Modular construction involves creating entire building sections in a factory setting, which are then transported and assembled on-site, offering faster project timelines and enhanced quality control. Prefabricated construction includes a wider range of off-site manufactured components, such as walls or floors, that require more on-site assembly, often resulting in greater customization but longer installation periods. Discover the distinct advantages of modular versus prefabricated construction methods to optimize your real estate investments.

Why it is important

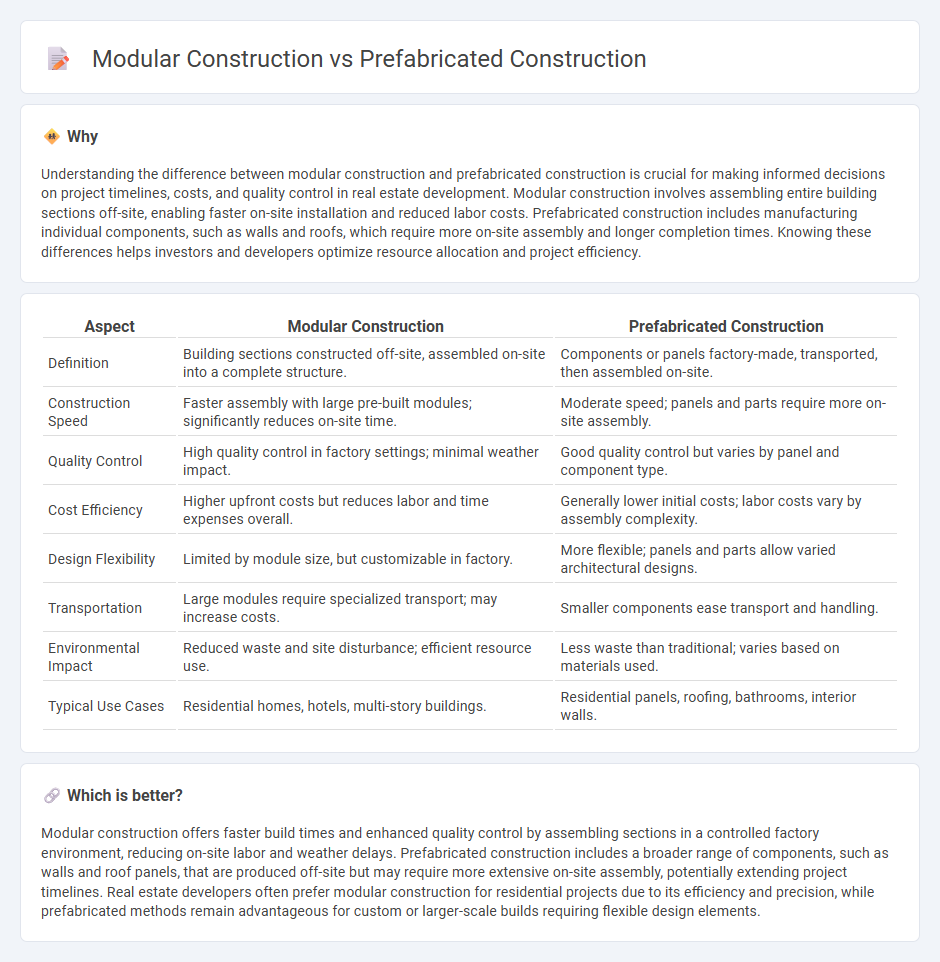

Understanding the difference between modular construction and prefabricated construction is crucial for making informed decisions on project timelines, costs, and quality control in real estate development. Modular construction involves assembling entire building sections off-site, enabling faster on-site installation and reduced labor costs. Prefabricated construction includes manufacturing individual components, such as walls and roofs, which require more on-site assembly and longer completion times. Knowing these differences helps investors and developers optimize resource allocation and project efficiency.

Comparison Table

| Aspect | Modular Construction | Prefabricated Construction |

|---|---|---|

| Definition | Building sections constructed off-site, assembled on-site into a complete structure. | Components or panels factory-made, transported, then assembled on-site. |

| Construction Speed | Faster assembly with large pre-built modules; significantly reduces on-site time. | Moderate speed; panels and parts require more on-site assembly. |

| Quality Control | High quality control in factory settings; minimal weather impact. | Good quality control but varies by panel and component type. |

| Cost Efficiency | Higher upfront costs but reduces labor and time expenses overall. | Generally lower initial costs; labor costs vary by assembly complexity. |

| Design Flexibility | Limited by module size, but customizable in factory. | More flexible; panels and parts allow varied architectural designs. |

| Transportation | Large modules require specialized transport; may increase costs. | Smaller components ease transport and handling. |

| Environmental Impact | Reduced waste and site disturbance; efficient resource use. | Less waste than traditional; varies based on materials used. |

| Typical Use Cases | Residential homes, hotels, multi-story buildings. | Residential panels, roofing, bathrooms, interior walls. |

Which is better?

Modular construction offers faster build times and enhanced quality control by assembling sections in a controlled factory environment, reducing on-site labor and weather delays. Prefabricated construction includes a broader range of components, such as walls and roof panels, that are produced off-site but may require more extensive on-site assembly, potentially extending project timelines. Real estate developers often prefer modular construction for residential projects due to its efficiency and precision, while prefabricated methods remain advantageous for custom or larger-scale builds requiring flexible design elements.

Connection

Modular construction and prefabricated construction are connected through their shared use of off-site manufacturing processes to build components in a controlled factory environment. Both methods improve construction efficiency, reduce waste, and shorten project timelines by assembling pre-made modules on-site. The integration of modular units into prefabricated construction projects enhances scalability and design flexibility in real estate developments.

Key Terms

Off-site fabrication

Prefabricated construction involves manufacturing building components in a factory before transporting them to the site for assembly, optimizing quality control and reducing on-site labor. Modular construction takes prefabrication further by creating entire modules or sections that are fully assembled off-site, enabling faster project timelines and minimizing disruptions. Explore detailed comparisons and project case studies to understand which off-site fabrication method best suits your construction needs.

Assembly method

Prefabricated construction involves manufacturing building components off-site, which are transported and assembled on-site, optimizing time efficiency and reducing labor costs. Modular construction elevates this concept by producing entire volumetric units in factory-controlled settings, enabling faster assembly and higher quality control compared to traditional prefabrication. Explore the distinctions and benefits of these assembly methods to enhance your construction project planning.

Customization level

Prefabricated construction offers moderate customization through pre-made components tailored to specific design requirements, whereas modular construction provides a higher level of customization by assembling fully finished modules that can be easily configured to meet unique architectural styles and functional needs. Modular buildings enable flexible layouts and interior finishes, promoting faster on-site assembly and reduced construction timelines. Explore more about how customization impacts your building project efficiency and design possibilities.

Source and External Links

Prefab Construction: The Risks and Rewards of ... - Prefabrication in construction offers substantial advantages by mitigating risks and uncertainties, allowing for faster project completion through offsite fabrication of components like wall frames.

A guide to prefabrication (and how it's transforming construction) - Prefabrication is a centuries-old practice where building parts are constructed offsite and then transported to the final building site, enhancing sustainability and efficiency in construction.

10 Benefits of Prefab in Construction - Prefabrication involves constructing building components offsite, reducing waste, labor costs, and project timelines by eliminating traditional on-site construction methods.

dowidth.com

dowidth.com