The ghost kitchen market is projected to reach $71.4 billion by 2030, driven by rising consumer demand for delivery and takeout services. Robotic food preparation technology enhances operational efficiency by reducing labor costs and ensuring consistent food quality in these kitchens. Explore how integrating robotics can transform revenue streams and scalability in the evolving foodservice economy.

Why it is important

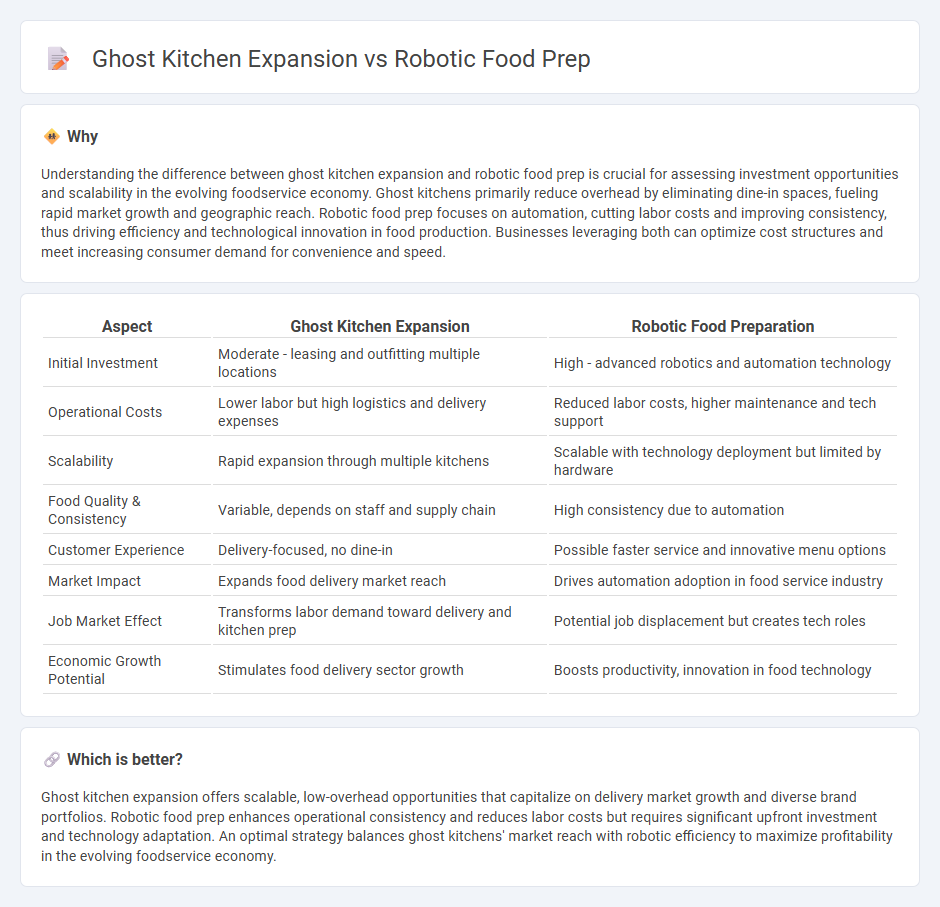

Understanding the difference between ghost kitchen expansion and robotic food prep is crucial for assessing investment opportunities and scalability in the evolving foodservice economy. Ghost kitchens primarily reduce overhead by eliminating dine-in spaces, fueling rapid market growth and geographic reach. Robotic food prep focuses on automation, cutting labor costs and improving consistency, thus driving efficiency and technological innovation in food production. Businesses leveraging both can optimize cost structures and meet increasing consumer demand for convenience and speed.

Comparison Table

| Aspect | Ghost Kitchen Expansion | Robotic Food Preparation |

|---|---|---|

| Initial Investment | Moderate - leasing and outfitting multiple locations | High - advanced robotics and automation technology |

| Operational Costs | Lower labor but high logistics and delivery expenses | Reduced labor costs, higher maintenance and tech support |

| Scalability | Rapid expansion through multiple kitchens | Scalable with technology deployment but limited by hardware |

| Food Quality & Consistency | Variable, depends on staff and supply chain | High consistency due to automation |

| Customer Experience | Delivery-focused, no dine-in | Possible faster service and innovative menu options |

| Market Impact | Expands food delivery market reach | Drives automation adoption in food service industry |

| Job Market Effect | Transforms labor demand toward delivery and kitchen prep | Potential job displacement but creates tech roles |

| Economic Growth Potential | Stimulates food delivery sector growth | Boosts productivity, innovation in food technology |

Which is better?

Ghost kitchen expansion offers scalable, low-overhead opportunities that capitalize on delivery market growth and diverse brand portfolios. Robotic food prep enhances operational consistency and reduces labor costs but requires significant upfront investment and technology adaptation. An optimal strategy balances ghost kitchens' market reach with robotic efficiency to maximize profitability in the evolving foodservice economy.

Connection

The expansion of ghost kitchens drives demand for robotic food preparation by enabling scalable, contactless meal production that reduces labor costs and increases efficiency. Rising consumer preference for delivery services fuels investment in automated cooking technologies, optimizing order fulfillment in virtual restaurant models. Integration of robotics in ghost kitchens accelerates operational output, reshaping the foodservice economy toward automation and digitalization.

Key Terms

Automation

Robotic food preparation enhances efficiency in ghost kitchen operations by reducing labor costs and increasing order accuracy through automated cooking and assembly processes. Ghost kitchens leverage automation technologies such as AI-driven order management systems and robotic arms to scale kitchen capacity while maintaining consistent food quality. Explore how integrating advanced robotics in ghost kitchens drives innovation and transforms food delivery models.

Labor cost reduction

Robotic food preparation significantly reduces labor costs by automating repetitive tasks in kitchen operations, enhancing efficiency and consistency while minimizing human error. Ghost kitchens expand rapidly by leveraging centralized, delivery-only models that cut overhead expenses associated with dining spaces and staff, focusing investments on technology and streamlined workflows. Explore how these innovations are transforming the food service industry and driving cost-effective growth models.

Scalability

Robotic food preparation systems enhance scalability by streamlining cooking processes and reducing labor costs, enabling consistent product quality and faster service in expanding ghost kitchen networks. Ghost kitchens expand rapidly by leveraging flexible, low-overhead spaces that support multiple brands and menu variations, but scaling depends on efficient automation to maintain output levels. Explore how integrating robotics with ghost kitchens revolutionizes scalable food production and delivery.

Source and External Links

Moley Robotics - the world's first fully robotic kitchen - Moley Robotics offers a sophisticated robotic kitchen system with precise, autonomous meal preparation using sensors, motors, and a large recipe database to replicate chef-level cooking with minimal waste and hands-free voice control.

Chef Robotics | AI-enabled Robotic Automation for the Food - Chef Robotics provides AI-powered robotic automation designed to boost food manufacturing efficiency and consistency, addressing labor shortages and improving productivity with flexible, food-safe robotic solutions.

Cooking robots explained: The future of food prep - Standard Bots highlights AI-powered cooking robots like RO1 that deliver fast, precise, and adaptable robotic food preparation, suitable for both startups and large-scale food production with an easy, safe, and cost-effective deployment model.

dowidth.com

dowidth.com