Shared warehousing offers cost efficiency and flexibility by allowing multiple businesses to store goods in the same facility, optimizing space utilization and reducing overhead costs. Dedicated warehousing provides exclusive use of storage space tailored to a single company's specific needs, enhancing control over inventory management and security. Explore the advantages and suitable applications of shared versus dedicated warehousing to optimize your supply chain strategy.

Why it is important

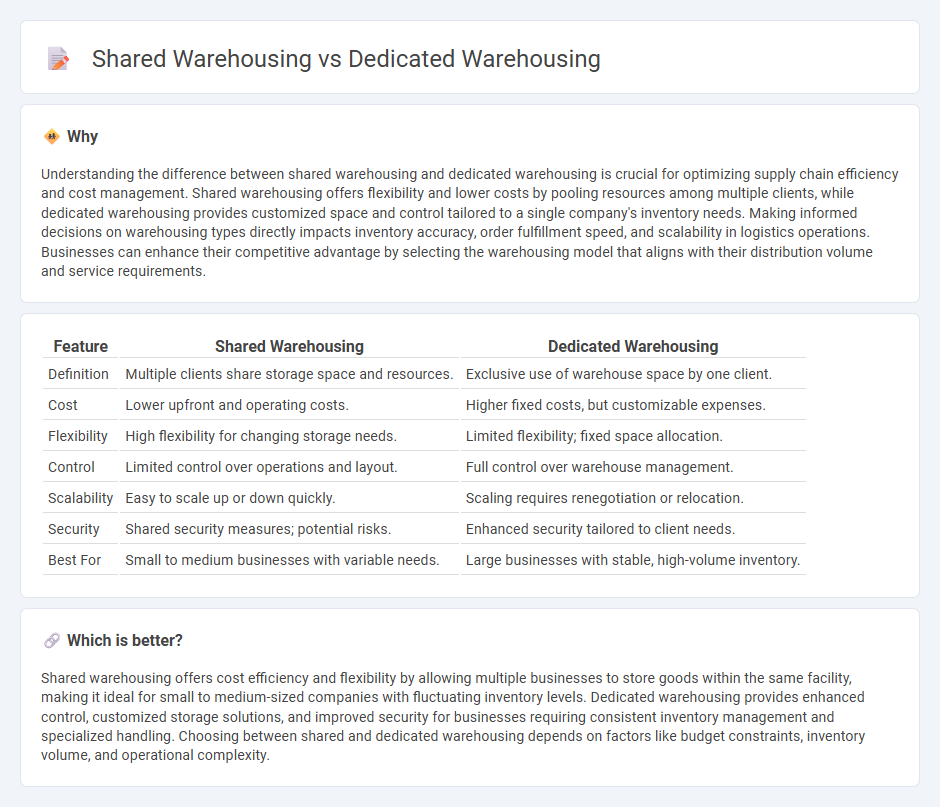

Understanding the difference between shared warehousing and dedicated warehousing is crucial for optimizing supply chain efficiency and cost management. Shared warehousing offers flexibility and lower costs by pooling resources among multiple clients, while dedicated warehousing provides customized space and control tailored to a single company's inventory needs. Making informed decisions on warehousing types directly impacts inventory accuracy, order fulfillment speed, and scalability in logistics operations. Businesses can enhance their competitive advantage by selecting the warehousing model that aligns with their distribution volume and service requirements.

Comparison Table

| Feature | Shared Warehousing | Dedicated Warehousing |

|---|---|---|

| Definition | Multiple clients share storage space and resources. | Exclusive use of warehouse space by one client. |

| Cost | Lower upfront and operating costs. | Higher fixed costs, but customizable expenses. |

| Flexibility | High flexibility for changing storage needs. | Limited flexibility; fixed space allocation. |

| Control | Limited control over operations and layout. | Full control over warehouse management. |

| Scalability | Easy to scale up or down quickly. | Scaling requires renegotiation or relocation. |

| Security | Shared security measures; potential risks. | Enhanced security tailored to client needs. |

| Best For | Small to medium businesses with variable needs. | Large businesses with stable, high-volume inventory. |

Which is better?

Shared warehousing offers cost efficiency and flexibility by allowing multiple businesses to store goods within the same facility, making it ideal for small to medium-sized companies with fluctuating inventory levels. Dedicated warehousing provides enhanced control, customized storage solutions, and improved security for businesses requiring consistent inventory management and specialized handling. Choosing between shared and dedicated warehousing depends on factors like budget constraints, inventory volume, and operational complexity.

Connection

Shared warehousing and dedicated warehousing are connected through their roles in optimizing supply chain efficiency by managing inventory storage and distribution. Shared warehousing offers flexible, cost-effective space for multiple clients, while dedicated warehousing provides exclusive storage tailored to a single company's specific needs. Both approaches complement each other by allowing businesses to balance scalability with control in logistics operations.

Key Terms

Exclusivity

Dedicated warehousing offers exclusive storage space tailored to a single client's inventory, ensuring personalized management, enhanced security, and customized operational control. Shared warehousing involves multiple clients utilizing a common facility, optimizing costs but potentially reducing individual control and exclusivity. Discover the critical factors shaping your ideal warehousing solution by exploring more about exclusivity in storage options.

Cost structure

Dedicated warehousing involves fixed costs such as lease, utilities, and labor, allowing businesses to have complete control over operations but requiring higher upfront investment. Shared warehousing offers a flexible cost structure with variable expenses based on usage, reducing financial risk and optimizing operational efficiency for smaller or seasonal businesses. Explore deeper insights into cost benefits and scenarios for choosing between dedicated and shared warehousing.

Flexibility

Dedicated warehousing offers exclusive storage space tailored to specific business needs, providing higher flexibility in inventory management and operational control compared to shared warehousing. Shared warehousing, while cost-effective, requires businesses to adapt to predefined logistical schedules and limited customization due to space and resource sharing. Explore how flexibly aligned warehousing options can optimize your supply chain by learning more about tailored solutions.

Source and External Links

What is Dedicated Warehousing and How does it Work? - Dedicated warehousing is a strategic logistics approach where a business outsources its entire storage and distribution to a third-party logistics provider who dedicates resources exclusively to that business, offering customized, transparent cost structures and tailored inventory management services.

Warehousing Options: Dedicated vs. Multi-Client vs. Public - Dedicated warehousing involves outsourcing the management of a large, exclusive facility customized for one business's product flow and demand, providing pricing transparency and specialized services like quality inspection and labeling often not available in shared or public warehouses.

5 Ways Dedicated Warehousing Can Give Your Business a Competitive Edge - Dedicated warehousing offers customized solutions specifically aligned to your business needs, improving inventory accuracy, reducing errors, and speeding up order fulfillment to enhance customer satisfaction and operational efficiency.

dowidth.com

dowidth.com