Collaborative logistics integrates multiple stakeholders and resources to streamline supply chain operations, enhancing efficiency and reducing costs through shared information and coordinated planning. Flexible logistics adapts quickly to changing market demands and disruptions by employing scalable solutions and agile processes, ensuring responsiveness and resilience in delivery performance. Discover more about how these strategic approaches transform supply chain management.

Why it is important

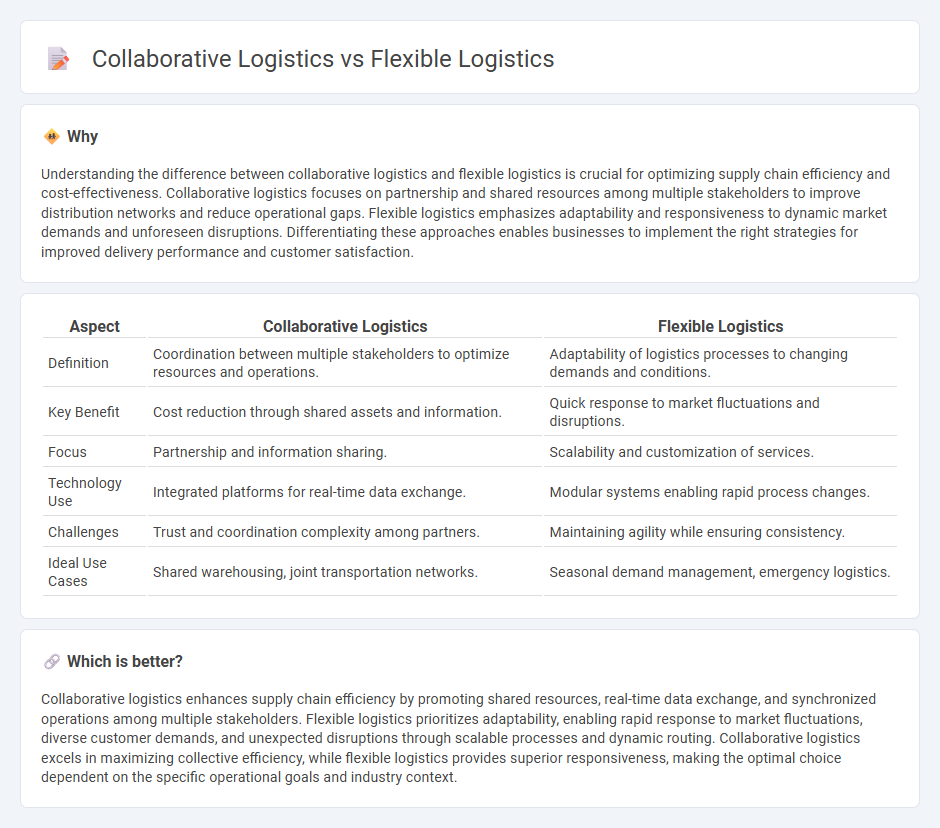

Understanding the difference between collaborative logistics and flexible logistics is crucial for optimizing supply chain efficiency and cost-effectiveness. Collaborative logistics focuses on partnership and shared resources among multiple stakeholders to improve distribution networks and reduce operational gaps. Flexible logistics emphasizes adaptability and responsiveness to dynamic market demands and unforeseen disruptions. Differentiating these approaches enables businesses to implement the right strategies for improved delivery performance and customer satisfaction.

Comparison Table

| Aspect | Collaborative Logistics | Flexible Logistics |

|---|---|---|

| Definition | Coordination between multiple stakeholders to optimize resources and operations. | Adaptability of logistics processes to changing demands and conditions. |

| Key Benefit | Cost reduction through shared assets and information. | Quick response to market fluctuations and disruptions. |

| Focus | Partnership and information sharing. | Scalability and customization of services. |

| Technology Use | Integrated platforms for real-time data exchange. | Modular systems enabling rapid process changes. |

| Challenges | Trust and coordination complexity among partners. | Maintaining agility while ensuring consistency. |

| Ideal Use Cases | Shared warehousing, joint transportation networks. | Seasonal demand management, emergency logistics. |

Which is better?

Collaborative logistics enhances supply chain efficiency by promoting shared resources, real-time data exchange, and synchronized operations among multiple stakeholders. Flexible logistics prioritizes adaptability, enabling rapid response to market fluctuations, diverse customer demands, and unexpected disruptions through scalable processes and dynamic routing. Collaborative logistics excels in maximizing collective efficiency, while flexible logistics provides superior responsiveness, making the optimal choice dependent on the specific operational goals and industry context.

Connection

Collaborative logistics leverages shared resources and real-time data exchange among multiple stakeholders to enhance supply chain efficiency and reduce costs. Flexible logistics adapts quickly to changing demands and disruptions by utilizing agile transportation and warehousing strategies. The connection lies in their mutual reliance on dynamic coordination and information sharing to optimize operations and improve responsiveness across supply networks.

Key Terms

**Flexible Logistics:**

Flexible logistics emphasizes adaptive supply chain management through scalable operations, real-time data integration, and dynamic routing to meet fluctuating demands efficiently. It optimizes resource utilization by leveraging advanced technologies like AI and IoT to respond swiftly to market changes and unexpected disruptions. Explore how flexible logistics can transform your supply chain and enhance operational resilience.

Agility

Flexible logistics emphasizes rapid adjustment of supply chain operations to accommodate changing demands and unforeseen disruptions, leveraging modular processes and real-time data analytics. Collaborative logistics involves multiple stakeholders sharing resources and information to enhance overall supply chain efficiency and transparency, fostering coordinated decision-making. Explore how integrating agility through flexible and collaborative logistics can transform supply chain resilience and responsiveness.

Scalability

Flexible logistics emphasizes adaptable supply chain solutions that scale in response to fluctuating demand and market conditions, leveraging technology for real-time adjustments. Collaborative logistics integrates multiple stakeholders, such as suppliers and transport providers, optimizing resources and capacity to enhance scalability through shared information and coordinated efforts. Explore how scalability in both approaches can transform your logistics strategy for sustainable growth.

Source and External Links

7 Ways Flexible Logistics Improves Supply Chains - Easy4Pro - Flexible logistics is a strategic approach that enables businesses to adapt swiftly to market changes, disruptions, and customer demands, enhancing supply chain efficiency, cost optimization, and customer satisfaction through real-time decision-making and operational flexibility.

Flexible Logistics: What It Means and Why It's Important? - corporate.nvisionglobal.com - Flexible logistics prioritizes adaptability and responsiveness over rigid planning, offering features like real-time shipment tracking, customizable last-mile delivery, and scalable solutions to help businesses proactively manage unpredictable market conditions.

Keys to flexible logistics - Mecalux.com - Flexible logistics involves adapting warehouse operations and distribution processes to handle unforeseen events and market fluctuations without disrupting performance, often utilizing digital tools like warehouse management systems (WMS) to optimize resources and maintain supply chain continuity.

dowidth.com

dowidth.com