Graphene batteries offer superior energy density and faster charging times compared to traditional Zinc-air batteries, which rely on zinc oxidation and oxygen reduction reactions for power. Zinc-air batteries exhibit longer shelf life and cost-effectiveness but suffer from limited rechargeability and lower power output. Explore the key differences and advancements driving the future of battery technology.

Why it is important

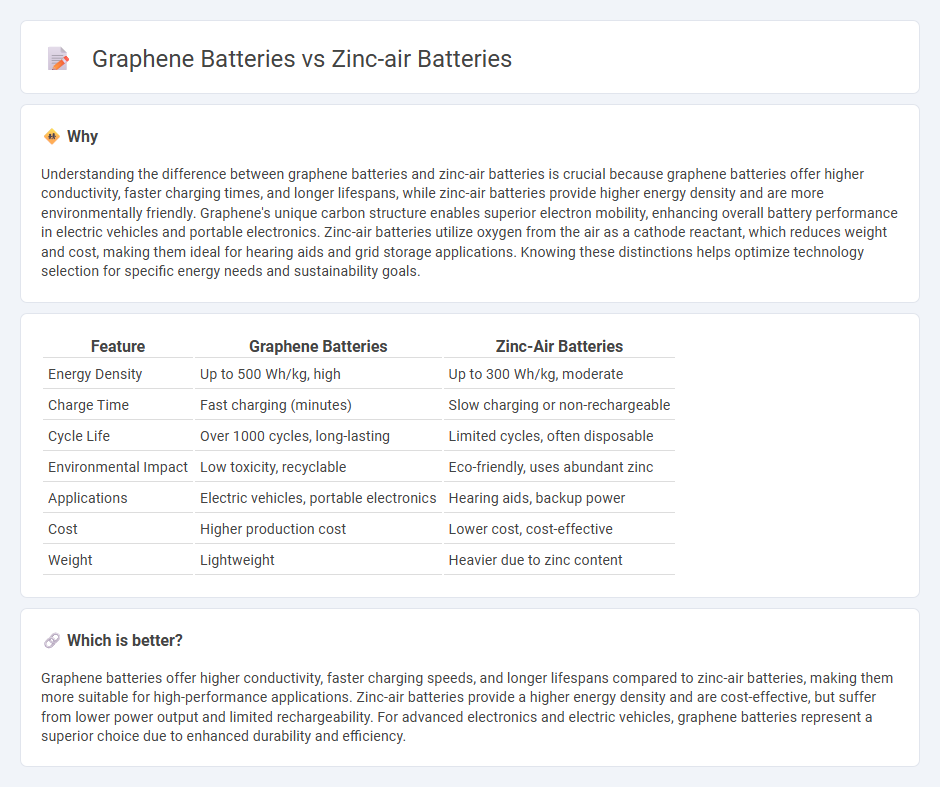

Understanding the difference between graphene batteries and zinc-air batteries is crucial because graphene batteries offer higher conductivity, faster charging times, and longer lifespans, while zinc-air batteries provide higher energy density and are more environmentally friendly. Graphene's unique carbon structure enables superior electron mobility, enhancing overall battery performance in electric vehicles and portable electronics. Zinc-air batteries utilize oxygen from the air as a cathode reactant, which reduces weight and cost, making them ideal for hearing aids and grid storage applications. Knowing these distinctions helps optimize technology selection for specific energy needs and sustainability goals.

Comparison Table

| Feature | Graphene Batteries | Zinc-Air Batteries |

|---|---|---|

| Energy Density | Up to 500 Wh/kg, high | Up to 300 Wh/kg, moderate |

| Charge Time | Fast charging (minutes) | Slow charging or non-rechargeable |

| Cycle Life | Over 1000 cycles, long-lasting | Limited cycles, often disposable |

| Environmental Impact | Low toxicity, recyclable | Eco-friendly, uses abundant zinc |

| Applications | Electric vehicles, portable electronics | Hearing aids, backup power |

| Cost | Higher production cost | Lower cost, cost-effective |

| Weight | Lightweight | Heavier due to zinc content |

Which is better?

Graphene batteries offer higher conductivity, faster charging speeds, and longer lifespans compared to zinc-air batteries, making them more suitable for high-performance applications. Zinc-air batteries provide a higher energy density and are cost-effective, but suffer from lower power output and limited rechargeability. For advanced electronics and electric vehicles, graphene batteries represent a superior choice due to enhanced durability and efficiency.

Connection

Graphene batteries and Zinc-air batteries share a connection through their focus on enhancing energy storage efficiency and capacity by utilizing advanced materials that improve conductivity and charge cycles. Both technologies aim to provide longer-lasting, lightweight, and environmentally friendly alternatives to traditional lithium-ion batteries. The integration of graphene's exceptional electrical properties in Zinc-air battery design can significantly boost performance by increasing conductivity and stability.

Key Terms

Energy Density

Zinc-air batteries typically offer high energy density around 300-400 Wh/kg, making them suitable for applications requiring lightweight and long-lasting power sources. Graphene batteries enhance traditional lithium-ion technology by incorporating graphene materials, potentially achieving energy densities up to 500 Wh/kg with faster charge times and improved thermal management. Explore more to understand the trade-offs and technological advancements shaping the future of high-energy battery systems.

Electrolyte Composition

Zinc-air batteries utilize an aqueous alkaline electrolyte, typically potassium hydroxide, enabling efficient oxygen reduction and zinc oxidation reactions, while graphene batteries often incorporate gel or solid-state electrolytes designed to enhance ionic conductivity and flexibility. The electrolyte composition in zinc-air batteries dictates their high energy density and safety but limits rechargeability, whereas graphene batteries benefit from advanced electrolytes that support rapid charge cycles and improved lifespan. Explore further to understand how electrolyte chemistry influences performance metrics and application suitability in these cutting-edge battery technologies.

Charge Cycle Durability

Zinc-air batteries offer excellent energy density but suffer from limited charge cycle durability, typically lasting a few hundred cycles before significant capacity degradation occurs. Graphene batteries exhibit superior charge cycle durability, often exceeding thousands of cycles due to graphene's enhanced conductivity and mechanical strength, which helps maintain electrode integrity. Explore further to understand which battery technology best suits long-term energy storage needs.

Source and External Links

Zinc-air battery - Zinc-air batteries are metal-air electrochemical cells powered by zinc oxidation with oxygen from the air, offering high energy density and low cost, used in devices from hearing aids to potential electric vehicle batteries.

The Rise of Zinc-Air Batteries in Sustainable Energy Storage - Zinc-air batteries are environmentally friendly, low-cost, and have exceptional specific energy (400-450 Wh/kg) and energy density (1200-1400 Wh/L), making them promising for portable electronics, medical devices, and sustainable energy storage.

Zinc-air batteries: are they ready for prime time? - Zn-air batteries have large theoretical energy density and potentially very low manufacturing costs, but challenges remain in improving stable, rechargeable zinc anodes to fulfill their full potential in commercial applications.

dowidth.com

dowidth.com