Fragmented supply chains involve multiple independent suppliers and manufacturers, increasing complexity and risk but offering flexibility and cost advantages. Vertical integration consolidates production processes within a single company, enhancing control, quality, and efficiency while reducing dependency on external partners. Explore the economic impact of these contrasting strategies to understand their role in global markets.

Why it is important

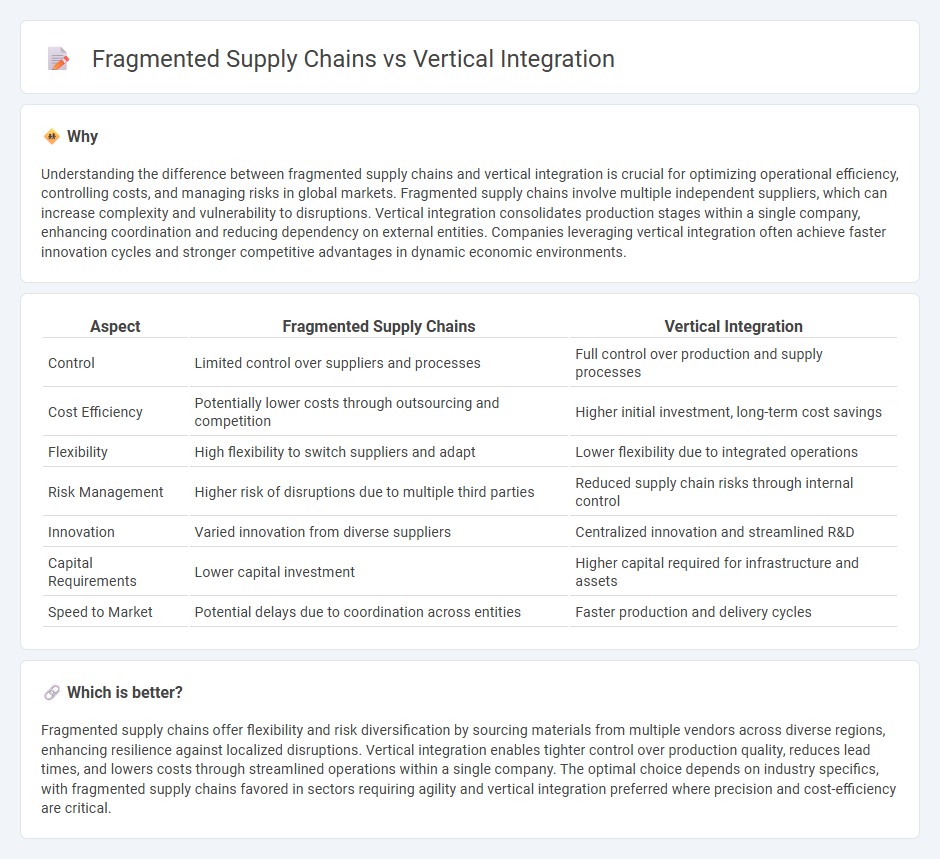

Understanding the difference between fragmented supply chains and vertical integration is crucial for optimizing operational efficiency, controlling costs, and managing risks in global markets. Fragmented supply chains involve multiple independent suppliers, which can increase complexity and vulnerability to disruptions. Vertical integration consolidates production stages within a single company, enhancing coordination and reducing dependency on external entities. Companies leveraging vertical integration often achieve faster innovation cycles and stronger competitive advantages in dynamic economic environments.

Comparison Table

| Aspect | Fragmented Supply Chains | Vertical Integration |

|---|---|---|

| Control | Limited control over suppliers and processes | Full control over production and supply processes |

| Cost Efficiency | Potentially lower costs through outsourcing and competition | Higher initial investment, long-term cost savings |

| Flexibility | High flexibility to switch suppliers and adapt | Lower flexibility due to integrated operations |

| Risk Management | Higher risk of disruptions due to multiple third parties | Reduced supply chain risks through internal control |

| Innovation | Varied innovation from diverse suppliers | Centralized innovation and streamlined R&D |

| Capital Requirements | Lower capital investment | Higher capital required for infrastructure and assets |

| Speed to Market | Potential delays due to coordination across entities | Faster production and delivery cycles |

Which is better?

Fragmented supply chains offer flexibility and risk diversification by sourcing materials from multiple vendors across diverse regions, enhancing resilience against localized disruptions. Vertical integration enables tighter control over production quality, reduces lead times, and lowers costs through streamlined operations within a single company. The optimal choice depends on industry specifics, with fragmented supply chains favored in sectors requiring agility and vertical integration preferred where precision and cost-efficiency are critical.

Connection

Fragmented supply chains increase complexity and risks by involving multiple suppliers across diverse geographic locations, making coordination and control challenging. Vertical integration consolidates production processes within a single organization, enhancing efficiency, reducing dependency on external suppliers, and improving supply chain resilience. This connection highlights how companies use vertical integration to mitigate the vulnerabilities associated with fragmented supply chains in the global economy.

Key Terms

Ownership Structure

Vertical integration involves a company owning multiple stages of its supply chain, enhancing control over production, quality, and cost efficiency. Fragmented supply chains consist of independent entities operating separately, often leading to increased flexibility but reduced coordination and potential inefficiencies. Explore detailed comparisons and strategic implications of ownership structures in supply chains to optimize business operations.

Coordination Costs

Vertical integration reduces coordination costs by consolidating manufacturing, distribution, and sales within a single firm, streamlining communication and decision-making processes. Fragmented supply chains, involving multiple independent firms, often face higher coordination costs due to misaligned incentives, information asymmetry, and contractual complexities. Explore how strategic choices impact operational efficiency and cost management in supply chain design.

Supplier Dependency

Vertical integration reduces supplier dependency by internalizing production processes, ensuring greater control over the supply chain and minimizing risks associated with external suppliers. Fragmented supply chains increase supplier dependency, exposing businesses to disruptions, variability in quality, and delays due to reliance on multiple independent suppliers. Explore the strategic implications of supplier dependency in supply chain management to optimize operational resilience.

Source and External Links

Vertical Integration: Definition, Examples, and Advantages - Vertical integration is a strategic practice where a company controls multiple operations in its supply chain, such as production and distribution, to gain competitive advantage, reduce dependency on suppliers, and better coordinate product flow, although it can be costly and reduce flexibility.

What Is Vertical Integration? Types and Examples (2024) - Shopify - Vertical integration occurs when a company owns two or more stages of its supply chain, with key types including backward integration (controlling suppliers) and forward integration (controlling distribution), aiming to cut costs and improve control over quality and production processes.

How Does Vertical Integration Work? Pros, Cons and Examples - Vertical integration involves ownership across supply chain stages, exemplified by companies like Carnegie Steel, Exxon Mobil, and SpaceX, allowing control over resources and processes to lower costs and improve efficiency across production to retail.

dowidth.com

dowidth.com