Photonic chips use light to process and transmit data at high speeds with low energy consumption, making them essential for next-generation optical communication and computing. MEMS (Microelectromechanical systems) integrate tiny mechanical components with electronics to enable precise sensing and actuation in applications like automotive sensors and medical devices. Discover how the unique advantages of photonic chips and MEMS are shaping the future of technology.

Why it is important

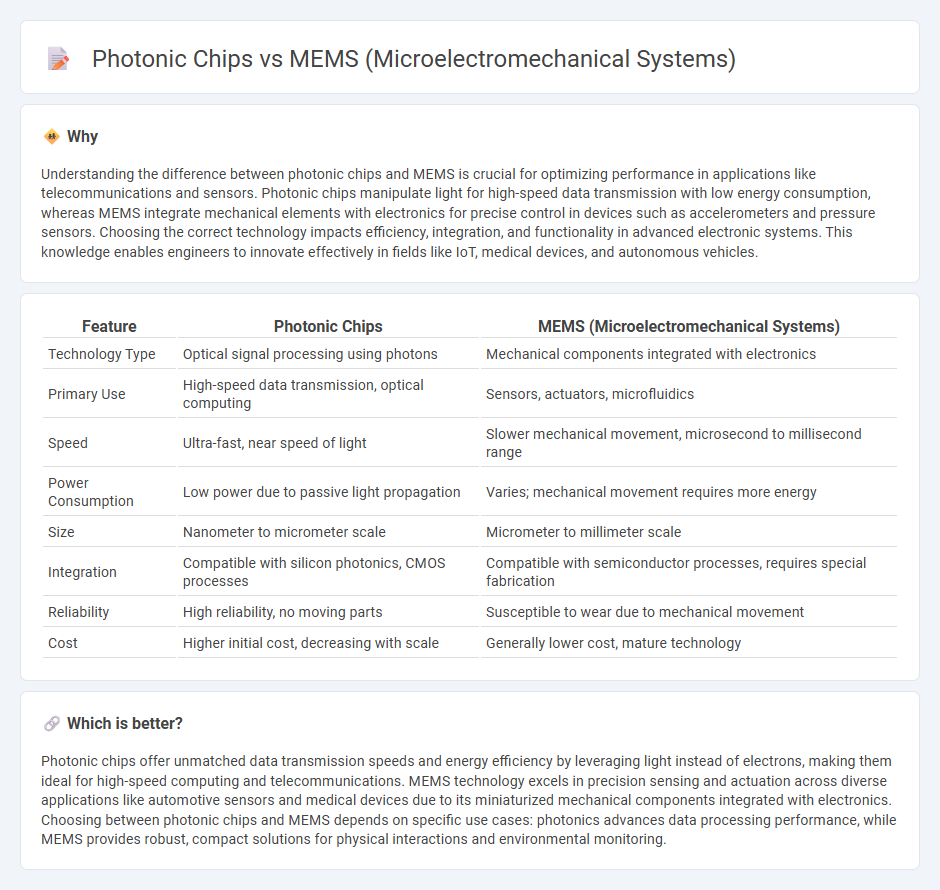

Understanding the difference between photonic chips and MEMS is crucial for optimizing performance in applications like telecommunications and sensors. Photonic chips manipulate light for high-speed data transmission with low energy consumption, whereas MEMS integrate mechanical elements with electronics for precise control in devices such as accelerometers and pressure sensors. Choosing the correct technology impacts efficiency, integration, and functionality in advanced electronic systems. This knowledge enables engineers to innovate effectively in fields like IoT, medical devices, and autonomous vehicles.

