Shared warehousing offers flexible storage solutions by allowing multiple businesses to share space and costs, optimizing inventory management without large capital investment. Fulfillment centers specialize in processing orders quickly, including picking, packing, and shipping, enabling faster delivery and improved customer satisfaction. Explore the key differences and benefits to determine which logistics solution best fits your supply chain needs.

Why it is important

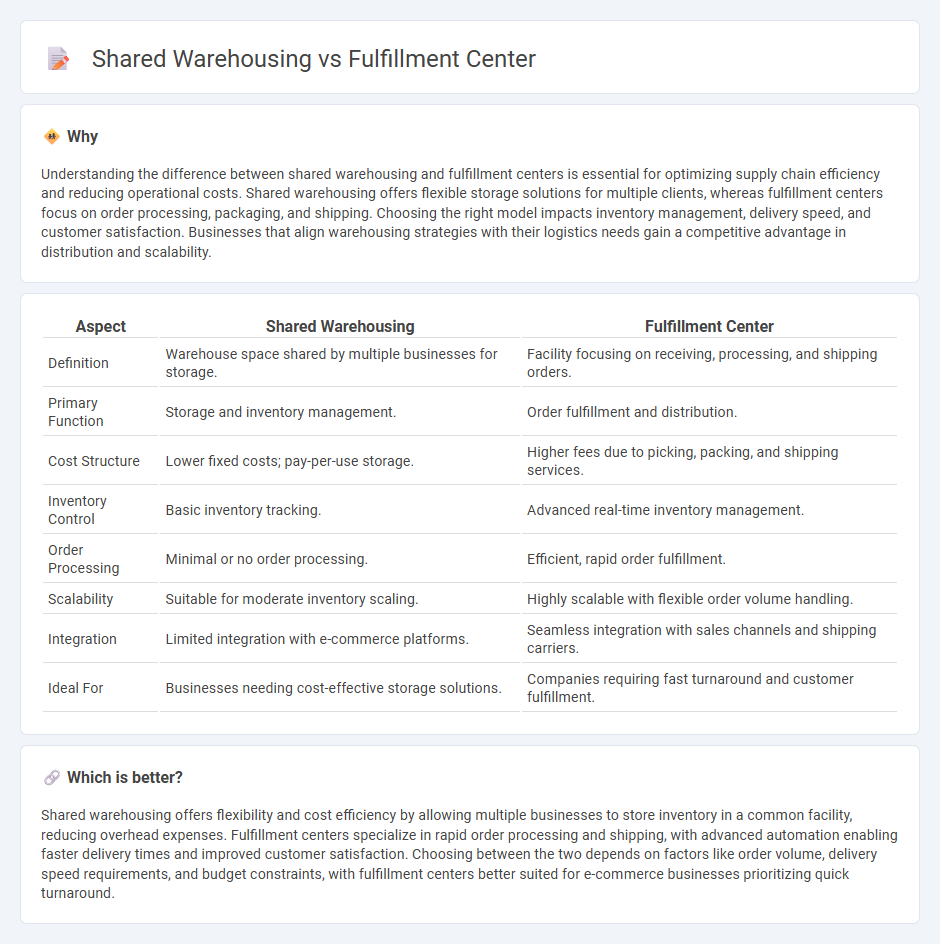

Understanding the difference between shared warehousing and fulfillment centers is essential for optimizing supply chain efficiency and reducing operational costs. Shared warehousing offers flexible storage solutions for multiple clients, whereas fulfillment centers focus on order processing, packaging, and shipping. Choosing the right model impacts inventory management, delivery speed, and customer satisfaction. Businesses that align warehousing strategies with their logistics needs gain a competitive advantage in distribution and scalability.

Comparison Table

| Aspect | Shared Warehousing | Fulfillment Center |

|---|---|---|

| Definition | Warehouse space shared by multiple businesses for storage. | Facility focusing on receiving, processing, and shipping orders. |

| Primary Function | Storage and inventory management. | Order fulfillment and distribution. |

| Cost Structure | Lower fixed costs; pay-per-use storage. | Higher fees due to picking, packing, and shipping services. |

| Inventory Control | Basic inventory tracking. | Advanced real-time inventory management. |

| Order Processing | Minimal or no order processing. | Efficient, rapid order fulfillment. |

| Scalability | Suitable for moderate inventory scaling. | Highly scalable with flexible order volume handling. |

| Integration | Limited integration with e-commerce platforms. | Seamless integration with sales channels and shipping carriers. |

| Ideal For | Businesses needing cost-effective storage solutions. | Companies requiring fast turnaround and customer fulfillment. |

Which is better?

Shared warehousing offers flexibility and cost efficiency by allowing multiple businesses to store inventory in a common facility, reducing overhead expenses. Fulfillment centers specialize in rapid order processing and shipping, with advanced automation enabling faster delivery times and improved customer satisfaction. Choosing between the two depends on factors like order volume, delivery speed requirements, and budget constraints, with fulfillment centers better suited for e-commerce businesses prioritizing quick turnaround.

Connection

Shared warehousing and fulfillment centers are interconnected through the efficient allocation of storage space and streamlined order processing to reduce costs and improve delivery speed. By leveraging shared warehousing, fulfillment centers can scale operations flexibly, accommodating varying inventory levels without long-term commitments. This integration enhances supply chain agility, minimizes lead times, and optimizes resource utilization across logistics networks.

Key Terms

Inventory Management

Fulfillment centers specialize in streamlined inventory management by handling order processing, storage, and shipping under one roof, ensuring faster turnaround times and accurate stock levels. Shared warehousing offers flexible space and cost-saving benefits but often requires integration of separate inventory systems, which can lead to complexities in real-time stock tracking. Explore how these differences impact your supply chain efficiency and inventory accuracy to choose the best option for your business.

Order Processing

Fulfillment centers specialize in rapid and accurate order processing by using advanced automation and real-time inventory tracking to ensure timely shipment and customer satisfaction. Shared warehousing offers cost-effective storage solutions but often lacks the streamlined order processing capabilities found in dedicated fulfillment centers. Explore detailed comparisons to determine which option best suits your business's order fulfillment needs.

Space Utilization

Fulfillment centers optimize space utilization through advanced automation, real-time inventory tracking, and strategic layout designs that maximize storage density and picking efficiency. Shared warehousing typically involves multiple clients sharing the same physical space, which can lead to less efficient space use due to varied product types and handling requirements. Explore the key differences in space optimization strategies to determine which solution best supports your supply chain needs.

Source and External Links

Fulfillment Center & Warehousing Services: Tips and Tactics - A fulfillment center is a facility where a company or third-party logistics provider manages inventory, picks, packs, and ships orders directly to customers or retailers, acting as the hub for the entire order fulfillment process in ecommerce and B2B operations.

What Is a Fulfillment Center? Everything You Need to Know - Fulfillment centers are third-party providers that store inventory and efficiently process and ship products to customers using technology such as warehouse management systems to ensure fast and accurate order fulfillment.

Fulfillment Center vs. Warehouse: What's Best for You? - Fulfillment centers specialize in managing B2C order fulfillment by handling inventory, picking, packing, shipping, and real-time inventory management, enabling brands to focus on sales and growth while ensuring timely customer delivery.

dowidth.com

dowidth.com