralized distribution is crucial for optimizing supply chain efficiency and reducing transportation costs. Milk run delivery minimizes inventory levels and speeds up replenishment by consolidating deliveries from multiple suppliers into a single route. Centralized distribution, however, focuses on economies of scale by storing products in a central warehouse before dispatching them to various locations. Choosing the appropriate method directly impacts lead times, inventory management, and overall operational agility in logistics.

Comparison Table

| Criteria | Milk Run Delivery | Centralized Distribution |

|---|---|---|

| Definition | Multiple pickups and deliveries in a single route | Goods stored and shipped from a central warehouse |

| Transportation Cost | Lower due to consolidated shipments | Higher with multiple shipments to locations |

| Inventory Level | Lower inventory due to frequent deliveries | Higher inventory stored centrally |

| Delivery Frequency | High frequency, regular routes | Lower frequency, bulk shipments |

| Lead Time | Shorter lead times with scheduled runs | Longer lead times due to batch shipments |

| Flexibility | High flexibility adapting to demand changes | Less flexible, dependent on warehouse operations |

| Complexity | Higher route planning complexity | Lower operational complexity |

| Best Use Case | JIT (Just-in-Time) manufacturing and supply chains | High volume, less frequent demand |

Which is better?

Milk run delivery optimizes logistics by consolidating multiple deliveries into a single trip, reducing transportation costs and minimizing inventory levels. Centralized distribution centralizes stock in a single location, enabling bulk storage but often increasing lead times and transportation expenses. For businesses prioritizing cost efficiency and frequent deliveries, milk run logistics typically offer superior agility and inventory control compared to centralized distribution models.

Connection

Milk run delivery optimizes logistics by enabling frequent, scheduled pickups and deliveries from multiple suppliers, reducing transportation costs and inventory levels. Centralized distribution consolidates goods at a single hub, streamlining order fulfillment and enhancing supply chain visibility. Together, these methods improve efficiency by synchronizing supply flows and minimizing lead times across the logistics network.

Key Terms

Distribution Center (Centralized Distribution)

Centralized distribution relies on a single Distribution Center (DC) to consolidate inventory and fulfill customer orders, optimizing warehouse management and reducing overall storage costs. Milk run delivery, in contrast, involves multiple stops with smaller loads, enhancing route efficiency and minimizing transportation expenses but requiring complex coordination. Explore the advantages of centralized distribution to improve supply chain efficiency and reduce operational costs.

Route Optimization (Milk Run Delivery)

Route optimization in milk run delivery significantly reduces transportation costs by consolidating shipments from multiple suppliers into a single, efficient route, minimizing fuel consumption and vehicle mileage. Unlike centralized distribution, which relies on a single hub and frequent long-haul trips, milk run delivery uses continuous routing strategies to ensure timely, just-in-time inventory replenishment and lower lead times. Explore how route optimization in milk run delivery enhances supply chain efficiency and sustainability by reducing waste and improving asset utilization.

Inventory Consolidation

Centralized distribution streamlines inventory consolidation by aggregating stock at a single hub, reducing safety stock and improving demand forecasting accuracy. Milk run delivery optimizes inventory flow through scheduled multiple pickups and drop-offs, minimizing excess inventory and enhancing supply chain responsiveness. Explore how each method impacts inventory consolidation strategies to optimize your supply chain efficiency.

Source and External Links

Regional vs. Centralized Distribution: Mastering the Supply Chain - Centralized distribution involves a single hub performing all logistics operations such as inventory consolidation and dispatching, offering benefits like lower storage costs and efficient warehouse management but may lead to longer transport times and higher outbound shipping costs for distant locations.

What Are the Pros and Cons of Centralized and Decentralized Distribution? - Centralized distribution is a traditional model where a central hub manages nearly all logistics functions, providing advantages in cost efficiency and technology implementation while facing challenges like potential vulnerability to disruptions and longer delivery distances.

Regional vs. Centralized Distribution: Evaluating Approaches for Logistics - Centralized distribution consolidates inventory and distribution activities within one hub, enabling economies of scale, reduced per-unit handling costs, and streamlined logistics, especially beneficial for shippers operating over large geographical areas.

dowidth.com

dowidth.com