Cold chain visibility involves real-time monitoring and tracking of temperature-sensitive goods to ensure compliance with safety standards during transportation and storage. Cold chain optimization focuses on enhancing operational efficiency by minimizing spoilage, reducing costs, and improving delivery speed through advanced technologies and data analytics. Explore innovative solutions that integrate visibility and optimization to transform cold chain management.

Why it is important

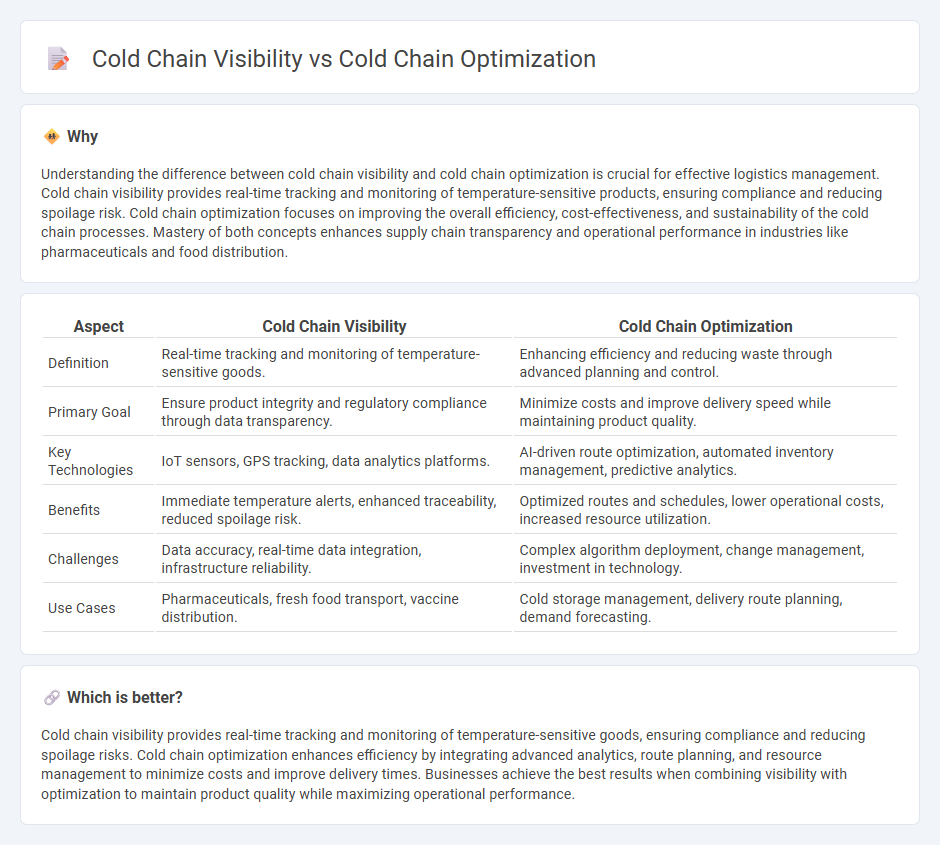

Understanding the difference between cold chain visibility and cold chain optimization is crucial for effective logistics management. Cold chain visibility provides real-time tracking and monitoring of temperature-sensitive products, ensuring compliance and reducing spoilage risk. Cold chain optimization focuses on improving the overall efficiency, cost-effectiveness, and sustainability of the cold chain processes. Mastery of both concepts enhances supply chain transparency and operational performance in industries like pharmaceuticals and food distribution.

Comparison Table

| Aspect | Cold Chain Visibility | Cold Chain Optimization |

|---|---|---|

| Definition | Real-time tracking and monitoring of temperature-sensitive goods. | Enhancing efficiency and reducing waste through advanced planning and control. |

| Primary Goal | Ensure product integrity and regulatory compliance through data transparency. | Minimize costs and improve delivery speed while maintaining product quality. |

| Key Technologies | IoT sensors, GPS tracking, data analytics platforms. | AI-driven route optimization, automated inventory management, predictive analytics. |

| Benefits | Immediate temperature alerts, enhanced traceability, reduced spoilage risk. | Optimized routes and schedules, lower operational costs, increased resource utilization. |

| Challenges | Data accuracy, real-time data integration, infrastructure reliability. | Complex algorithm deployment, change management, investment in technology. |

| Use Cases | Pharmaceuticals, fresh food transport, vaccine distribution. | Cold storage management, delivery route planning, demand forecasting. |

Which is better?

Cold chain visibility provides real-time tracking and monitoring of temperature-sensitive goods, ensuring compliance and reducing spoilage risks. Cold chain optimization enhances efficiency by integrating advanced analytics, route planning, and resource management to minimize costs and improve delivery times. Businesses achieve the best results when combining visibility with optimization to maintain product quality while maximizing operational performance.

Connection

Cold chain visibility provides real-time tracking and monitoring of temperature-sensitive goods, enabling precise data collection during transportation and storage. Cold chain optimization leverages this data to improve operational efficiency, reduce spoilage, and ensure regulatory compliance throughout the supply chain. Enhanced visibility directly supports optimization efforts by identifying inefficiencies and enabling proactive interventions to maintain product integrity.

Key Terms

**Cold Chain Optimization:**

Cold Chain Optimization enhances temperature-controlled logistics by improving inventory management, reducing spoilage, and minimizing transportation costs through data-driven insights. It leverages predictive analytics and real-time monitoring to streamline routes, optimize storage conditions, and ensure product integrity from origin to destination. Discover how advanced optimization techniques can transform your cold chain efficiency and ensure compliance with stringent regulatory standards.

Route Planning

Cold chain optimization involves streamlining route planning to minimize transit time and temperature deviations, ensuring product integrity from warehouse to delivery. Cold chain visibility leverages real-time tracking technologies to monitor shipments' exact locations and conditions, enabling proactive adjustments during transit. Explore deeper insights into how enhanced route planning combined with advanced visibility tools can revolutionize cold chain management.

Inventory Management

Cold chain optimization enhances inventory management by improving temperature control, reducing spoilage, and ensuring timely delivery of perishable goods. Cold chain visibility provides real-time tracking and monitoring of inventory conditions, enabling proactive decision-making and minimizing stock losses. Explore how integrating both strategies can revolutionize your inventory management in the cold chain.

Source and External Links

Streamlining Cold Chain Operations: 10 Best Practices - Cold chain optimization involves implementing robust temperature monitoring systems, designing resilient networks, and proactively managing risks through technology and contingency planning to maintain product integrity.

Cold supply chain: reducing costs and enhancing efficiency - Effective cold chain optimization includes strategic warehouse placement, network optimization, simulation, and risk management to reduce costs and enhance service levels while maintaining temperature-controlled conditions.

What is Cold Chain Management & Logistics? - Optimization is supported by real-time temperature monitoring, data-driven decision making, and standardizing processes to improve operational efficiency and ensure compliance throughout the temperature-sensitive supply chain.

dowidth.com

dowidth.com