Comparison Table

| Feature | Photonic Chips | MEMS (Microelectromechanical Systems) |

|---|---|---|

| Technology Type | Optical signal processing using photons | Mechanical components integrated with electronics |

| Primary Use | High-speed data transmission, optical computing | Sensors, actuators, microfluidics |

| Speed | Ultra-fast, near speed of light | Slower mechanical movement, microsecond to millisecond range |

| Power Consumption | Low power due to passive light propagation | Varies; mechanical movement requires more energy |

| Size | Nanometer to micrometer scale | Micrometer to millimeter scale |

| Integration | Compatible with silicon photonics, CMOS processes | Compatible with semiconductor processes, requires special fabrication |

| Reliability | High reliability, no moving parts | Susceptible to wear due to mechanical movement |

| Cost | Higher initial cost, decreasing with scale | Generally lower cost, mature technology |

Which is better?

Photonic chips offer unmatched data transmission speeds and energy efficiency by leveraging light instead of electrons, making them ideal for high-speed computing and telecommunications. MEMS technology excels in precision sensing and actuation across diverse applications like automotive sensors and medical devices due to its miniaturized mechanical components integrated with electronics. Choosing between photonic chips and MEMS depends on specific use cases: photonics advances data processing performance, while MEMS provides robust, compact solutions for physical interactions and environmental monitoring.

Connection

Photonic chips leverage light-based signals for faster data processing, while MEMS integrate miniature mechanical components with electronics, enabling precise control over optical systems. The integration of MEMS into photonic chips allows for dynamic tuning, switching, and modulation of light signals, enhancing the performance and functionality of optical communication and sensing devices. This synergy drives advancements in high-speed data transfer, miniaturized sensors, and adaptive photonic circuits used in telecommunications and medical imaging.

Key Terms

Miniaturized Sensors (MEMS)

MEMS technology enables highly miniaturized sensors capable of measuring physical parameters such as pressure, acceleration, and temperature with exceptional precision in compact form factors, making them ideal for applications in automotive, healthcare, and consumer electronics. Photonic chips leverage light for data transmission and sensing, offering advantages in speed and bandwidth but often require more complex fabrication processes compared to MEMS sensors. Explore the distinct benefits and use cases of MEMS and photonic chips to understand their impact on the evolving landscape of miniaturized sensor technology.

Light-based Circuits (Photonic chips)

Photonic chips leverage light-based circuits to enable ultra-fast data transmission and low-energy signal processing, outperforming conventional MEMS in bandwidth and speed due to photon's inherent properties. Unlike MEMS, which manipulate mechanical components on a microscale, photonic chips integrate optical components such as waveguides, modulators, and detectors for precise light control within miniaturized platforms. Explore the advancements and potential applications of photonic chips in next-generation communication and computing technologies.

Signal Transduction

MEMS (Microelectromechanical systems) utilize mechanical elements, sensors, and actuators at the microscale to convert physical signals into electrical signals, enabling precise signal transduction through mechanical displacement or pressure changes. Photonic chips leverage light manipulation and optical components to transduce signals by converting electrical inputs into optical outputs, offering high-speed, low-loss data transmission ideal for telecommunications and sensing applications. Explore the advancements in signal transduction technologies by diving deeper into MEMS and photonic chip integration strategies.

Source and External Links

MEMS - Wikipedia - MEMS (micro-electromechanical systems) are microscopic devices combining electronic and mechanical parts, typically sized between 1 and 100 micrometres, fabricated using semiconductor technologies, and designed to interact with their environment through sensors and actuators.

Microelectromechanical systems (MEMS) | EBSCO Research Starters - MEMS are tiny integrated mechanical and electronic devices from millimeters down to submicron sizes, widely used in sensors and actuators in applications such as smartphones, medical devices, and automotive safety, notable for their low power consumption and cost-effectiveness.

Microelectromechanical Systems (MEMS) for Biomedical Applications - MEMS are microscaled precision devices that transduce signals between mechanical and electrical forms, offering advantages like small size, integration capability, low power use, and high sensitivity, making them especially valuable in biomedical and wearable electronics despite fabrication and durability challenges.

dowidth.com

dowidth.com