Modular homes are factory-built structures assembled in sections and transported to the site for quick installation, offering durability and design flexibility. Panelized homes consist of pre-cut wall panels manufactured off-site, allowing for faster construction and cost efficiency in customization. Explore the advantages and applications of modular and panelized homes to determine the best fit for your real estate project.

Why it is important

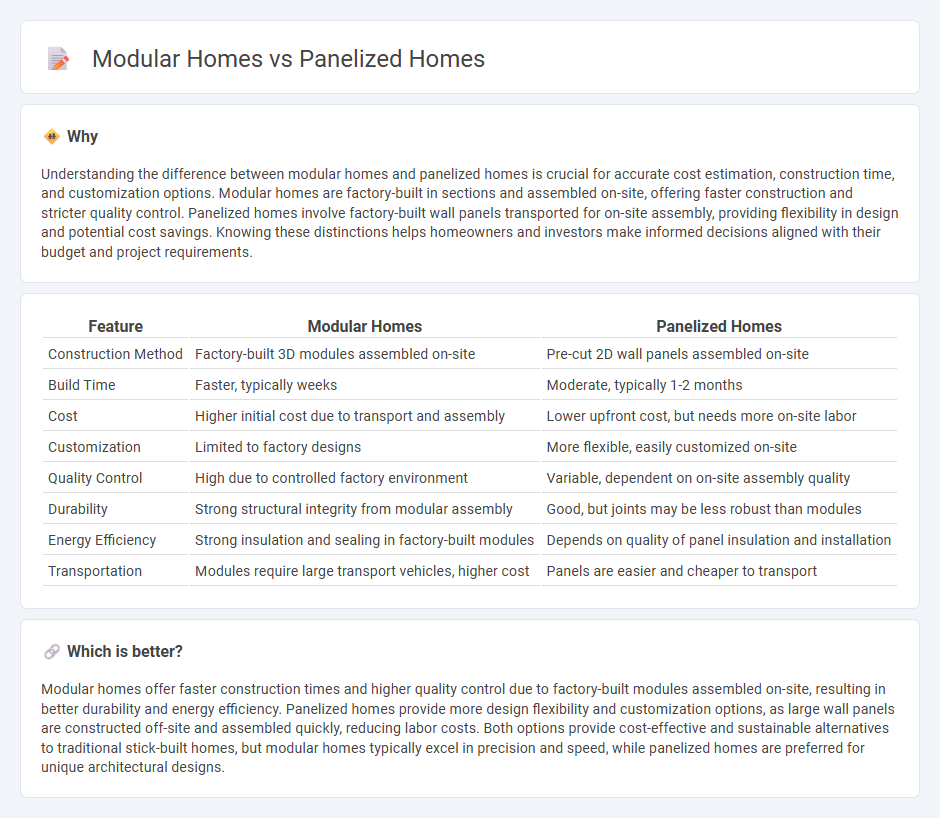

Understanding the difference between modular homes and panelized homes is crucial for accurate cost estimation, construction time, and customization options. Modular homes are factory-built in sections and assembled on-site, offering faster construction and stricter quality control. Panelized homes involve factory-built wall panels transported for on-site assembly, providing flexibility in design and potential cost savings. Knowing these distinctions helps homeowners and investors make informed decisions aligned with their budget and project requirements.

Comparison Table

| Feature | Modular Homes | Panelized Homes |

|---|---|---|

| Construction Method | Factory-built 3D modules assembled on-site | Pre-cut 2D wall panels assembled on-site |

| Build Time | Faster, typically weeks | Moderate, typically 1-2 months |

| Cost | Higher initial cost due to transport and assembly | Lower upfront cost, but needs more on-site labor |

| Customization | Limited to factory designs | More flexible, easily customized on-site |

| Quality Control | High due to controlled factory environment | Variable, dependent on on-site assembly quality |

| Durability | Strong structural integrity from modular assembly | Good, but joints may be less robust than modules |

| Energy Efficiency | Strong insulation and sealing in factory-built modules | Depends on quality of panel insulation and installation |

| Transportation | Modules require large transport vehicles, higher cost | Panels are easier and cheaper to transport |

Which is better?

Modular homes offer faster construction times and higher quality control due to factory-built modules assembled on-site, resulting in better durability and energy efficiency. Panelized homes provide more design flexibility and customization options, as large wall panels are constructed off-site and assembled quickly, reducing labor costs. Both options provide cost-effective and sustainable alternatives to traditional stick-built homes, but modular homes typically excel in precision and speed, while panelized homes are preferred for unique architectural designs.

Connection

Modular homes and panelized homes are connected by their use of prefabricated construction techniques that enhance building efficiency and reduce onsite labor. Both methods involve factory-built components; modular homes are constructed as complete sections or modules, while panelized homes consist of flat panels like walls and floors assembled at the site. This approach significantly shortens construction time, improves quality control, and minimizes material waste compared to traditional building methods.

Key Terms

Construction Method

Panelized homes utilize factory-built wall panels transported to the site for assembly, significantly reducing on-site labor and construction time. Modular homes consist of fully constructed sections or modules built indoors under controlled conditions, which are then transported and assembled on a foundation, ensuring quality and consistency. Discover the detailed differences in construction methods to choose the best option for your project.

Factory-Built Components

Panelized homes use factory-built wall, floor, and roof panels that are transported to the job site for assembly, offering precise construction and reduced on-site labor. Modular homes consist of fully constructed sections or modules built in a factory, which are then transported and assembled on-site, ensuring higher quality control and faster build times. Explore the benefits and differences of factory-built components to determine which option suits your housing project best.

On-Site Assembly

Panelized homes feature pre-cut wall panels transported to the site for rapid on-site assembly, reducing construction time and minimizing waste. Modular homes arrive as fully constructed sections that require efficient on-site stacking and connection, enabling faster project completion with consistent quality control. Explore more about how on-site assembly methods impact costs and construction timelines in both housing options.

Source and External Links

Panelized Construction - Momo Homes - Panelized homes are prefabricated structures where major components like walls, floors, and roofs are built off-site in a factory, then transported and assembled at the construction site, offering improved quality, efficiency, and design flexibility compared to traditional stick-built homes.

Panelized Homes: Your Questions Answered - A panelized house is built from pre-engineered wall, roof, and floor sections produced in a factory, shipped to the site, and assembled there, resulting in better airtightness and often lower costs than conventional stick framing, with installation typically handled by a general contractor.

What is a Panelized Home and Its Benefits? - Panelized home systems deliver engineered floor systems, interior and exterior walls, and roof trusses to the job site after the foundation is prepared, combining traditional construction methods with modern technology for energy-efficient, durable, and customizable homes.

dowidth.com

dowidth.com