Collaborative logistics involves multiple companies working together to optimize supply chain processes, leveraging shared resources and information to reduce costs and improve efficiency. Shared logistics focuses on resource pooling, such as using common warehousing or transportation assets, to minimize waste and maximize asset utilization. Explore how collaborative and shared logistics strategies can transform supply chain performance in your business.

Why it is important

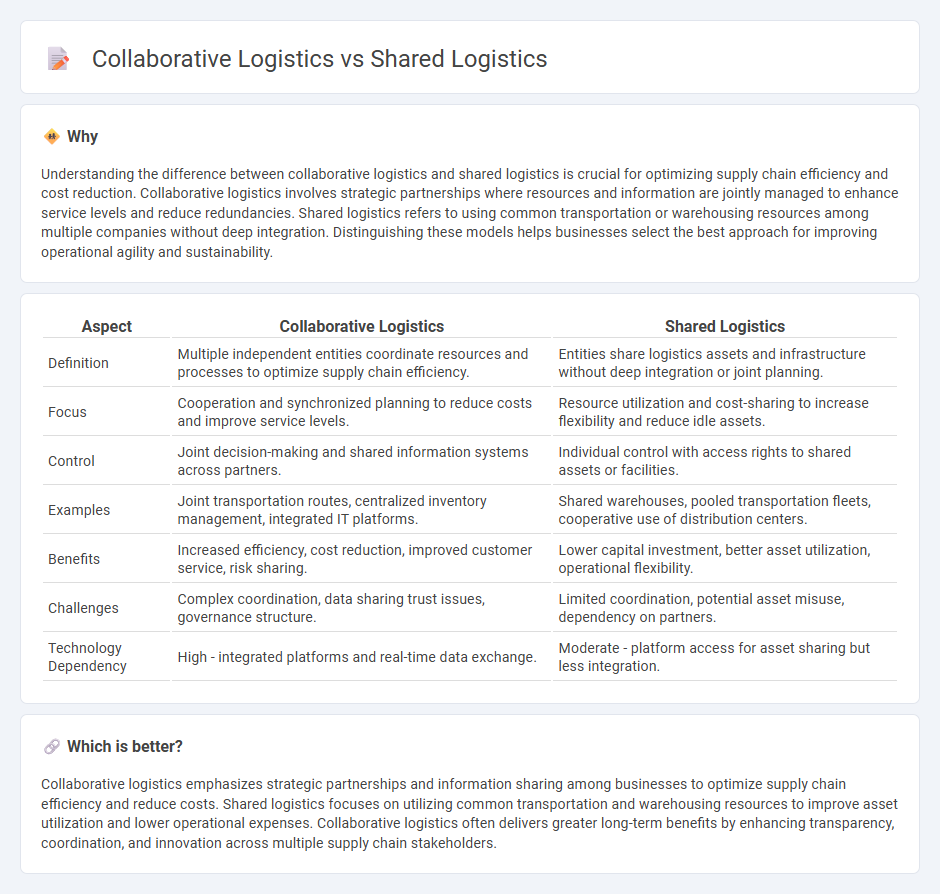

Understanding the difference between collaborative logistics and shared logistics is crucial for optimizing supply chain efficiency and cost reduction. Collaborative logistics involves strategic partnerships where resources and information are jointly managed to enhance service levels and reduce redundancies. Shared logistics refers to using common transportation or warehousing resources among multiple companies without deep integration. Distinguishing these models helps businesses select the best approach for improving operational agility and sustainability.

Comparison Table

| Aspect | Collaborative Logistics | Shared Logistics |

|---|---|---|

| Definition | Multiple independent entities coordinate resources and processes to optimize supply chain efficiency. | Entities share logistics assets and infrastructure without deep integration or joint planning. |

| Focus | Cooperation and synchronized planning to reduce costs and improve service levels. | Resource utilization and cost-sharing to increase flexibility and reduce idle assets. |

| Control | Joint decision-making and shared information systems across partners. | Individual control with access rights to shared assets or facilities. |

| Examples | Joint transportation routes, centralized inventory management, integrated IT platforms. | Shared warehouses, pooled transportation fleets, cooperative use of distribution centers. |

| Benefits | Increased efficiency, cost reduction, improved customer service, risk sharing. | Lower capital investment, better asset utilization, operational flexibility. |

| Challenges | Complex coordination, data sharing trust issues, governance structure. | Limited coordination, potential asset misuse, dependency on partners. |

| Technology Dependency | High - integrated platforms and real-time data exchange. | Moderate - platform access for asset sharing but less integration. |

Which is better?

Collaborative logistics emphasizes strategic partnerships and information sharing among businesses to optimize supply chain efficiency and reduce costs. Shared logistics focuses on utilizing common transportation and warehousing resources to improve asset utilization and lower operational expenses. Collaborative logistics often delivers greater long-term benefits by enhancing transparency, coordination, and innovation across multiple supply chain stakeholders.

Connection

Collaborative logistics and shared logistics both focus on maximizing efficiency and reducing costs through cooperation among multiple parties in the supply chain. Collaborative logistics involves coordinated planning and execution between companies to optimize transportation and inventory, while shared logistics emphasizes the utilization of common logistics resources such as warehouses and vehicles. Both approaches drive sustainability and operational effectiveness by leveraging combined assets and data sharing.

Key Terms

**Shared Logistics:**

Shared logistics leverages the pooling of transportation resources among multiple businesses to reduce costs and increase efficiency by maximizing truckload utilization. This approach often involves shared warehouses, vehicles, and distribution channels that enhance supply chain transparency and reduce environmental impact through lower emissions per shipment. Discover how shared logistics can transform your supply chain management and drive operational savings.

Resource Pooling

Shared logistics involves different companies sharing transportation and warehousing resources independently, optimizing asset utilization without deep integration. Collaborative logistics centers on seamless cooperation through combined planning and execution, enabling resource pooling that reduces costs and enhances supply chain efficiency. Explore how resource pooling in collaborative logistics transforms industry practices for greater competitiveness.

Cost Sharing

Shared logistics reduces transportation and warehousing expenses by pooling resources between companies, leading to significant cost savings through joint use of assets. Collaborative logistics involves deeper integration and coordination of supply chain activities, optimizing routes, inventory, and demand forecasting to minimize overall operational costs. Explore the benefits of cost sharing in logistics to enhance efficiency and profitability.

Source and External Links

Shared Logistics vs Freight Routes - UNIS - Shared Logistics is a collaborative approach where multiple businesses share resources and infrastructure to streamline operations, improving cost-sharing and sustainability, while Freight Routes focus on optimizing the physical pathways for moving goods efficiently across various transport modes.

The Pros and Cons of a Shared Logistics Network - A shared logistics network allows businesses to outsource shared assets instead of dedicated capacity, offering enhanced flexibility, risk reduction, cost savings, and sustainability, often integrated with digital platforms to connect supply and demand efficiently.

Share Logistics - Expect more for your global cargo. - Share Logistics provides personalized global shipping solutions across multiple transport modes, specializing in customized logistics services with local expertise worldwide, serving industries with complex cargo needs through a mid-sized, client-focused approach.

dowidth.com

dowidth.com