Pick and pack logistics involves selecting individual items and packing them immediately for shipment, offering high accuracy and flexibility for smaller orders. Wave picking organizes orders into batches or waves processed at specific times to optimize labor and equipment efficiency in high-volume environments. Explore the advantages and best use cases of each method to enhance your warehouse operations.

Why it is important

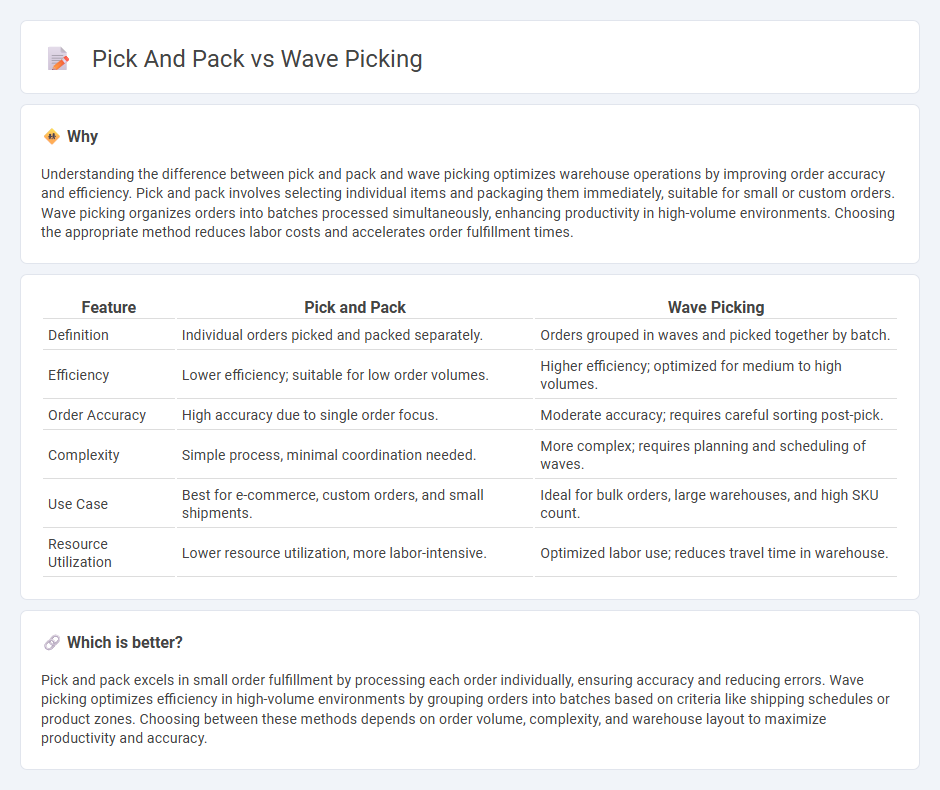

Understanding the difference between pick and pack and wave picking optimizes warehouse operations by improving order accuracy and efficiency. Pick and pack involves selecting individual items and packaging them immediately, suitable for small or custom orders. Wave picking organizes orders into batches processed simultaneously, enhancing productivity in high-volume environments. Choosing the appropriate method reduces labor costs and accelerates order fulfillment times.

Comparison Table

| Feature | Pick and Pack | Wave Picking |

|---|---|---|

| Definition | Individual orders picked and packed separately. | Orders grouped in waves and picked together by batch. |

| Efficiency | Lower efficiency; suitable for low order volumes. | Higher efficiency; optimized for medium to high volumes. |

| Order Accuracy | High accuracy due to single order focus. | Moderate accuracy; requires careful sorting post-pick. |

| Complexity | Simple process, minimal coordination needed. | More complex; requires planning and scheduling of waves. |

| Use Case | Best for e-commerce, custom orders, and small shipments. | Ideal for bulk orders, large warehouses, and high SKU count. |

| Resource Utilization | Lower resource utilization, more labor-intensive. | Optimized labor use; reduces travel time in warehouse. |

Which is better?

Pick and pack excels in small order fulfillment by processing each order individually, ensuring accuracy and reducing errors. Wave picking optimizes efficiency in high-volume environments by grouping orders into batches based on criteria like shipping schedules or product zones. Choosing between these methods depends on order volume, complexity, and warehouse layout to maximize productivity and accuracy.

Connection

Pick and pack and wave picking are interconnected warehouse processes designed to enhance order fulfillment efficiency. In wave picking, orders are grouped into waves based on specific criteria such as shipping schedules or product types to optimize picker movement. These waves guide the pick and pack operation, where selected items are gathered and packed for shipment, streamlining the entire logistics workflow.

Key Terms

Batch Processing

Wave picking consolidates multiple orders into a single picking wave, enhancing efficiency by reducing travel time and improving batch processing speed in warehouses. In contrast, pick and pack handles orders individually, which may slow down batch processing due to frequent task switching and less optimized workflows. Explore the detailed benefits and use cases of wave picking versus pick and pack to optimize your warehouse operations.

Order Consolidation

Wave picking organizes orders into batches or waves based on similar criteria such as shipping schedules or product types, enhancing order consolidation by grouping items efficiently for simultaneous picking. Pick and pack processes each individual order separately, which can limit order consolidation opportunities but allows for precise and tailored packing for each customer. Discover how optimizing these methods impacts warehouse efficiency and customer satisfaction.

Sequential Packing

Wave picking organizes orders into batches based on scheduled waves, optimizing sequential packing by grouping similar items for efficient workflow. Pick and pack processes orders individually, which can slow down packing due to lack of sequencing and increased item handling. Explore how sequential packing techniques improve order fulfillment speed and accuracy through wave picking strategies.

Source and External Links

Wave picking explained: strategies, benefits, and best practices - Wave picking is a warehouse fulfillment method where orders are grouped into batches or "waves" and picked together to improve efficiency and reduce wasted movement, with strategies like single-order, multi-order, and zone-based picking available depending on operation size and priorities.

What Is Wave Picking? How It Works, Methods & Tips - NetSuite - Also known as cluster picking, wave picking releases specific orders to the floor in batches based on common factors such as delivery time, product type, or destination, requiring a strong warehouse management system (WMS) to optimize the process and ensure orders meet delivery commitments.

Warehouse Wave Picking: Guide, Benefits, & Use Cases - ShipBob - Instead of picking each order as it arrives, orders are accumulated and grouped by shared attributes like shipping date or carrier, then released in periodic "waves" for pickers to fulfill multiple orders in a single trip through the warehouse.

dowidth.com

dowidth.com