Predictive fleet maintenance leverages real-time data and analytics to anticipate vehicle issues before they cause breakdowns, enhancing operational efficiency and reducing downtime in logistics. Supply chain visibility offers comprehensive tracking of goods and inventory across all stages, enabling better decision-making and responsiveness to disruptions. Discover how integrating these technologies can transform your logistics strategy and boost overall performance.

Why it is important

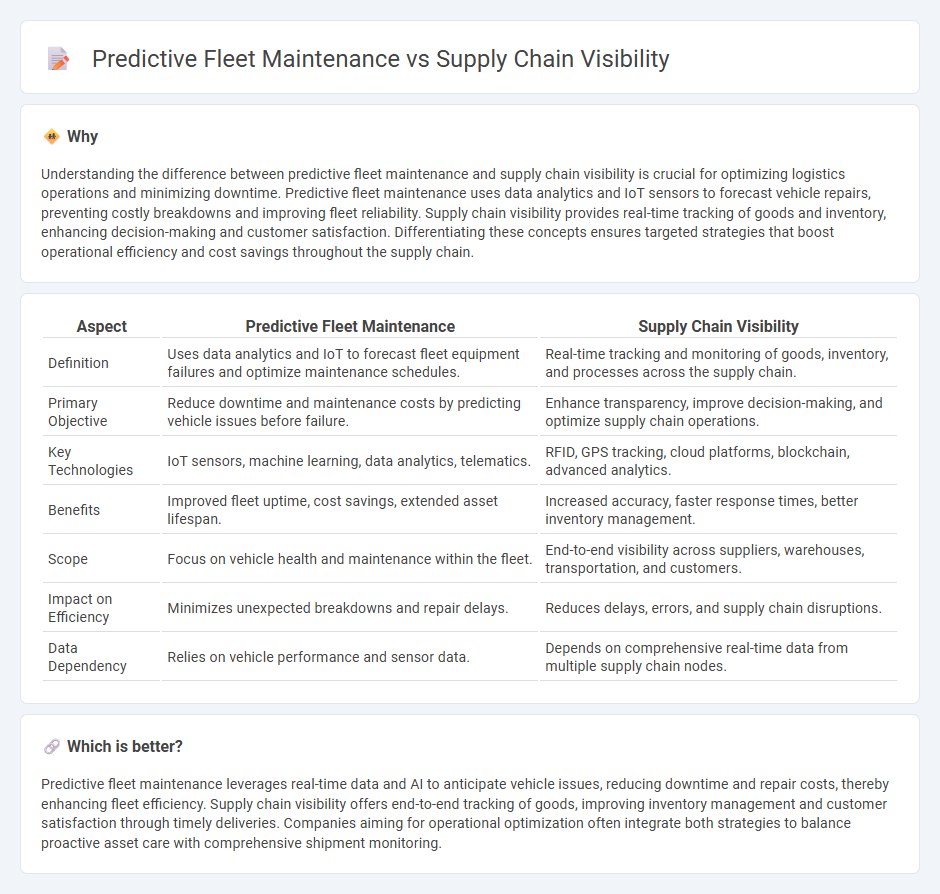

Understanding the difference between predictive fleet maintenance and supply chain visibility is crucial for optimizing logistics operations and minimizing downtime. Predictive fleet maintenance uses data analytics and IoT sensors to forecast vehicle repairs, preventing costly breakdowns and improving fleet reliability. Supply chain visibility provides real-time tracking of goods and inventory, enhancing decision-making and customer satisfaction. Differentiating these concepts ensures targeted strategies that boost operational efficiency and cost savings throughout the supply chain.

Comparison Table

| Aspect | Predictive Fleet Maintenance | Supply Chain Visibility |

|---|---|---|

| Definition | Uses data analytics and IoT to forecast fleet equipment failures and optimize maintenance schedules. | Real-time tracking and monitoring of goods, inventory, and processes across the supply chain. |

| Primary Objective | Reduce downtime and maintenance costs by predicting vehicle issues before failure. | Enhance transparency, improve decision-making, and optimize supply chain operations. |

| Key Technologies | IoT sensors, machine learning, data analytics, telematics. | RFID, GPS tracking, cloud platforms, blockchain, advanced analytics. |

| Benefits | Improved fleet uptime, cost savings, extended asset lifespan. | Increased accuracy, faster response times, better inventory management. |

| Scope | Focus on vehicle health and maintenance within the fleet. | End-to-end visibility across suppliers, warehouses, transportation, and customers. |

| Impact on Efficiency | Minimizes unexpected breakdowns and repair delays. | Reduces delays, errors, and supply chain disruptions. |

| Data Dependency | Relies on vehicle performance and sensor data. | Depends on comprehensive real-time data from multiple supply chain nodes. |

Which is better?

Predictive fleet maintenance leverages real-time data and AI to anticipate vehicle issues, reducing downtime and repair costs, thereby enhancing fleet efficiency. Supply chain visibility offers end-to-end tracking of goods, improving inventory management and customer satisfaction through timely deliveries. Companies aiming for operational optimization often integrate both strategies to balance proactive asset care with comprehensive shipment monitoring.

Connection

Predictive fleet maintenance relies heavily on real-time supply chain visibility to monitor vehicle conditions and anticipate potential failures before they disrupt operations. Integrating data from telematics, IoT sensors, and supply chain management systems enables accurate forecasting of maintenance needs, reducing downtime and optimizing asset utilization. Enhanced visibility throughout the supply chain allows for proactive scheduling and resource allocation, improving overall logistics efficiency and reliability.

Key Terms

**Supply Chain Visibility:**

Supply chain visibility involves real-time tracking, monitoring, and data integration across all supply chain stages to enhance operational efficiency and reduce risks. Technologies such as IoT sensors, blockchain, and AI-driven analytics provide comprehensive insights into inventory levels, transportation status, and demand fluctuations. Explore how supply chain visibility transforms logistics performance and decision-making for competitive advantage.

Real-time Tracking

Real-time tracking enhances supply chain visibility by providing accurate, up-to-the-minute data on shipment locations and status, enabling faster decision-making and improved operational efficiency. Predictive fleet maintenance leverages real-time vehicle diagnostics and sensor data to forecast maintenance needs, reducing downtime and optimizing fleet performance. Explore how integrating real-time tracking technologies transforms both supply chain operations and fleet maintenance strategies.

Data Integration

Supply chain visibility leverages comprehensive data integration to provide real-time tracking and status updates across the entire logistics network, enhancing decision-making and operational efficiency. Predictive fleet maintenance depends heavily on integrating sensor data, historical maintenance records, and real-time vehicle diagnostics to forecast potential failures and schedule timely interventions. Explore how advanced data integration techniques transform both supply chain transparency and predictive maintenance strategies to optimize performance.

Source and External Links

What is Supply Chain Visibility? Meaning and Definition - GEP - Supply chain visibility involves tracking inventory as it moves through the supply chain, enabling real-time monitoring and data-driven decision-making.

What is Supply Chain Visibility? - Tibco - Supply chain visibility tracks products from raw materials to customers, allowing organizations to identify inefficiencies and improve customer satisfaction.

What Is Supply Chain Visibility (SCV)? Definition & Examples - Supply chain visibility involves tracking components and products throughout the supply chain, enhancing operational transparency and efficiency.

dowidth.com

dowidth.com