Ghost warehousing, also known as dark warehousing, leverages third-party facilities optimized for flexibility and cost-efficiency, often supported by advanced inventory management systems. In-house warehousing involves managing storage and distribution within a company's owned or leased property, providing direct control but requiring higher capital investment and operational resources. Explore the advantages and challenges of each to optimize your supply chain strategy.

Why it is important

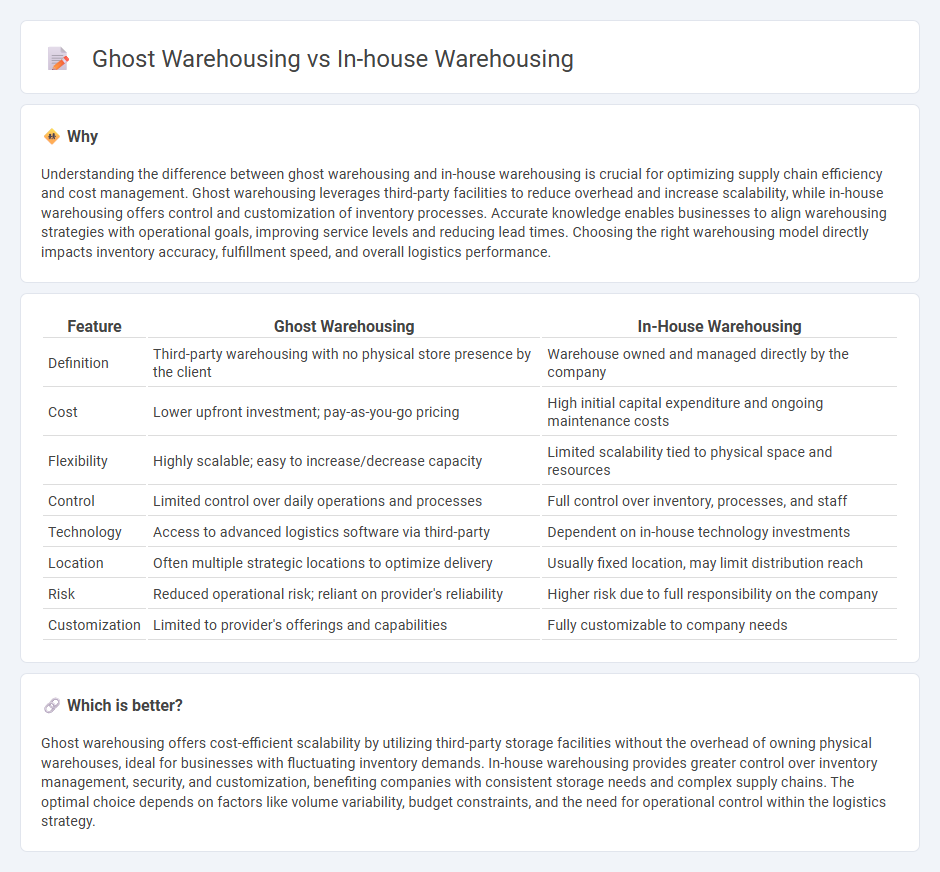

Understanding the difference between ghost warehousing and in-house warehousing is crucial for optimizing supply chain efficiency and cost management. Ghost warehousing leverages third-party facilities to reduce overhead and increase scalability, while in-house warehousing offers control and customization of inventory processes. Accurate knowledge enables businesses to align warehousing strategies with operational goals, improving service levels and reducing lead times. Choosing the right warehousing model directly impacts inventory accuracy, fulfillment speed, and overall logistics performance.

Comparison Table

| Feature | Ghost Warehousing | In-House Warehousing |

|---|---|---|

| Definition | Third-party warehousing with no physical store presence by the client | Warehouse owned and managed directly by the company |

| Cost | Lower upfront investment; pay-as-you-go pricing | High initial capital expenditure and ongoing maintenance costs |

| Flexibility | Highly scalable; easy to increase/decrease capacity | Limited scalability tied to physical space and resources |

| Control | Limited control over daily operations and processes | Full control over inventory, processes, and staff |

| Technology | Access to advanced logistics software via third-party | Dependent on in-house technology investments |

| Location | Often multiple strategic locations to optimize delivery | Usually fixed location, may limit distribution reach |

| Risk | Reduced operational risk; reliant on provider's reliability | Higher risk due to full responsibility on the company |

| Customization | Limited to provider's offerings and capabilities | Fully customizable to company needs |

Which is better?

Ghost warehousing offers cost-efficient scalability by utilizing third-party storage facilities without the overhead of owning physical warehouses, ideal for businesses with fluctuating inventory demands. In-house warehousing provides greater control over inventory management, security, and customization, benefiting companies with consistent storage needs and complex supply chains. The optimal choice depends on factors like volume variability, budget constraints, and the need for operational control within the logistics strategy.

Connection

Ghost warehousing and in-house warehousing are interconnected through their roles in inventory management and operational efficiency within supply chains. Ghost warehousing involves utilizing third-party warehouse space without physical presence, complementing in-house warehousing which relies on company-owned facilities to store and manage goods. Integrating both approaches enables businesses to optimize storage capacity, reduce costs, and enhance flexibility in logistics operations.

Key Terms

Inventory Control

In-house warehousing offers direct inventory control, allowing businesses to manage stock levels, track assets, and respond quickly to supply chain fluctuations within their own facility. Ghost warehousing leverages third-party logistics providers, utilizing real-time data integration and advanced tracking technologies to optimize inventory accuracy without the overhead of physical storage management. Explore the benefits and challenges of both models to determine the best approach for enhancing your inventory control strategy.

Fulfillment Speed

In-house warehousing offers direct control over inventory management, enabling faster order processing and fulfillment speed due to proximity and immediate access to stock. Ghost warehousing leverages third-party networks and automation technologies to optimize delivery routes and reduce transit times without maintaining physical inventory on-site. Explore how these warehousing models impact your fulfillment strategy and customer satisfaction for a competitive edge.

Overhead Costs

In-house warehousing involves direct management of storage facilities, requiring investment in rent, utilities, labor, and maintenance, which significantly increases overhead costs. Ghost warehousing leverages third-party logistics providers to handle storage and fulfillment, reducing fixed expenses and converting overhead to variable costs aligned with inventory needs. Explore deeper insights on how these models impact overall supply chain efficiency and cost control strategies.

Source and External Links

In-House Warehousing Services Definition and Meaning - In-house warehousing refers to managing storage, handling, and distribution of goods within a company's own facilities, giving businesses full control over inventory and order fulfillment processes, improving efficiency and flexibility.

Outsourced vs inhouse warehousing: Which is right for your business? - In-house warehousing offers complete control, operational flexibility, and the ability to strategically design warehouse facilities tailored to specific business needs without reliance on third-party providers.

How to Shift From In-House Warehouse to a 3PL - Cahoot.ai - In-house warehousing means managing logistics operations within your own facilities rather than outsourcing, providing full control of goods but also requiring sufficient internal resources to handle all logistics tasks effectively.

dowidth.com

dowidth.com