Dynamic rerouting optimizes transportation routes in real-time based on traffic, weather, and delivery priorities to reduce delays and improve efficiency. Capacity planning involves forecasting demand and allocating resources such as labor, vehicles, and storage to ensure supply chain stability and cost-effectiveness. Explore how integrating dynamic rerouting with capacity planning enhances logistics performance and customer satisfaction.

Why it is important

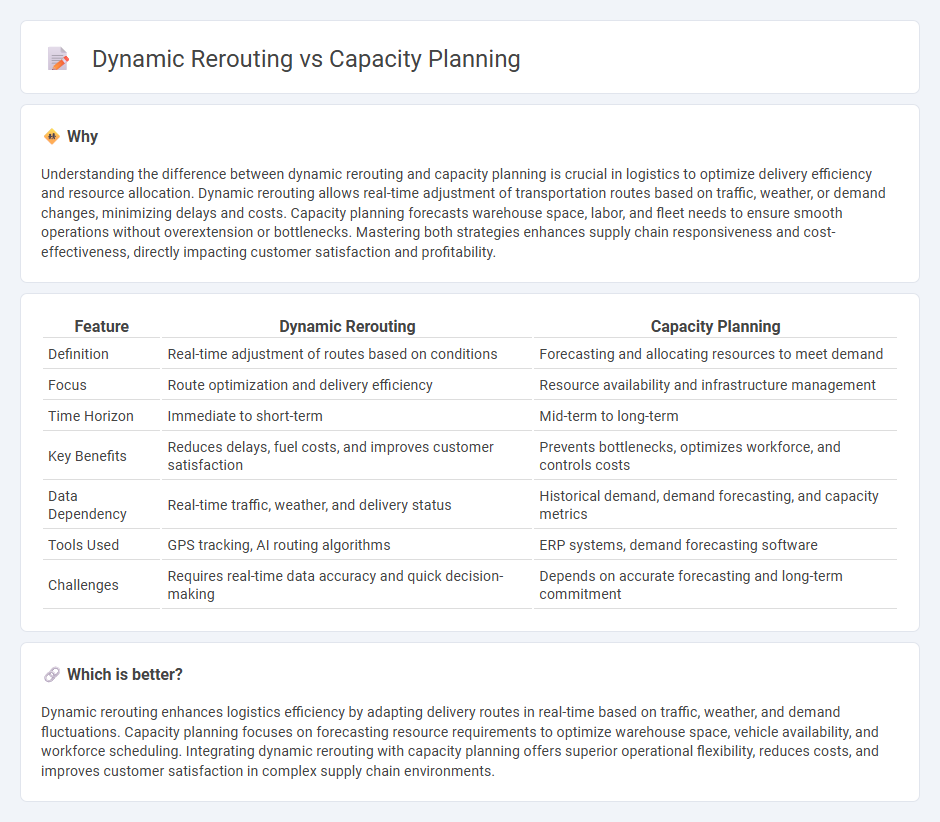

Understanding the difference between dynamic rerouting and capacity planning is crucial in logistics to optimize delivery efficiency and resource allocation. Dynamic rerouting allows real-time adjustment of transportation routes based on traffic, weather, or demand changes, minimizing delays and costs. Capacity planning forecasts warehouse space, labor, and fleet needs to ensure smooth operations without overextension or bottlenecks. Mastering both strategies enhances supply chain responsiveness and cost-effectiveness, directly impacting customer satisfaction and profitability.

Comparison Table

| Feature | Dynamic Rerouting | Capacity Planning |

|---|---|---|

| Definition | Real-time adjustment of routes based on conditions | Forecasting and allocating resources to meet demand |

| Focus | Route optimization and delivery efficiency | Resource availability and infrastructure management |

| Time Horizon | Immediate to short-term | Mid-term to long-term |

| Key Benefits | Reduces delays, fuel costs, and improves customer satisfaction | Prevents bottlenecks, optimizes workforce, and controls costs |

| Data Dependency | Real-time traffic, weather, and delivery status | Historical demand, demand forecasting, and capacity metrics |

| Tools Used | GPS tracking, AI routing algorithms | ERP systems, demand forecasting software |

| Challenges | Requires real-time data accuracy and quick decision-making | Depends on accurate forecasting and long-term commitment |

Which is better?

Dynamic rerouting enhances logistics efficiency by adapting delivery routes in real-time based on traffic, weather, and demand fluctuations. Capacity planning focuses on forecasting resource requirements to optimize warehouse space, vehicle availability, and workforce scheduling. Integrating dynamic rerouting with capacity planning offers superior operational flexibility, reduces costs, and improves customer satisfaction in complex supply chain environments.

Connection

Dynamic rerouting enhances logistics efficiency by constantly adjusting routes based on real-time data such as traffic conditions, weather, and delivery urgency, which directly influences capacity planning decisions. Effective capacity planning relies on this adaptive routing information to allocate resources, optimize fleet utilization, and prevent bottlenecks. Integrating these processes ensures streamlined operations, reduced transportation costs, and improved customer satisfaction in supply chain management.

Key Terms

**Capacity Planning:**

Capacity planning involves forecasting network demand and allocating resources to ensure sufficient bandwidth and avoid congestion, minimizing downtime and delays. It uses historical data, traffic patterns, and performance metrics to optimize infrastructure and support service quality. Explore deeper insights into how capacity planning enhances network efficiency and scalability.

Demand Forecasting

Capacity planning integrates demand forecasting to allocate resources efficiently, ensuring network and operational capabilities meet projected needs. Dynamic rerouting relies on real-time data to adjust pathways instantly, minimizing congestion and optimizing flow based on current demand. Explore more to understand how these strategies complement demand forecasting for enhanced operational efficiency.

Resource Allocation

Capacity planning ensures optimal resource allocation by forecasting demand and provisioning adequate network bandwidth and infrastructure, minimizing congestion and service disruptions. Dynamic rerouting reallocates resources in real-time by adjusting traffic paths to avoid network failures or bottlenecks, enhancing resilience and load balancing. Explore deeper insights into optimizing resource allocation through capacity planning and dynamic rerouting strategies.

Source and External Links

What Is Capacity Planning? - Capacity planning is a strategic process to analyze and align an organization's production capacity and resources to meet current and future demand efficiently, balancing resource utilization and market responsiveness through forecasting and agile adjustments.

What Is Capacity Planning and Should You Use It? [2025] - Capacity planning proactively assesses and prepares resources such as workforce, time, and budget to meet current and future project demands, using strategies like lead, lag, and match planning to optimize resource alignment and avoid bottlenecks.

Capacity planning - Wikipedia - Capacity planning determines the production capacity or IT resources an organization needs to meet changing demand, aiming to minimize inefficiencies from under- or over-utilization by calculating capacity based on workers, shifts, utilization, and efficiency.

dowidth.com

dowidth.com