Modular construction streamlines home building by assembling pre-fabricated sections off-site, reducing construction time and labor costs. 3D printed homes utilize advanced additive manufacturing technology to create intricate designs with minimal material waste and enhanced customization. Discover how these innovative methods are transforming the real estate landscape and offering sustainable housing solutions.

Why it is important

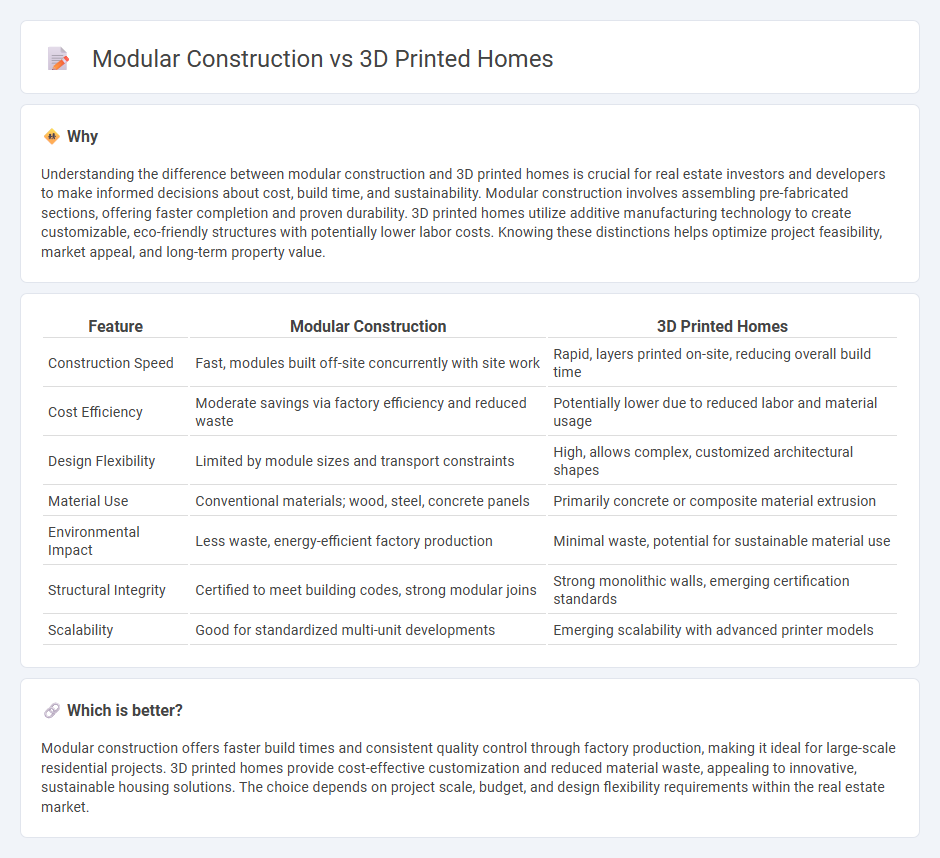

Understanding the difference between modular construction and 3D printed homes is crucial for real estate investors and developers to make informed decisions about cost, build time, and sustainability. Modular construction involves assembling pre-fabricated sections, offering faster completion and proven durability. 3D printed homes utilize additive manufacturing technology to create customizable, eco-friendly structures with potentially lower labor costs. Knowing these distinctions helps optimize project feasibility, market appeal, and long-term property value.

Comparison Table

| Feature | Modular Construction | 3D Printed Homes |

|---|---|---|

| Construction Speed | Fast, modules built off-site concurrently with site work | Rapid, layers printed on-site, reducing overall build time |

| Cost Efficiency | Moderate savings via factory efficiency and reduced waste | Potentially lower due to reduced labor and material usage |

| Design Flexibility | Limited by module sizes and transport constraints | High, allows complex, customized architectural shapes |

| Material Use | Conventional materials; wood, steel, concrete panels | Primarily concrete or composite material extrusion |

| Environmental Impact | Less waste, energy-efficient factory production | Minimal waste, potential for sustainable material use |

| Structural Integrity | Certified to meet building codes, strong modular joins | Strong monolithic walls, emerging certification standards |

| Scalability | Good for standardized multi-unit developments | Emerging scalability with advanced printer models |

Which is better?

Modular construction offers faster build times and consistent quality control through factory production, making it ideal for large-scale residential projects. 3D printed homes provide cost-effective customization and reduced material waste, appealing to innovative, sustainable housing solutions. The choice depends on project scale, budget, and design flexibility requirements within the real estate market.

Connection

Modular construction and 3D printed homes both revolutionize the real estate industry by significantly reducing build times and construction costs through prefabrication and automation technologies. These innovative building methods enhance sustainability by minimizing material waste and enabling precise resource management, aligning with growing demand for eco-friendly housing solutions. Integration of modular components with 3D printed elements offers flexible design possibilities, promoting scalability and customization in residential developments.

Key Terms

Construction Speed

3D printed homes dramatically reduce construction time by fabricating walls and structural components layer-by-layer directly on-site, often completing builds in days instead of weeks or months typical of traditional methods. Modular construction accelerates the building process through prefabricated modules assembled off-site simultaneously with site preparation, enabling faster overall project completion than conventional construction. Explore detailed comparisons to understand which method best suits your construction speed requirements.

Customization

3D printed homes offer unparalleled customization by allowing intricate designs and unique architectural features tailored to individual preferences, which traditional modular construction often limits due to standardized components. Modular homes excel in efficiency and consistency but may lack the flexibility to accommodate highly personalized floor plans or innovative exterior aesthetics. Explore the latest advancements in 3D printed housing to discover how customization is revolutionizing homebuilding.

Cost-Efficiency

3D printed homes lower labor costs by automating construction and reducing waste through precise material usage, resulting in significant savings compared to traditional building methods. Modular construction offers cost-efficiency via factory-controlled processes, shorter build times, and economies of scale, though it involves transportation and assembly expenses. Explore detailed comparisons to understand which method best suits your budget and project goals.

Source and External Links

3D-Printed Houses: 12 Top Examples - 3D printed homes are life-size houses built layer by layer with industrial 3D printing technology, typically from a cement mix, enabling construction within hours at much lower cost and waste than traditional methods; this technology is rapidly growing and even funded by NASA for off-world infrastructure.

3D-Printed Homes: A guide to time, cost, and ownership - Starting from examples like China's 2014 3D-printed housing, modern 3D homes use large printers to deposit cement-based or sustainable materials layer by layer from digital blueprints, allowing for fast construction and potential customization at lower cost.

Can 3D-printed homes withstand a changing climate? - Companies like Icon are building entire 3D printed housing communities using robotic printers that layer concrete reinforced with steel, promising houses that are both resilient to climate challenges and transformative to construction jobs.

dowidth.com

dowidth.com