Reverse logistics solutions focus on efficiently managing product returns, refurbishments, and recycling to minimize waste and recover value, while distribution center operations prioritize the storage, sorting, and forward movement of goods to meet customer demand promptly. Advanced technologies like RFID tracking and automated sorting systems enhance accuracy and speed in both processes, but reverse logistics demands greater emphasis on handling diverse return conditions and compliance requirements. Explore how integrating these strategies can optimize supply chain performance and sustainability.

Why it is important

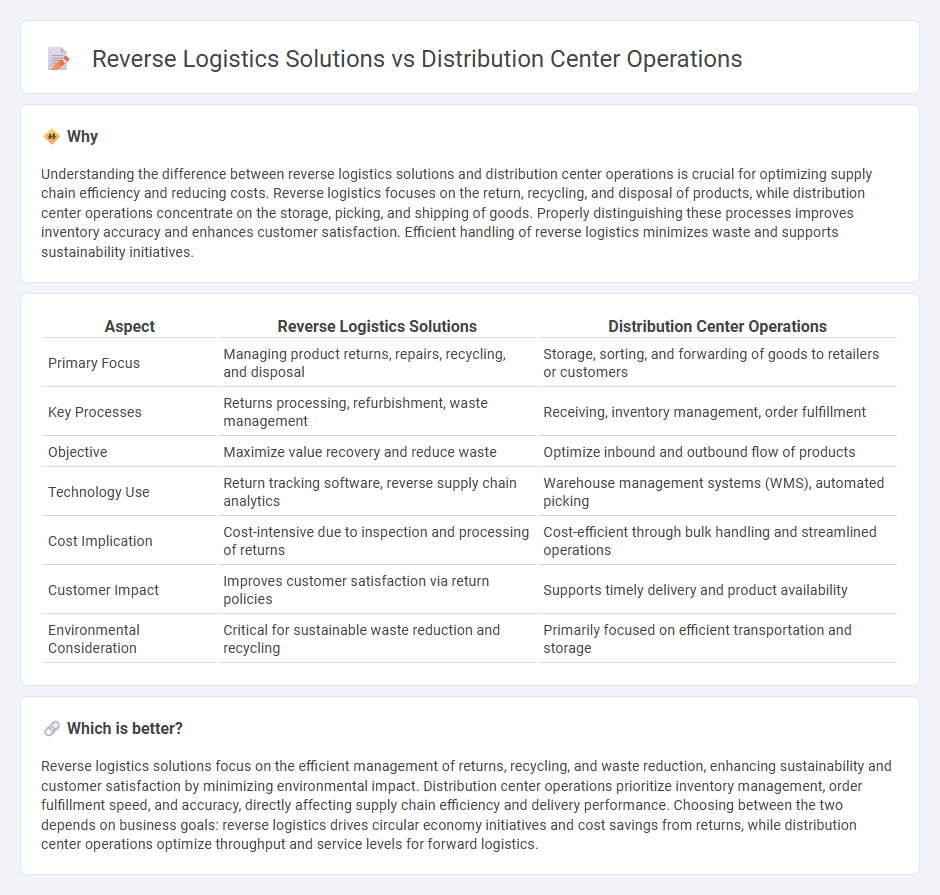

Understanding the difference between reverse logistics solutions and distribution center operations is crucial for optimizing supply chain efficiency and reducing costs. Reverse logistics focuses on the return, recycling, and disposal of products, while distribution center operations concentrate on the storage, picking, and shipping of goods. Properly distinguishing these processes improves inventory accuracy and enhances customer satisfaction. Efficient handling of reverse logistics minimizes waste and supports sustainability initiatives.

Comparison Table

| Aspect | Reverse Logistics Solutions | Distribution Center Operations |

|---|---|---|

| Primary Focus | Managing product returns, repairs, recycling, and disposal | Storage, sorting, and forwarding of goods to retailers or customers |

| Key Processes | Returns processing, refurbishment, waste management | Receiving, inventory management, order fulfillment |

| Objective | Maximize value recovery and reduce waste | Optimize inbound and outbound flow of products |

| Technology Use | Return tracking software, reverse supply chain analytics | Warehouse management systems (WMS), automated picking |

| Cost Implication | Cost-intensive due to inspection and processing of returns | Cost-efficient through bulk handling and streamlined operations |

| Customer Impact | Improves customer satisfaction via return policies | Supports timely delivery and product availability |

| Environmental Consideration | Critical for sustainable waste reduction and recycling | Primarily focused on efficient transportation and storage |

Which is better?

Reverse logistics solutions focus on the efficient management of returns, recycling, and waste reduction, enhancing sustainability and customer satisfaction by minimizing environmental impact. Distribution center operations prioritize inventory management, order fulfillment speed, and accuracy, directly affecting supply chain efficiency and delivery performance. Choosing between the two depends on business goals: reverse logistics drives circular economy initiatives and cost savings from returns, while distribution center operations optimize throughput and service levels for forward logistics.

Connection

Reverse logistics solutions integrate seamlessly with distribution center operations by managing product returns, refurbishments, and recycling processes within the facility. Efficient coordination enhances inventory accuracy, reduces processing time, and lowers overall supply chain costs. Advanced warehouse management systems facilitate real-time tracking of returned goods, optimizing reverse flow and maintaining distribution center productivity.

Key Terms

**Distribution Center Operations:**

Distribution center operations streamline inventory management, order fulfillment, and shipping processes to optimize supply chain efficiency and reduce operational costs. Advanced technologies such as warehouse management systems (WMS) and automation enhance accuracy and speed in sorting, picking, and packing activities. Discover how integrating these solutions can transform your distribution center performance.

Order Fulfillment

Distribution center operations optimize inventory management and streamline order fulfillment through efficient picking, packing, and shipping processes. Reverse logistics solutions handle returns processing, refurbishment, and disposal, enhancing customer satisfaction and reducing waste. Explore the key differences to improve your supply chain strategy and order fulfillment efficiency.

Inventory Management

Distribution center operations streamline inventory management through efficient order fulfillment, real-time stock tracking, and optimized storage solutions that reduce handling times and improve accuracy. Reverse logistics solutions prioritize the efficient processing of returned goods, refurbishment, and resale, ensuring the inventory cycle is closed with minimized waste and enhanced sustainability. Explore the distinct strategies each approach employs to maximize inventory control and operational efficiency.

Source and External Links

Distribution Center Benefits and Key Processes Explained - ShipBob - Distribution center operations include receiving and storing inventory, picking and packing orders, and shipping packages efficiently using warehouse management systems to improve speed and accuracy.

Distribution Centers Explained - NetSuite - Distribution centers receive, organize, and ship products to stores or customers, often using strategies like cross-docking to speed delivery, with operations tailored to industry demands and supported by supply chain and inventory management.

Logistics Distribution Center (DC): What is it and its functions? - Distribution centers focus on quick reception of goods, short-term storage with high product turnover, and rapid order preparation and shipment, utilizing specialized warehouse areas and storage systems like FIFO for efficient flow.

dowidth.com

dowidth.com