Cold chain visibility provides real-time tracking and transparency of temperature-sensitive shipments throughout the supply chain, ensuring compliance with regulatory standards and minimizing product spoilage. Cold chain monitoring focuses on continuous data collection from sensors to detect temperature fluctuations and environmental conditions, enabling proactive interventions to maintain product integrity. Explore detailed insights to understand how these technologies transform perishables logistics and improve supply chain resilience.

Why it is important

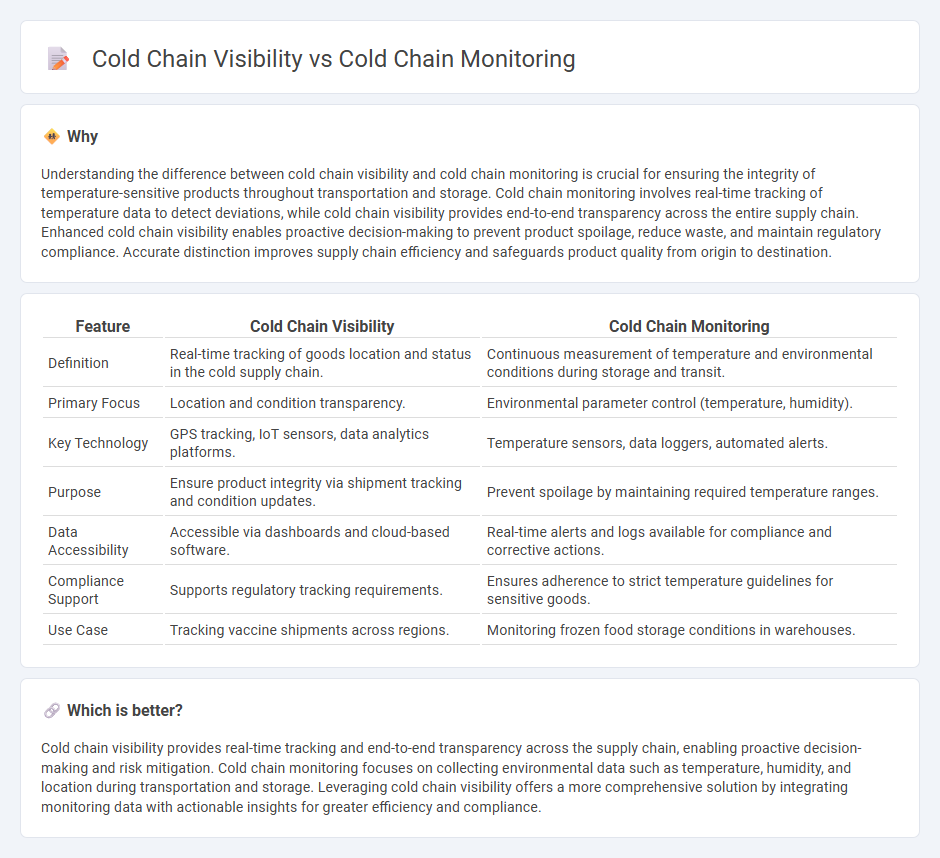

Understanding the difference between cold chain visibility and cold chain monitoring is crucial for ensuring the integrity of temperature-sensitive products throughout transportation and storage. Cold chain monitoring involves real-time tracking of temperature data to detect deviations, while cold chain visibility provides end-to-end transparency across the entire supply chain. Enhanced cold chain visibility enables proactive decision-making to prevent product spoilage, reduce waste, and maintain regulatory compliance. Accurate distinction improves supply chain efficiency and safeguards product quality from origin to destination.

Comparison Table

| Feature | Cold Chain Visibility | Cold Chain Monitoring |

|---|---|---|

| Definition | Real-time tracking of goods location and status in the cold supply chain. | Continuous measurement of temperature and environmental conditions during storage and transit. |

| Primary Focus | Location and condition transparency. | Environmental parameter control (temperature, humidity). |

| Key Technology | GPS tracking, IoT sensors, data analytics platforms. | Temperature sensors, data loggers, automated alerts. |

| Purpose | Ensure product integrity via shipment tracking and condition updates. | Prevent spoilage by maintaining required temperature ranges. |

| Data Accessibility | Accessible via dashboards and cloud-based software. | Real-time alerts and logs available for compliance and corrective actions. |

| Compliance Support | Supports regulatory tracking requirements. | Ensures adherence to strict temperature guidelines for sensitive goods. |

| Use Case | Tracking vaccine shipments across regions. | Monitoring frozen food storage conditions in warehouses. |

Which is better?

Cold chain visibility provides real-time tracking and end-to-end transparency across the supply chain, enabling proactive decision-making and risk mitigation. Cold chain monitoring focuses on collecting environmental data such as temperature, humidity, and location during transportation and storage. Leveraging cold chain visibility offers a more comprehensive solution by integrating monitoring data with actionable insights for greater efficiency and compliance.

Connection

Cold chain visibility relies on real-time cold chain monitoring technologies that track temperature, humidity, and location of perishable goods throughout the supply chain. Sensors and IoT devices provide continuous data, enabling stakeholders to quickly identify and address deviations that could compromise product quality. This integration ensures regulatory compliance, reduces spoilage, and optimizes inventory management in logistics operations.

Key Terms

**Cold Chain Monitoring:**

Cold chain monitoring involves real-time tracking and recording of temperature, humidity, and other environmental conditions to ensure the integrity of perishable goods throughout the supply chain. This process uses sensors and data loggers to detect deviations from required conditions, enabling prompt corrective actions and minimizing spoilage. Explore how advanced cold chain monitoring technologies can enhance product safety and compliance.

Temperature Sensors

Cold chain monitoring involves real-time tracking of temperature sensors to ensure perishable goods remain within specified thermal ranges, preventing spoilage and maintaining product integrity. Cold chain visibility extends beyond monitoring by providing comprehensive insights through sensor data integration, enabling predictive analytics and proactive management across the entire supply chain. Discover how advanced temperature sensors enhance both cold chain monitoring and visibility for optimal product safety.

Data Loggers

Cold chain monitoring primarily involves tracking temperature data through data loggers to ensure product integrity during transportation and storage. Cold chain visibility extends beyond monitoring by providing real-time access, analytics, and alerts via integrated data loggers, allowing proactive decision-making for supply chain management. Explore how advanced data logger technologies enhance cold chain visibility and safeguard sensitive products.

Source and External Links

What Is Cold Chain Monitoring? - ABI Research - Cold chain monitoring tracks temperature-sensitive products using IoT sensors that provide real-time temperature data, enabling fast response to temperature fluctuations during storage and transport to minimize spoilage and waste.

What Is Cold Chain Monitoring? - Samsara - Cold chain monitoring closely tracks temperature and environmental conditions like humidity and light exposure to prevent product degradation, using wireless IoT sensors and alerts to maintain product quality throughout the supply chain.

The Ultimate Guide to Cold Chain Temperature Monitoring - Sensitech - Cold chain monitoring systematically maintains temperature for refrigerated products from production through delivery, using sensors and analytics to ensure compliance and product integrity via real-time data and alerts.

dowidth.com

dowidth.com